Method for preparing bioethanol

A bio-ethanol and ethanol technology, applied in biochemical equipment and methods, microorganism-based methods, microorganisms, etc., can solve the problems of waste of xylose, slow growth rate, and inability to utilize xylose, so as to improve utilization efficiency and increase production. The effect of high rate and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The determination of embodiment 1 fermentation medium

[0026] According to the culture characteristics of cellulolytic microorganisms and oil-producing microorganisms, the formula of the mixed-bacteria fermentation medium was designed by using single-factor experiments and orthogonal experiments. According to the needs of microbial growth and metabolism, the fermentation medium is screened and designed as follows:

[0027] (1) Medium Ⅰ: 9g Na 2 HPO 4 12H 2 O, 1.5g KH 2 PO 4 , 1.2 mg FeNH 4 -Citrate, 0.34g (NH 4 ) 2 SO 4 , 0.15g peptone, 0.15g yeast extract, 0.3g CaCl 2 , 0.3g MgSO 4 , 0.005g FeSO 4 ·7H 2O, 0.0016g MnSO 4 ·H 2 O, 0.0014g ZnSO 4 ·H 2 O, 0.002g CoCl 2 , 1000mL H 2 O; pH is 4-6;

[0028] (2) Medium II: 2g KH 2 PO 4 , 1.4g (NH 4 ) 2 SO 4 , 0.3g MgSO 4 , 0.3g CaCl 2 , 0.5g peptone, 0.005g FeSO 4 ·7H 2 O, 0.0016g MnSO 4 ·H 2 O, 0.0014g ZnSO 4 ·H 2 O, 0.002g CoCl 2 , 1000mLH 2 O; pH is 4-6;

[0029] (3) Medium III: 1g peptone...

Embodiment 2

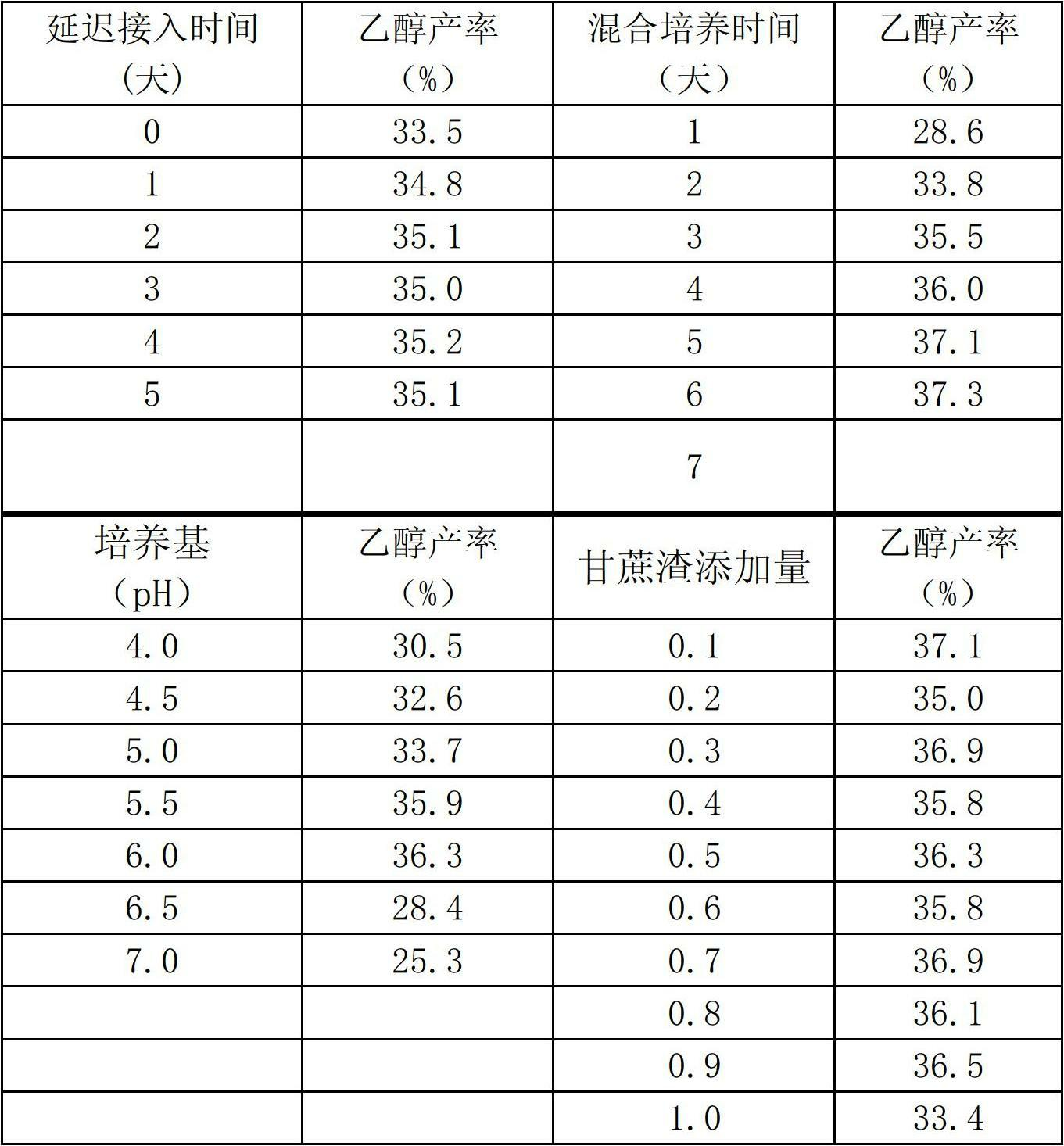

[0031] Embodiment 2 Fermentation condition investigation

[0032] (1) Activation of strains

[0033] Preparation of seed solution: Aspergillus niger (Aspergillus niger, DSMZ 821) was cultured in PDA medium at 25-30°C for 3-5 days at constant temperature

[0034] The ethanol-producing bacteria Candida shehatae (Candida shehatae, ATCC34887) was cultured in a YEPD medium at a constant temperature of 25-30°C for 3-5 days.

[0035] (2) mixed bacteria fermentation ethanol method

[0036] Respectively from the mixed ratio of strains (Aspergillus niger: Candida shohata, the biomass ratio is 1:0.5, 1:1 or 1:2 respectively.), the total inoculation amount, fermentation temperature and initial pH value of fermentation to ethanol obtained The influence of the rate is investigated to determine the relevant factors and their scope of influence. Based on the single factor experiment, the optimal level of the mixing ratio of strains, total inoculum, fermentation temperature and fermentation...

Embodiment 3

[0042] The preparation of embodiment 3 bioethanol

[0043] (1) Preparation of seed liquid: Aspergillus niger (DSMZ 821), which produces cellulase, was cultured at constant temperature in PDA medium to prepare Aspergillus niger seed liquid, and Candida shehatae (Candida shehatae, ATCC34887) The seed liquid of Candida shohata was obtained by constant temperature cultivation in YEPD medium, the cultivation temperature was 25-30° C., and the cultivation time was 3 days.

[0044] (2) Plant fibers such as straw and Aspergillus niger seed liquid were cultured in the medium (I) as described in Example 1 with constant temperature and shaking for 5 days, and the volume of Aspergillus niger seed liquid was 2% of the volume of the medium (I) ; Insert Candida shohata seed liquid, the biomass ratio of Aspergillus niger seed liquid and Candida shohata seed liquid is 1:0.5, continue constant temperature shaking culture for 3 days, culture temperature is 28 ℃, shaking speed 150r / min;

[0045...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com