Indium oxide sintered body and indium oxide transparent conductive film

一种透明导电膜、烧结体的技术,应用在氧化物导体、绝缘载体上的导电层、非金属导体等方向,能够解决长波长区域透射率低等问题,达到低电阻率、有效利用、提高转换效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Indium oxide (In 2 o 3 ) raw material powder and niobium oxide (Nb 2 o 5 ) powder, mixed in air at 3000 rpm for 3 minutes rotation time using a high-speed mixer.

[0071] Then, the mixed powder was put into an attritor together with zirconia microspheres, and finely pulverized at a rotation speed of 300 rpm for 3 hours to adjust the average particle diameter (D50) to 0.8 μm. The amount of water was adjusted to form finely pulverized raw materials into a slurry with a solid content of 50%, and the inlet temperature was set to 200°C, and the outlet temperature was set to 120°C for granulation.

[0072] Then, at 600kgf / cm 2 After the granulated powder is pressed and shaped under the condition of keeping the surface pressure for 1 minute, use an isostatic pressing device (CIP) at 1800kgf / cm 2 The surface pressure is maintained for 1 minute for forming. Then, this molded product was held in an electric furnace at 1550° C. for 20 hours in an oxygen atmosphere to perform...

Embodiment 2~4、 comparative example 1~2

[0078] The method of manufacturing the sintered body and the method of manufacturing the transparent conductive film were the same as in Example 1, except that the ratio of the atomic concentration (number of atoms) of niobium was changed. That is, in Example 2, the atomic concentration of niobium was 2.0%, in Example 3 the atomic concentration of niobium was 3.0%, and in Example 4 the atomic concentration of niobium was 4.0%. In addition, in Comparative Example 1, the atomic concentration of niobium was 0.5%, and in Comparative Example 2, the atomic concentration of niobium was 5.0%.

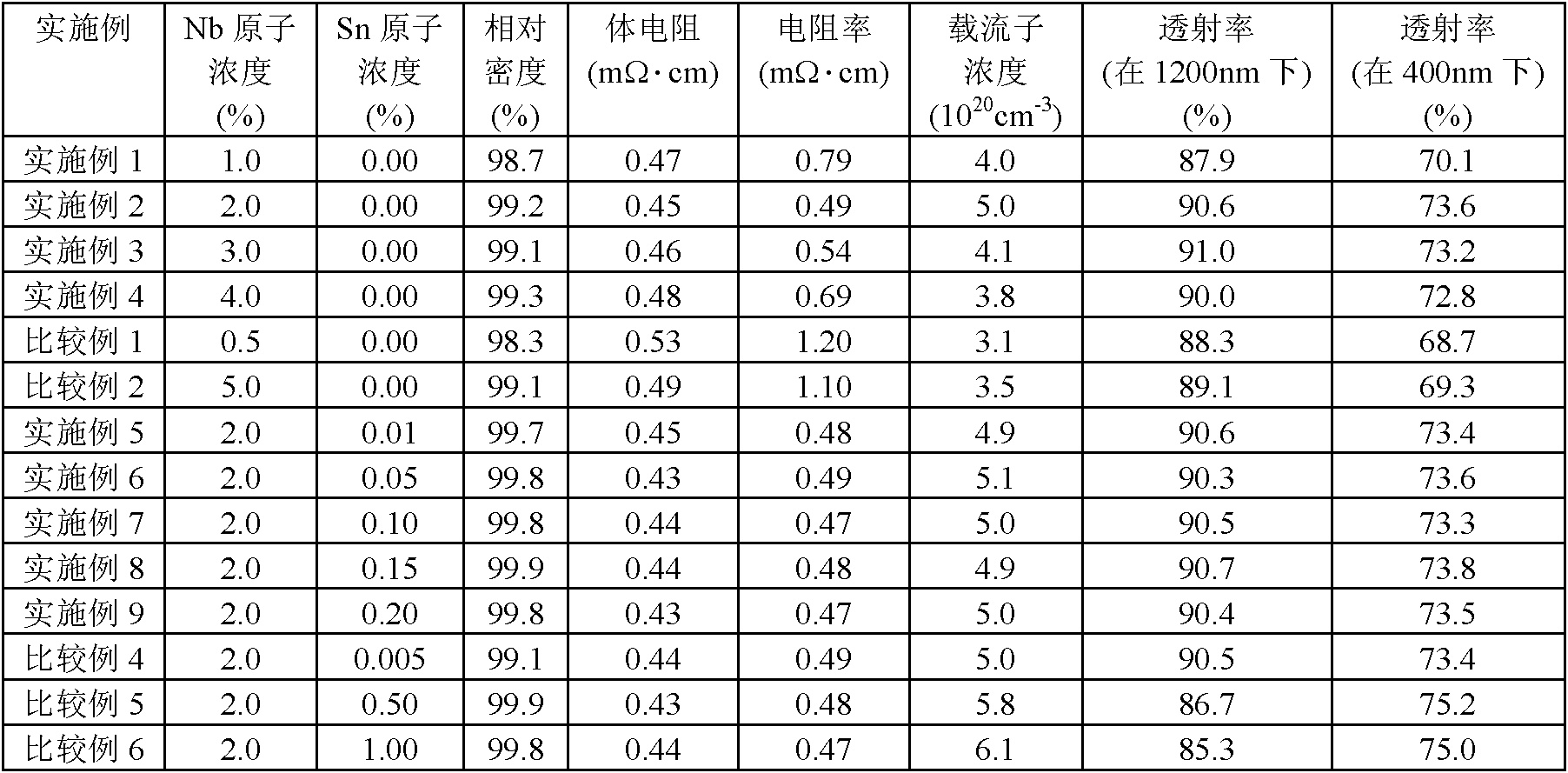

[0079] Table 1 shows the results of properties of the obtained sintered body and film. From these results, it can be seen that when the ratio of the atomic number of niobium is out of the range of 1 to 4%, the specific resistance becomes high, so that the property as a transparent conductive film is not preferable. In addition, it can be seen that although tin is not added, the relative densit...

Embodiment 5~9、 comparative example 4~6

[0083] The production method of the sintered body and the production method of the transparent conductive film were the same as in Example 1, except that the ratio of the atomic number of niobium was set to 2.0%, and the ratio of the atomic concentration of tin was changed. That is, the atomic concentration of tin in Example 5 is 0.01%, the atomic concentration of tin in Example 6 is 0.05%, the atomic concentration of tin in Example 7 is 0.10%, and the atomic concentration of tin in Example 8 is The atomic concentration of tin in Example 9 was 0.15%. In addition, the atomic concentration of tin in Comparative Example 4 was 0.005%, the atomic concentration of tin in Comparative Example 5 was 0.50%, and the atomic concentration of tin in Comparative Example 6 was 1.00%. The results of the characteristics of the obtained sintered bodies and films are also listed in Table 1.

[0084] From these results, it can be seen that although the relative density is 98.7% when the tin conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative density | aaaaa | aaaaa |

| relative density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com