Electrical equipment cleaning agent and preparation method thereof

A technology of electrical equipment and cleaning agents, applied in the field of chemical cleaning, to achieve the effects of large-scale industrial production, strong cleaning power, and simple and scientific mechanism of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

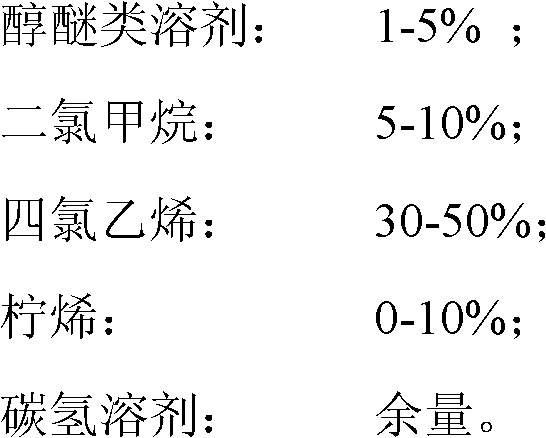

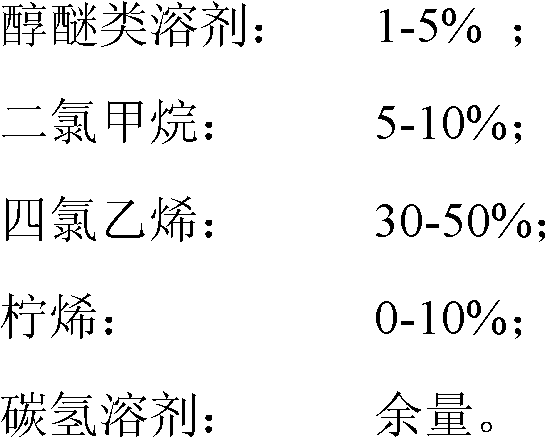

Method used

Image

Examples

Embodiment 1

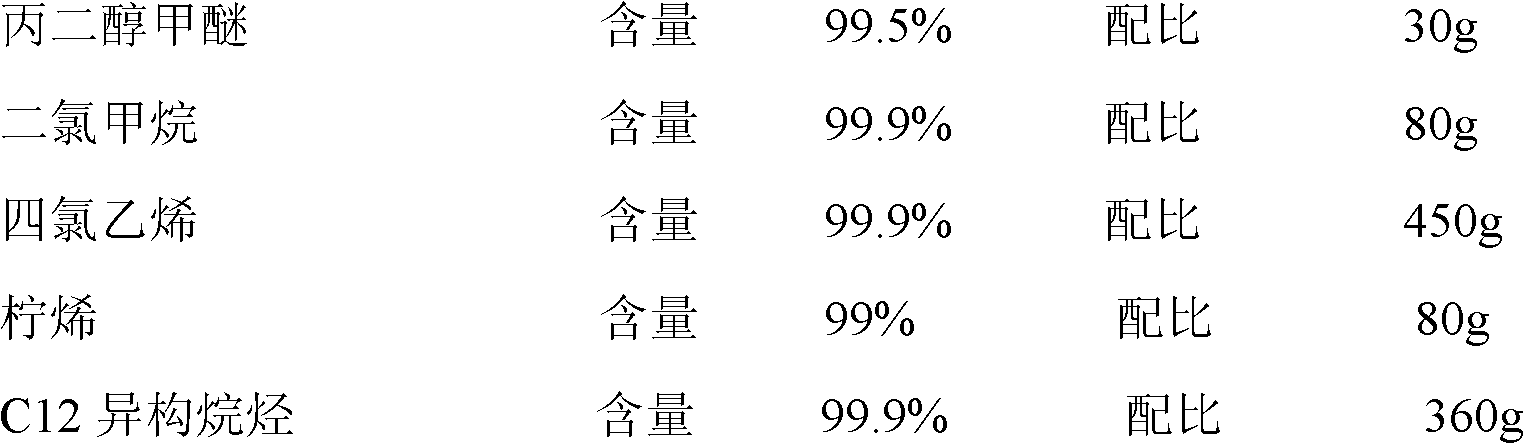

[0027] A kind of cleaning agent for electrical equipment, its composition and weight are as follows: (take 1000g product as example)

[0028]

[0029] A preparation method of cleaning agent for electrical equipment, the steps are as follows:

[0030] (1) Pump the C12 isoparaffin into the storage tank (the bottom is conical) and let it stand still for more than 24 hours to remove impurities and moisture at the bottom, and then pump it into the reaction kettle;

[0031] (2) propylene glycol methyl ether, methylene dichloride, tetrachloroethylene, limonene are added in the reactor successively;

[0032] (3) Stir the materials in the reaction kettle evenly for 20-30 minutes, and after passing through the dryer and filter, this product is the cleaning agent for electrical equipment.

[0033] The quality standard of cleaning agent for electrical equipment:

[0034] Appearance: colorless transparent liquid;

[0035] Odor: Slight solvent smell;

[0036] Specific gravity: 1.02g / ...

Embodiment 2

[0041] A kind of cleaning agent for electrical equipment, its composition and weight are as follows: (take 1000g product as example)

[0042] Propylene glycol methyl ether Content 99.5% Proportion 50g

[0043] Dichloromethane content 99% ratio 100g

[0044] Perchlorethylene content 99% ratio 500g

[0045] C9-C10 n-paraffin content 99.5% ratio 350g

[0046] (C9-C10 alkanes boiling range: 135-180°C, where C9 accounts for 20% by weight and C10 is 80%)

[0047] The steps of its preparation method are the same as in Example 1.

[0048] The quality standard of cleaning agent for electrical equipment:

[0049] Appearance: colorless transparent liquid

[0051] Specific gravity: 1.05g / ml

[0052] Withstanding voltage KV: ≥25

[0053] Flash point (opening): ≥70°C

[0054] ODP: 0.00;

[0055] Mechanism of action of the present invention:

[0056] Through the compound synergistic effect of alcohol ether solvent, methylene chloride, tetrachloroethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com