A design method of synchronous motion transmission error curve and spiral bevel gear

A transmission error and synchronous motion technology, which is applied in the field of spiral bevel gears, can solve the problems that the impact of changing gears has not been well resolved, and the superiority of the fourth-order transmission error curve has not been fully utilized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

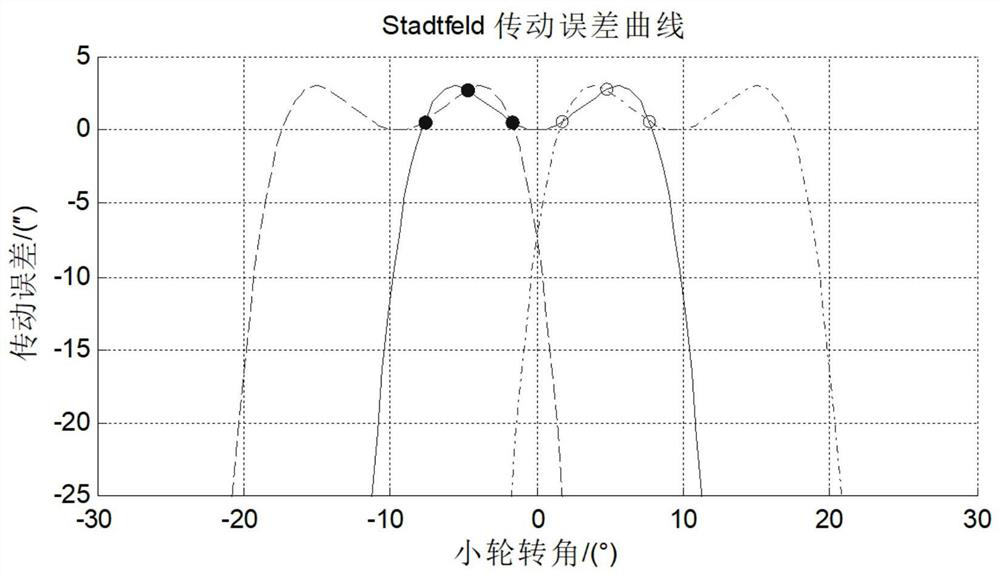

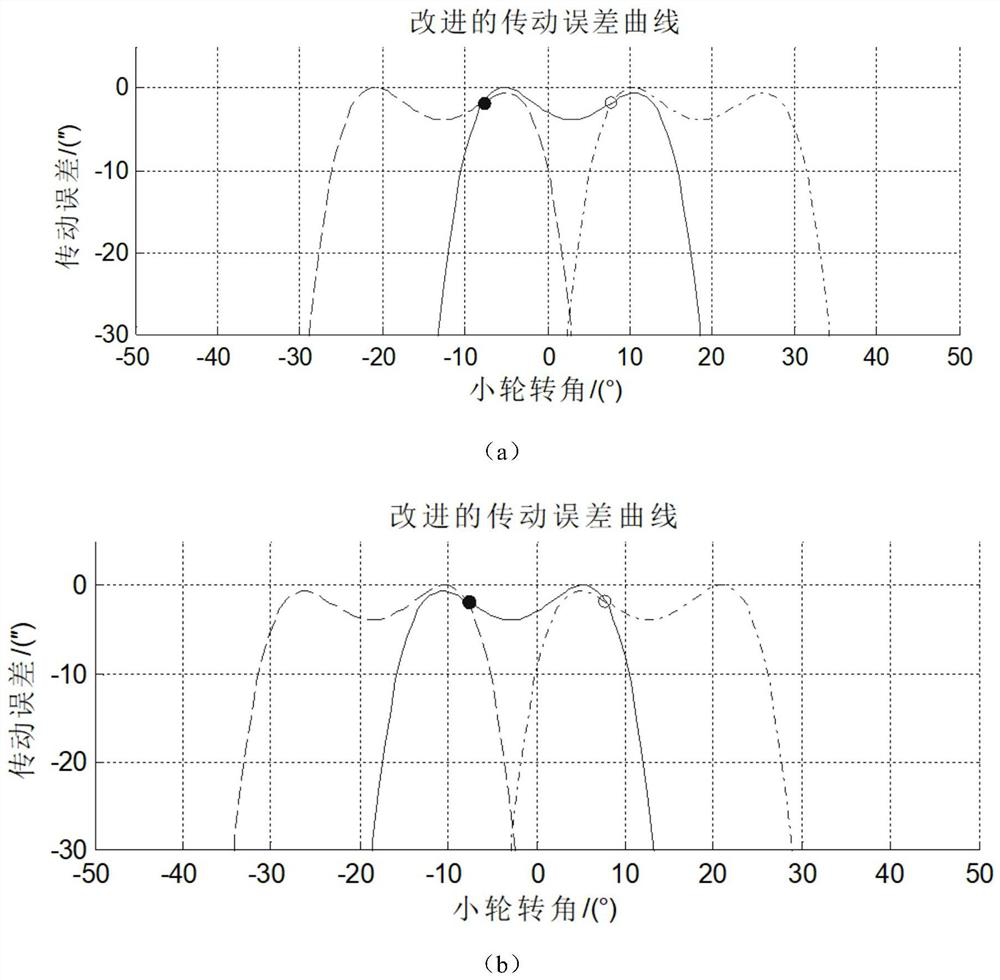

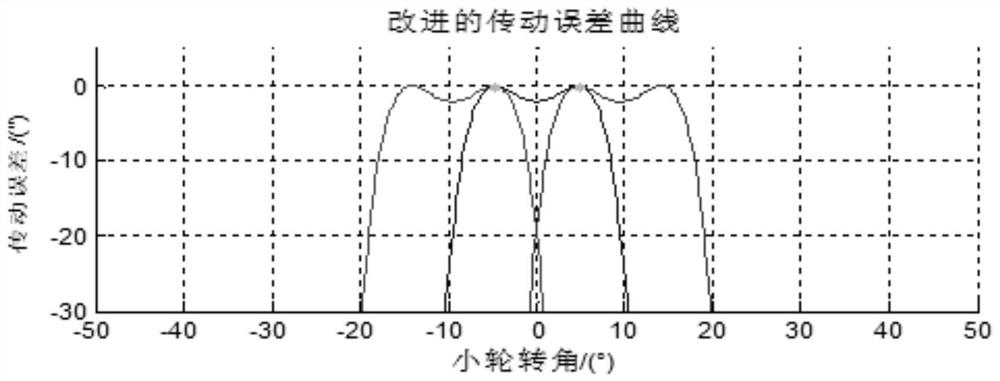

[0073] (1) The formation principle of transmission error

[0074] The spiral bevel gear is a point contact local conjugate transmission, and the transmission error is defined as

[0075]

[0076] In the formula ——The actual rotation angle of driving wheel and driven wheel

[0077] ——The actual rotation angle of the driving wheel and the driven wheel when the reference point of the tooth surface meshes

[0078] z 1 ,z 2 ——The number of teeth of driving wheel and driven wheel

[0079] The first term in formula (1) is the rotation angle of the driven wheel when meshing relative to the reference point, is the rotation angle of the driving wheel when it is meshed relative to the reference point, is the theoretical rotation angle of the driven wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com