Boot-shaped profile line cam

A cam and shoe-shaped technology, applied in the direction of engine components, machines/engines, charging systems, etc., can solve the problems of increasing the control difficulty of the control system, excessive pollutant emissions, and loud engine operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is described in more detail below in conjunction with accompanying drawing example:

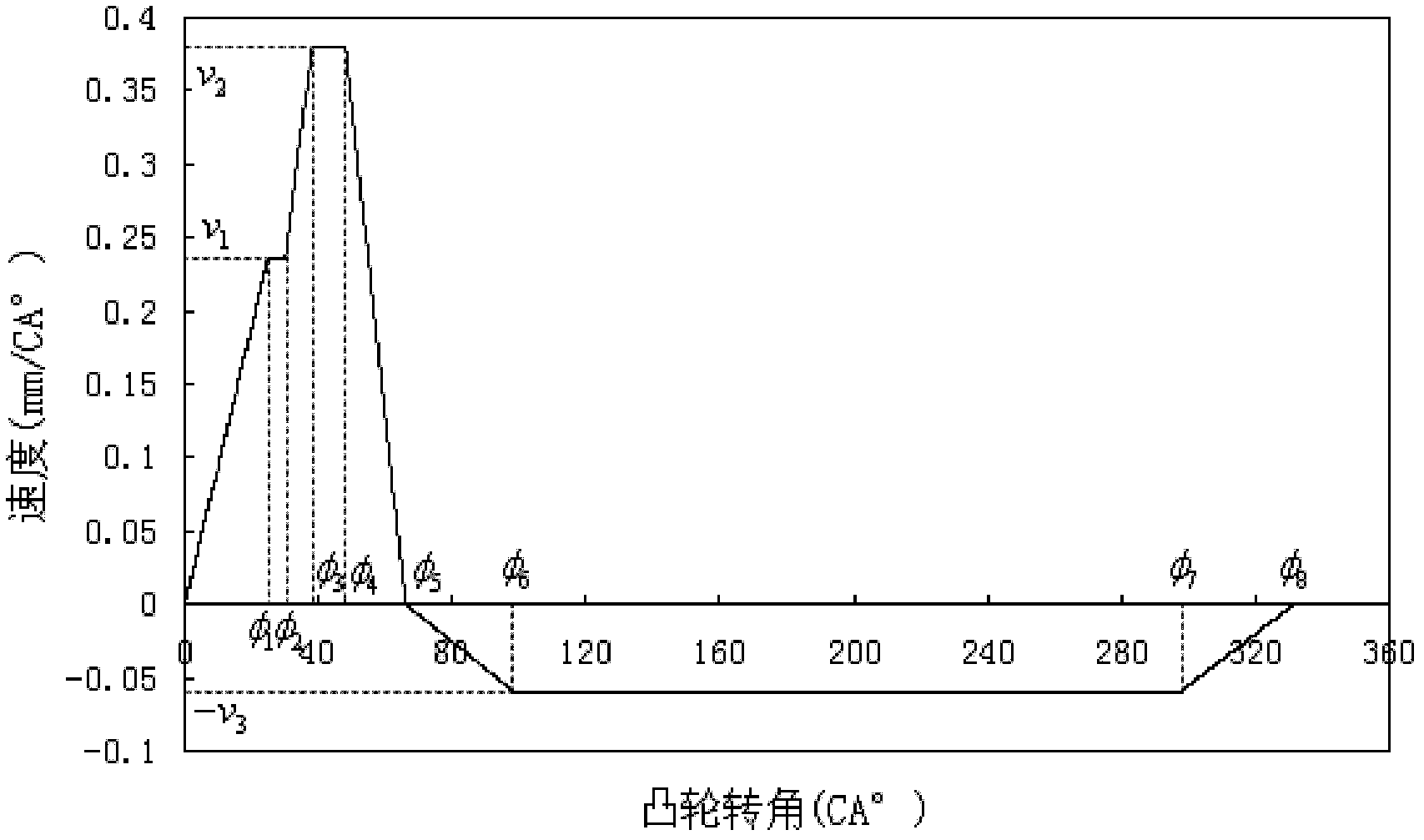

