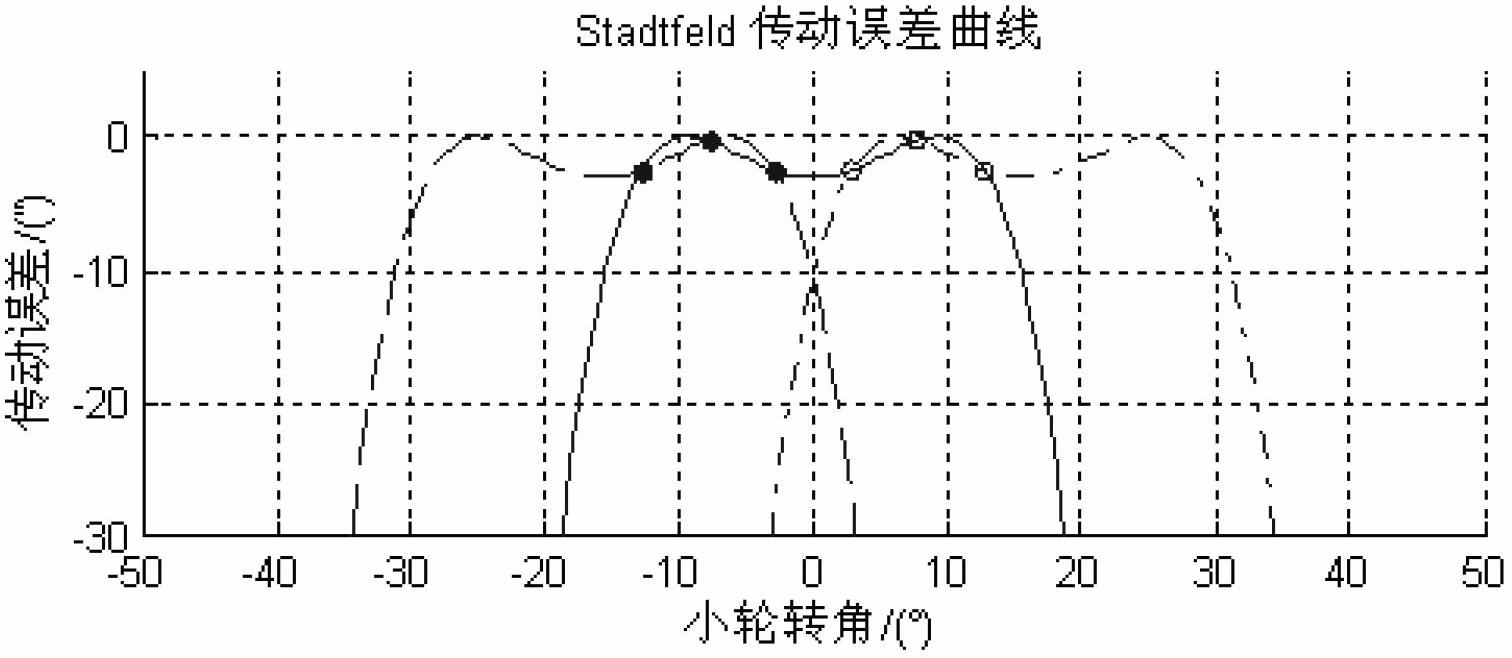

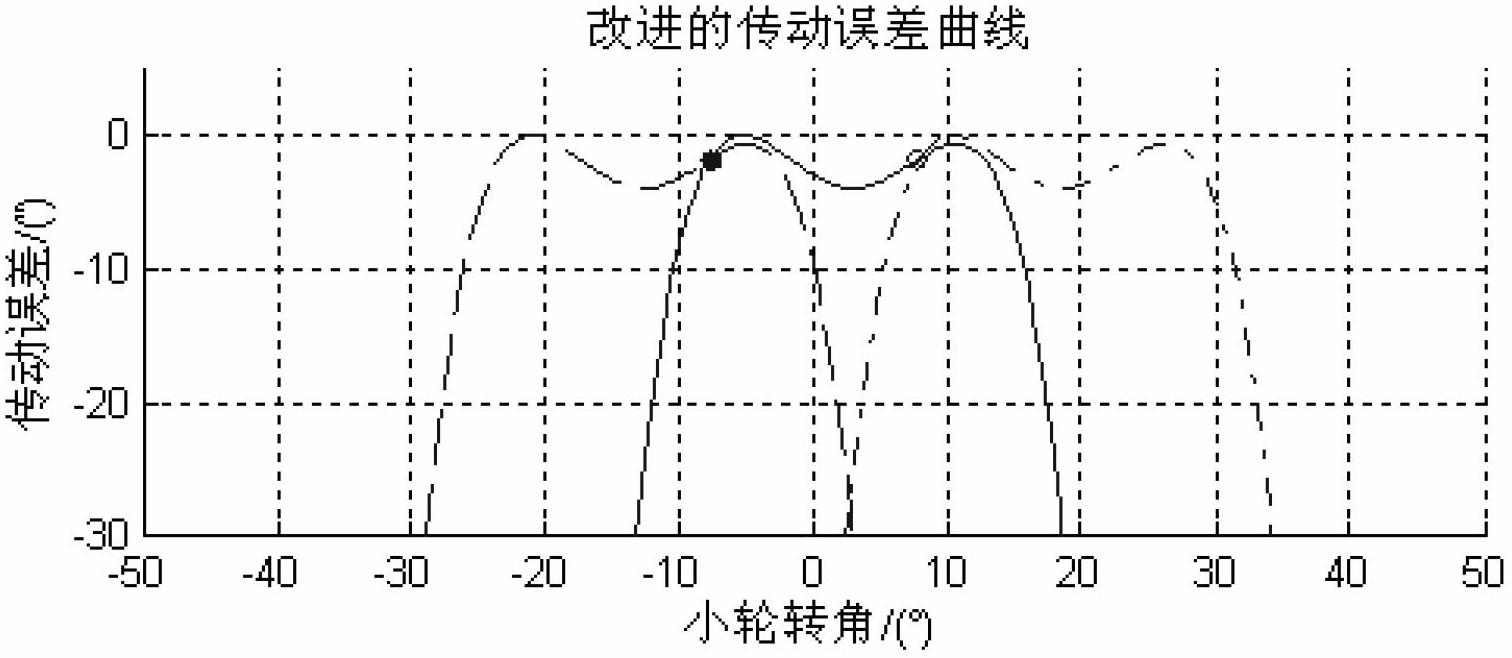

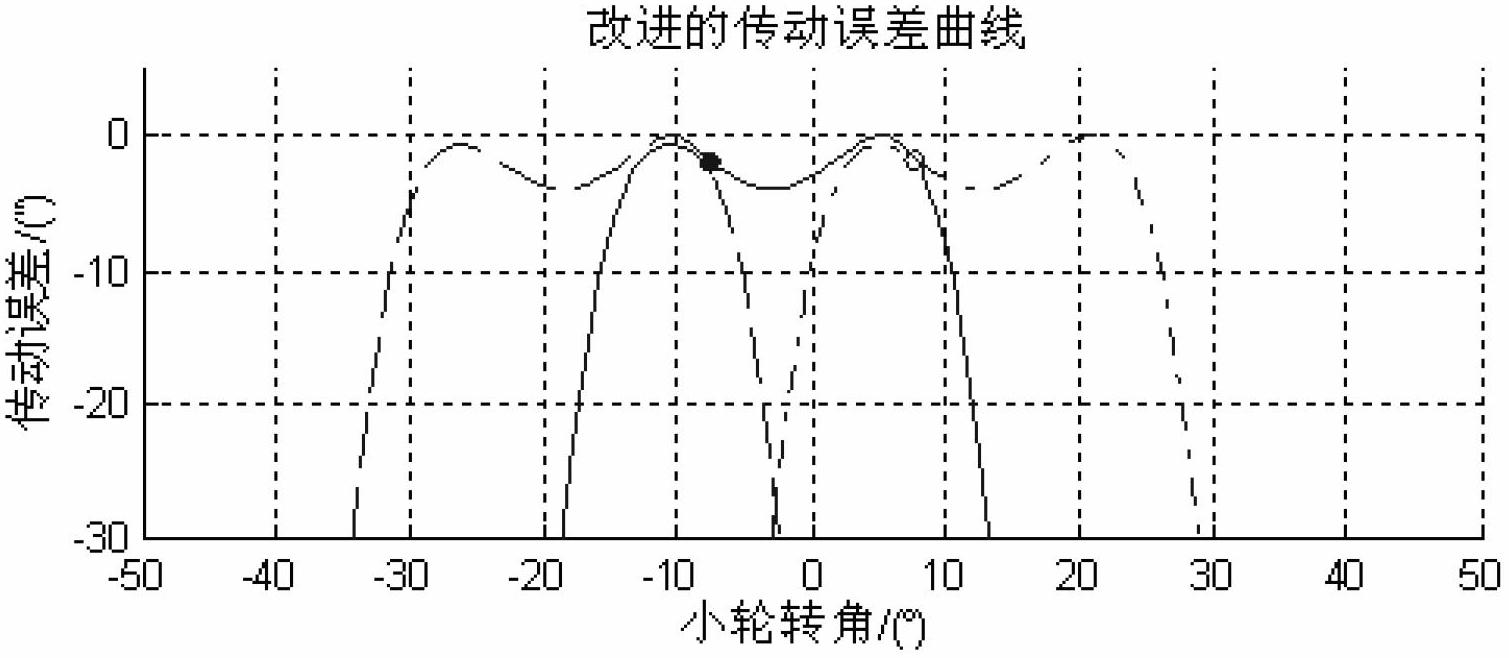

Four-stage transmission error curve of spiral bevel gear and design method thereof

A technology of spiral bevel gears and transmission errors, which is applied to components with teeth, belts/chains/gears, mechanical equipment, etc., and can solve problems such as large relative speed steps and tooth-changing impacts that have not been well resolved , to achieve the effect of avoiding fluctuations, improving transmission performance, and improving transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Describe the present invention below in conjunction with specific embodiment:

[0044] 1. The basic principle of transmission error

[0045] 1.1, the formation principle of transmission error

[0046] The spiral bevel gear is a point contact local conjugate transmission, and the transmission error is defined as

[0047]

[0048] In the formula ——The actual corner of the small wheel and the big wheel

[0049] ——The actual rotation angle of the small wheel and the large wheel when the reference point of the tooth surface meshes

[0050] z 1 ,z 2 ——The number of teeth of the small wheel and the big wheel

[0051] The first term in formula (1) is the rotation angle of the bull wheel when it meshes with the reference point, is the rotation angle of the small wheel when meshing relative to the reference point, is the nominal rotation angle of the bull wheel determined according to the nominal transmission ratio. Among them, the relative rotation angle of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com