Reboiler

A reboiler and cylinder technology, applied in the field of reboilers, can solve the problems of easy scaling on the boiling side of the heat exchange tube, high power and material consumption, low heat transfer efficiency of the heat exchange tube, etc., and achieve improved boiling heat transfer , Improve condensation effect, reduce operating cost and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

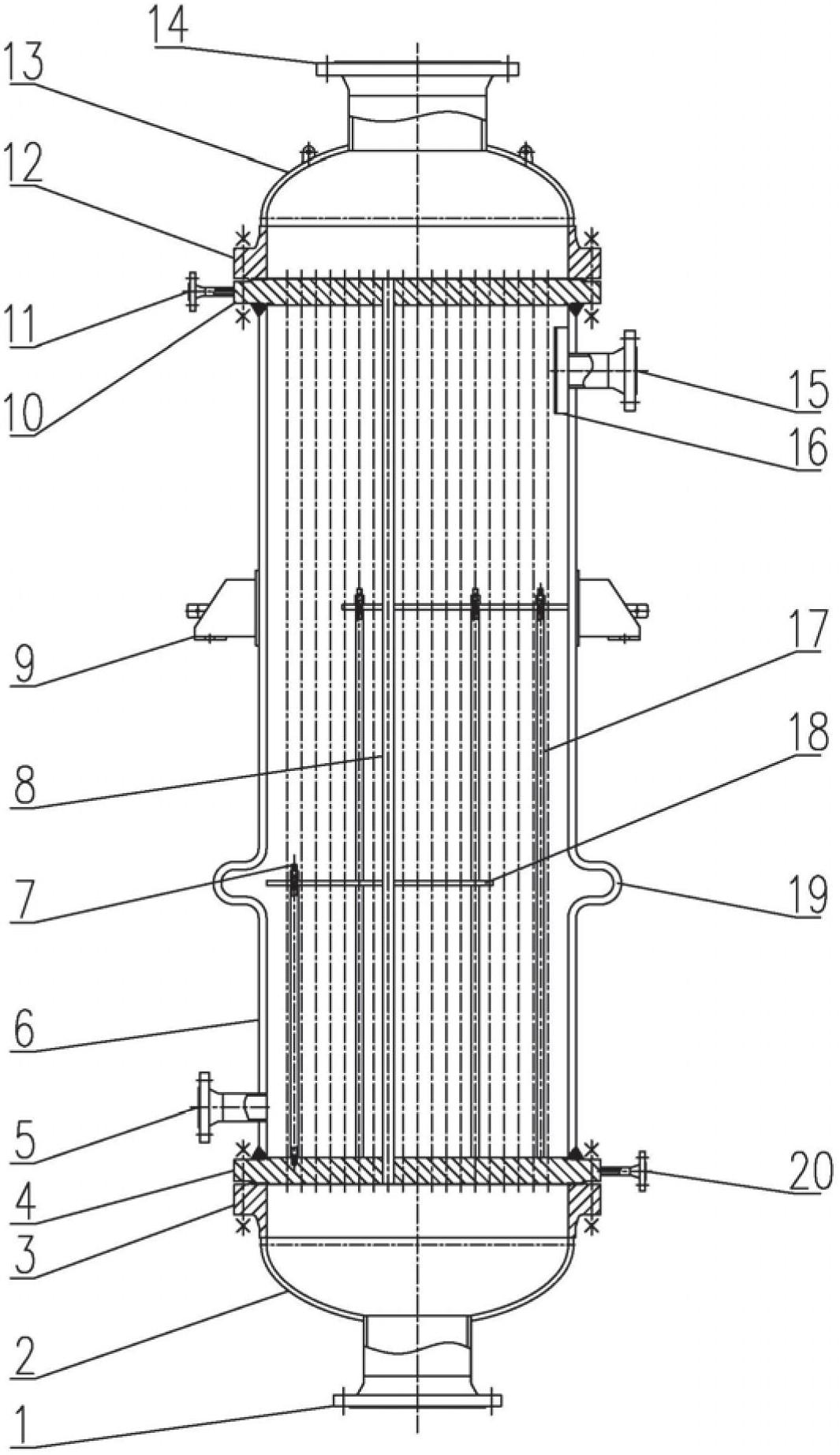

