Special-shaped hollow PTT (polytrimethylene terephthalate) bulked yarn and preparation method thereof

A manufacturing method and carpet yarn technology, which are applied in hollow filament manufacturing, rayon manufacturing, yarn and other directions, can solve the problem of difficult rapid expansion of PTT carpet yarn, and achieve the effect of simple manufacturing method and good anti-fouling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

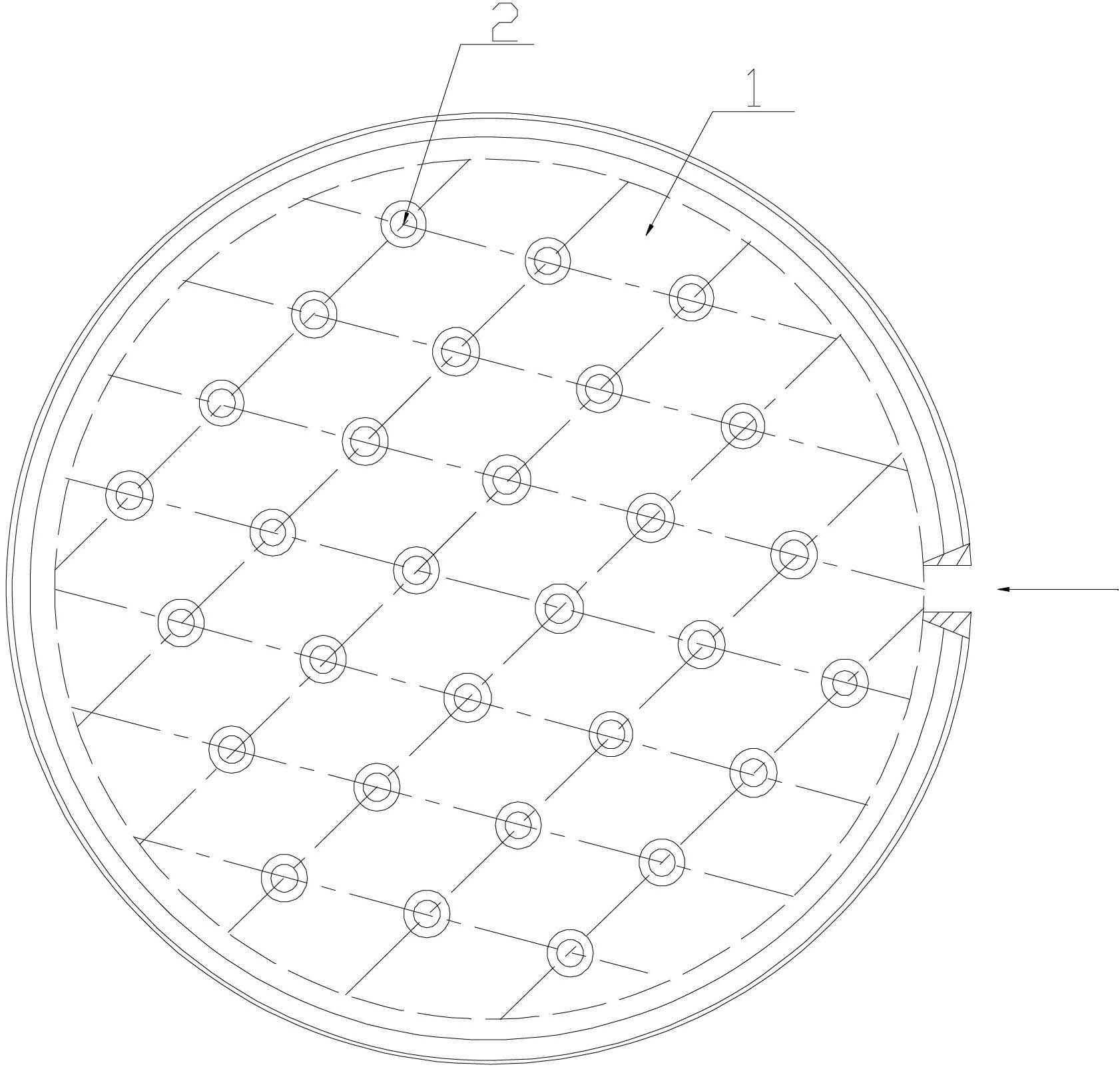

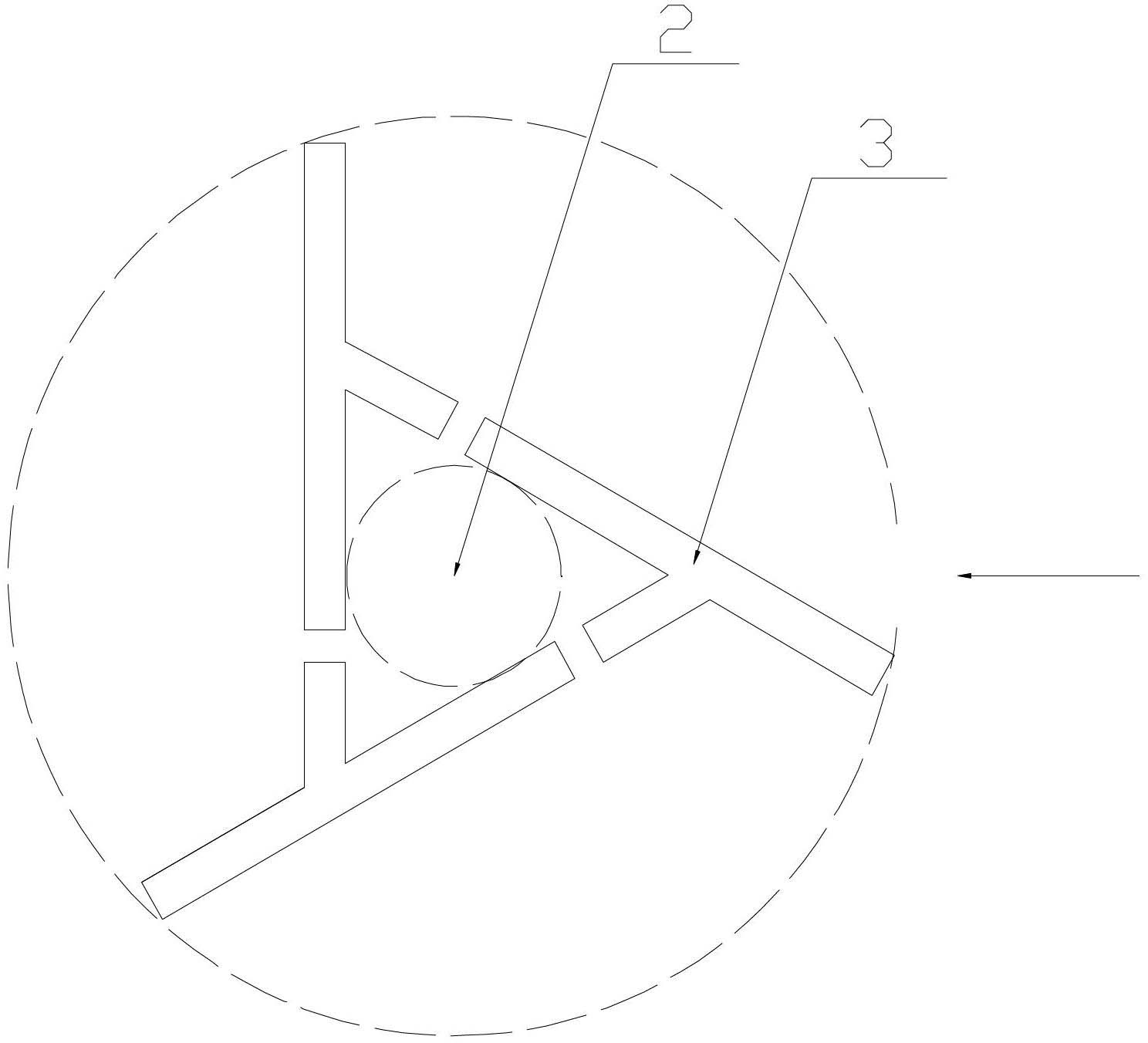

[0037] A single-screw BCF spinning unit is used for spinning at a spinning speed of 2300m / min, and a spinneret with 30 holes / trilobal triangular ring holes, PTT slices and special oil for PTT are used.

[0038] Process: Pre-dry the PTT slices until the water content is 15ppm~50ppm, transport them into the entrance of the screw extruder through a fully enclosed short-distance pipeline, melt the dried PTT slices through the screw, push the screw through the conduit, and send them into spinning The box body, the screw extrusion temperature is 250 ° C, the extrusion pressure is 76 bar, the melt is metered and transported to the spinneret in the box body by the spinning pump, and the spinneret hole of the spinneret with 30 holes / three-lobe triangular ring hole The extruded melt stream is cooled and solidified into fibers by side blowing in the spinning window. The temperature of the spinning assembly is 260°C, the spinning pressure is 30bar, the side blowing temperature is 16.5°C, a...

Embodiment 2

[0042] A single-screw BCF spinning unit is used for spinning at a spinning speed of 2000m / min, and a spinneret with 30 holes / trilobal triangular ring holes, PTT slices and special oil for PTT are used.

[0043] Process: Pre-dry the PTT slices until the water content is 15ppm-50ppm, transport them into the entrance of the screw extruder through a fully enclosed short-distance pipeline, melt the dried PTT slices through the screw, push the screw through the conduit, and send them into spinning The box body, the screw extrusion temperature is 260 ° C, the extrusion pressure is 80 bar, the melt is metered and transported to the spinneret in the box body by the spinning pump, and the spinneret hole of the spinneret with 30 holes / three-lobe triangular ring holes The extruded melt stream is cooled and solidified into fibers by side blowing in the spinning window. The temperature of the spinning assembly is 260°C, the spinning pressure is 33bar, the side blowing temperature is 15.5°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Stretch temperature | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com