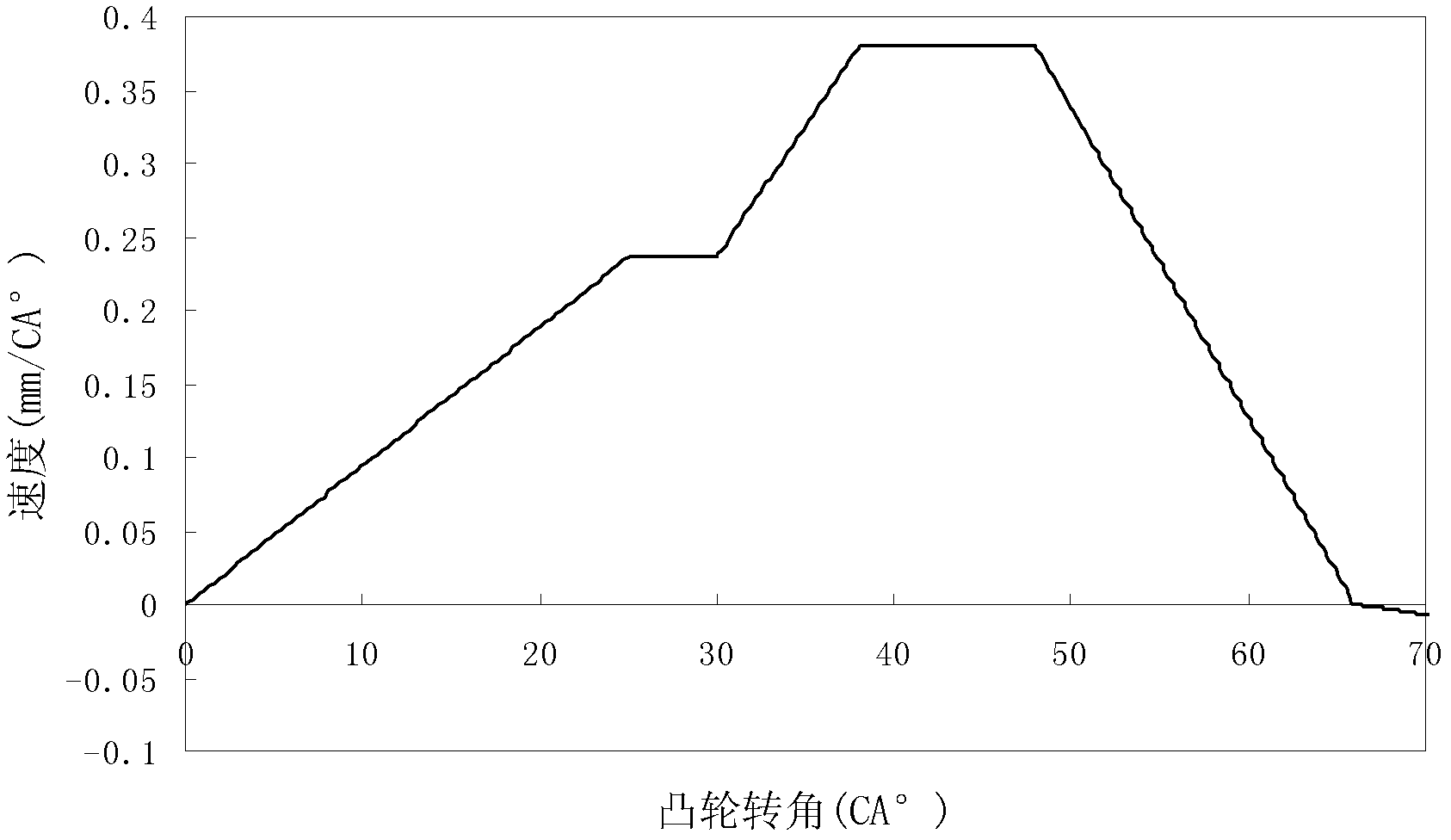

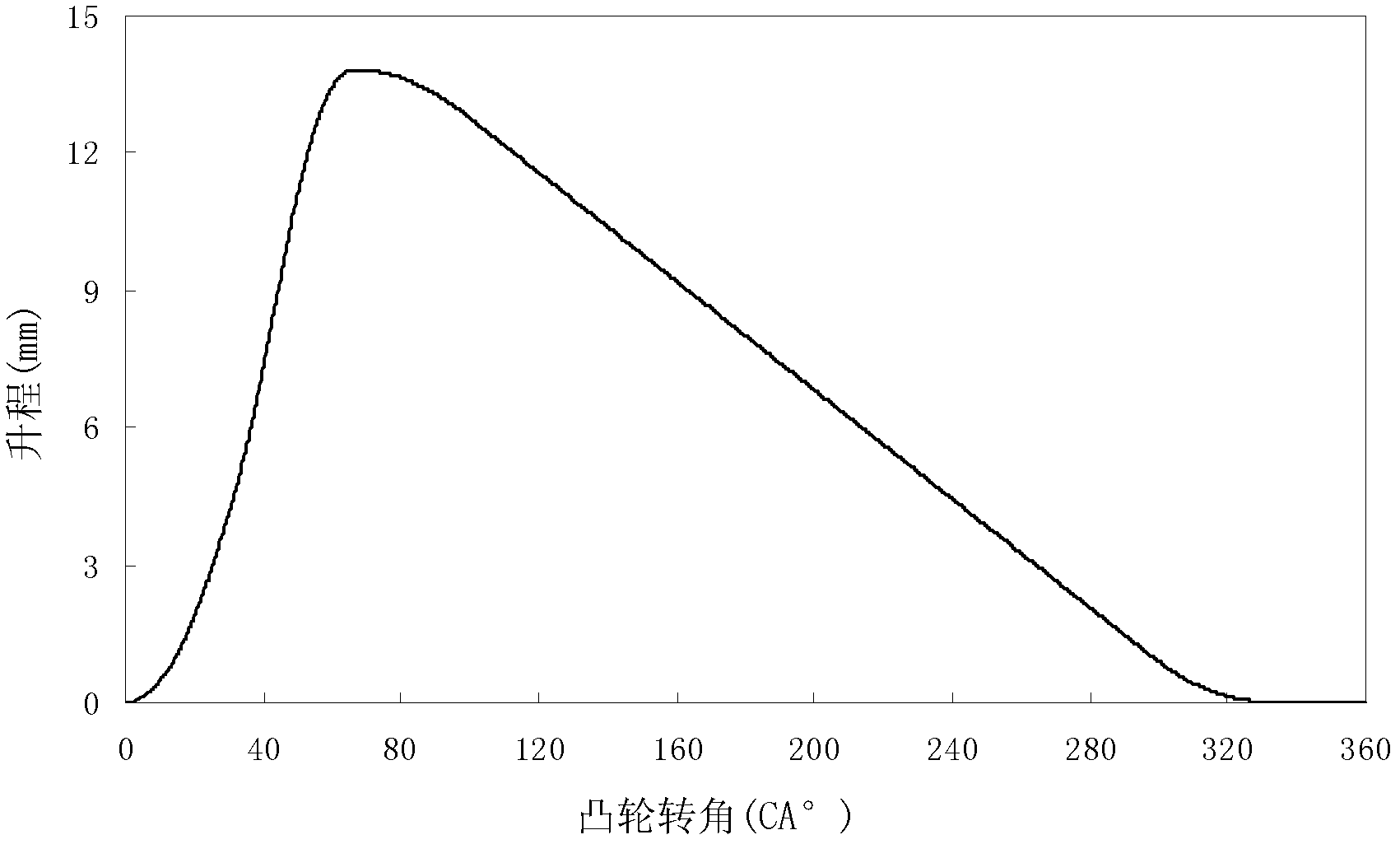

[0047] 1 to 3, the shoe cam profile of the present invention, its thrust section corresponds to the forward constant acceleration stage [0°, φ 1 ], working section [φ 1 , φ 4 ] and the forward and other deceleration stages [φ 4 , φ 5 ], the return section of the cam corresponds to the reverse constant acceleration stage of the plunger follower motion law [φ 5 , φ 6 ], reverse constant velocity stage [φ 6 , φ 7 ](velocity is v 3 ) and deceleration stages such as reverse [φ 7 , φ 8 ]. The cam working section includes two constant speed stages [φ 1 , φ 2](velocity is v 1 ) and [φ 3 , φ 4 ](velocity is v 2 ) and a constant acceleration stage [φ 2 , φ 3 ]. The equations of motion for each segment of the plunger follower are:

[0048] 1. Forward constant acceleration stage [0°, φ 1 ]

[0049] The rate parameter equation is: (φ∈[0°, φ 1 ])

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com