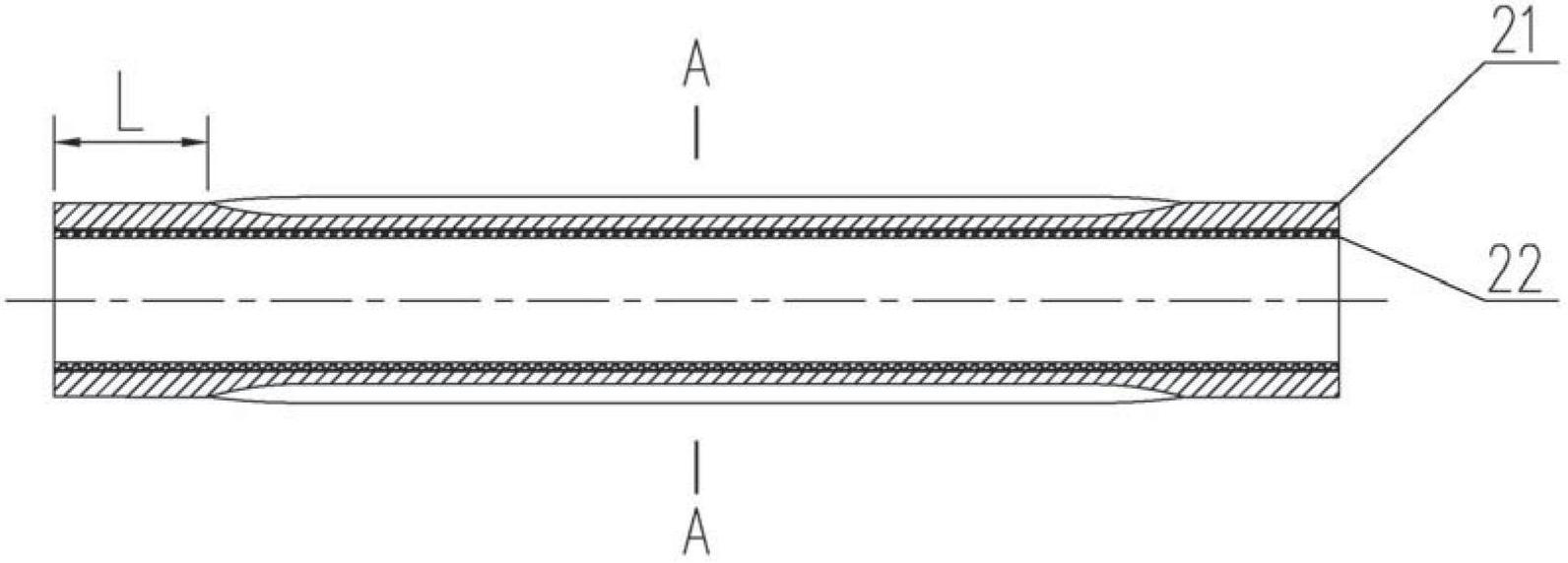

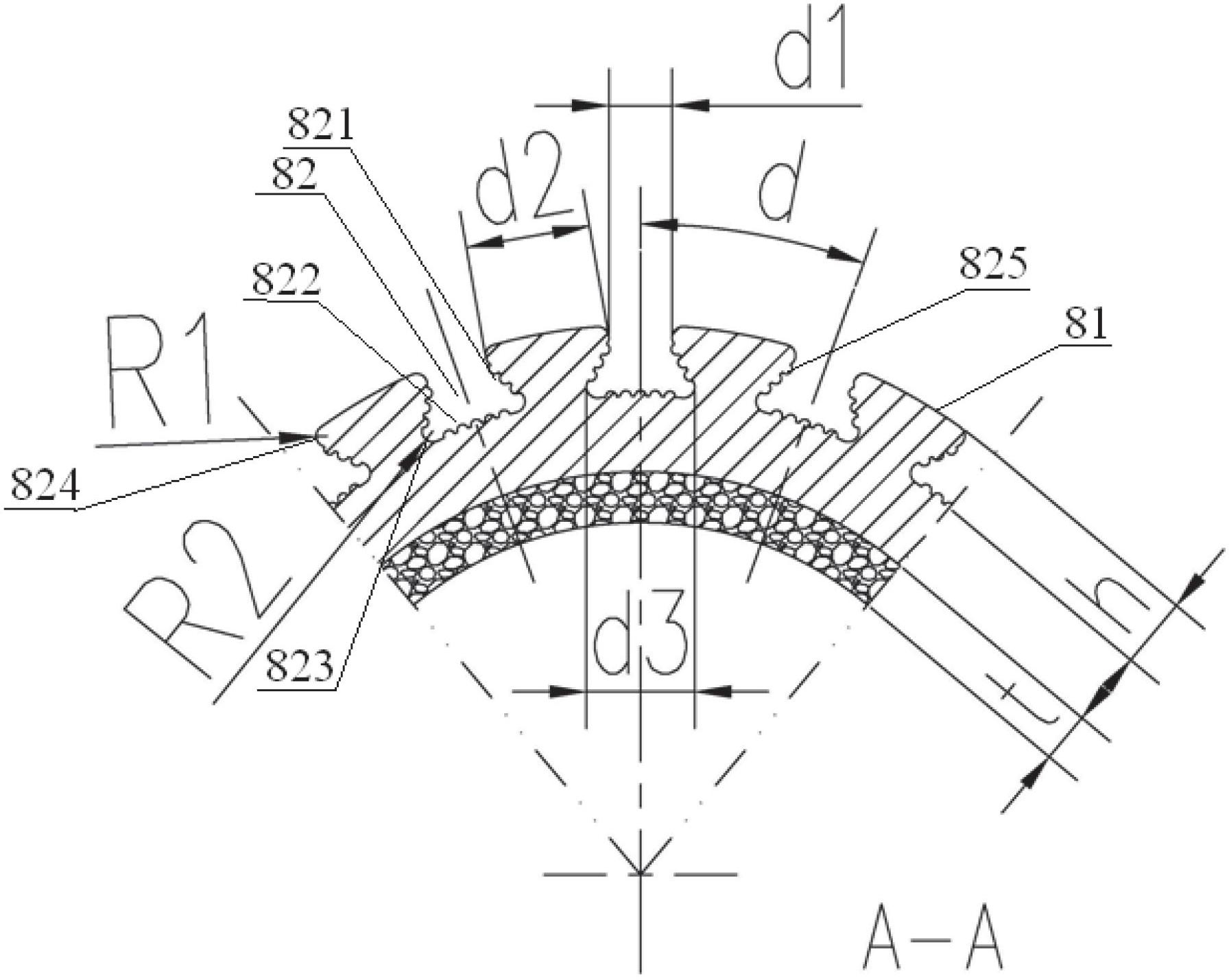

[0025] Such as figure 1 , figure 2 with image 3 As shown, the present invention provides a reboiler, comprising: a cylinder 6, the two ends of the cylinder respectively have a material inlet and a material outlet, and the cylinder also has a steam inlet on the side of the material outlet , and there is a condensate outlet on the side of the material inlet; a plurality of heat exchange tubes, the plurality of heat exchange tubes are arranged side by side in the cylinder, wherein the heat exchange tubes include a matrix and a porous layer, so The porous layer is located on the inner surface of the base body, the thickness of the porous layer is 0.1-0.5 mm, and the porosity is 30-60%. The outer surface of the middle part of the base body is provided with a plurality of longi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com