Method for synthesis of highly functionalized pyrrole compound

A synthetic method and highly functional technology, applied in organic chemistry and other directions, to achieve the effects of easy availability of raw materials and reagents, easy separation and purification, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

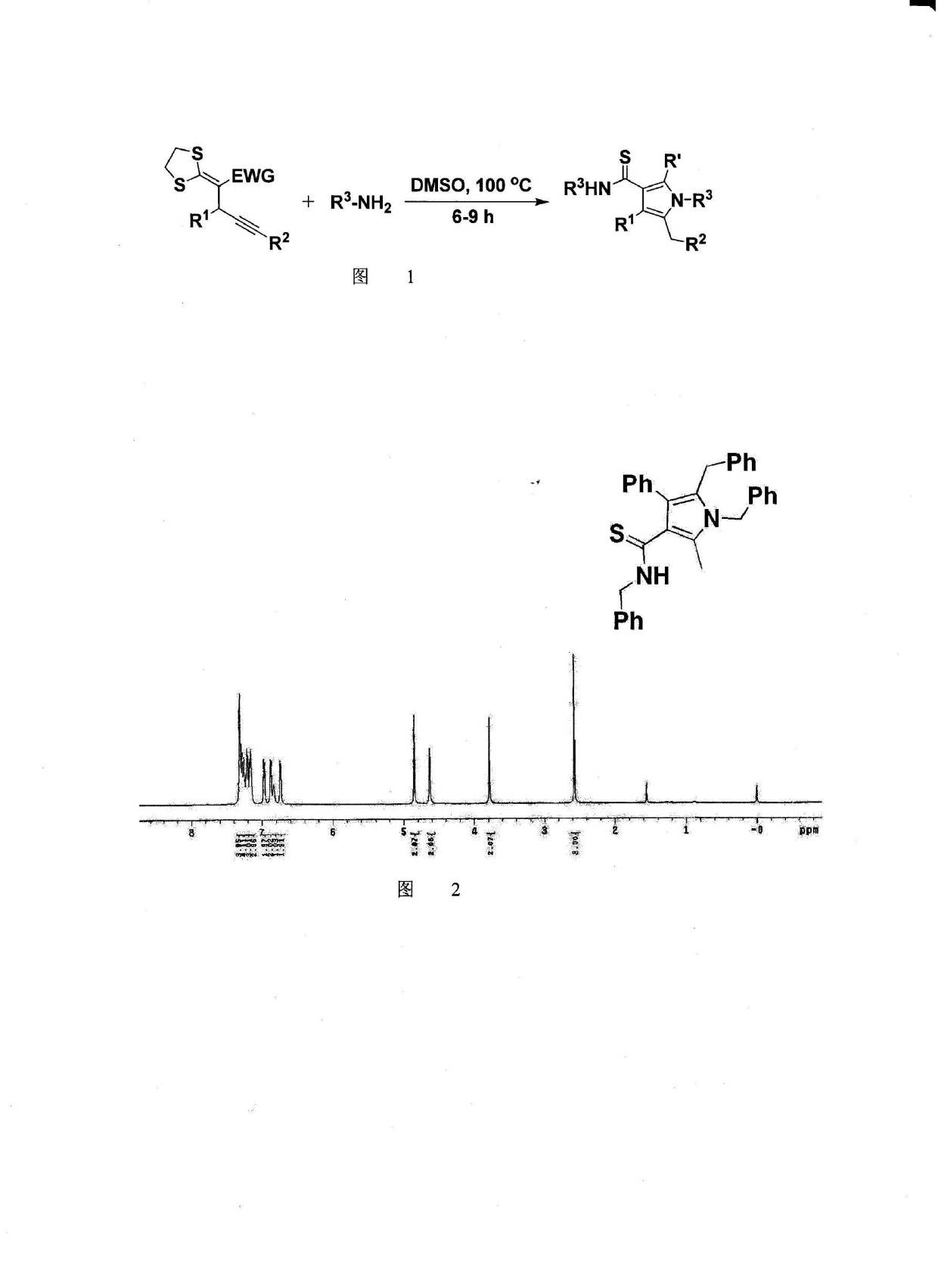

Method used

Image

Examples

Embodiment 1

[0024] 1) Dialkylthio substituted alkynes 1a preparation of

[0025]

[0026] Add acetonitrile (CH 3 CN) (4 mL), α-acetyl dithioketene (0.320g , 2.0 mmol) and 1,3-diphenylpropargyl alcohol (0.499g , 12 mmol), at room temperature 20°C, under stirring Next, TLC detects that the substrate disappears, and the reaction ends. The reaction solution was poured into saturated aqueous sodium chloride solution (10 mL), extracted with dichloromethane (3×10 mL), the organic phases were combined, dried with anhydrous calcium chloride, filtered, and then the organic solvent was distilled off under reduced pressure. Obtain solid mixture, through silica gel column chromatography (eluent is V 石油醚 : V 乙酸乙酯 = 10 : 3) 0.61g of white solid was obtained, and the structure of the product was confirmed by NMR and MS to be dialkylthio-substituted alkynes 1a , the yield is 88%.

[0027] 2) Pyrrole derivatives 2a preparation of

[0028]

[0029] To a 25 mL round bottom flask equipped with a...

Embodiment 2

[0033] use 1b Instead of the example 1 1a , the temperature is 80°C, other conditions are the same as Example 1, and the experimental results are shown in Table 1.

[0034]

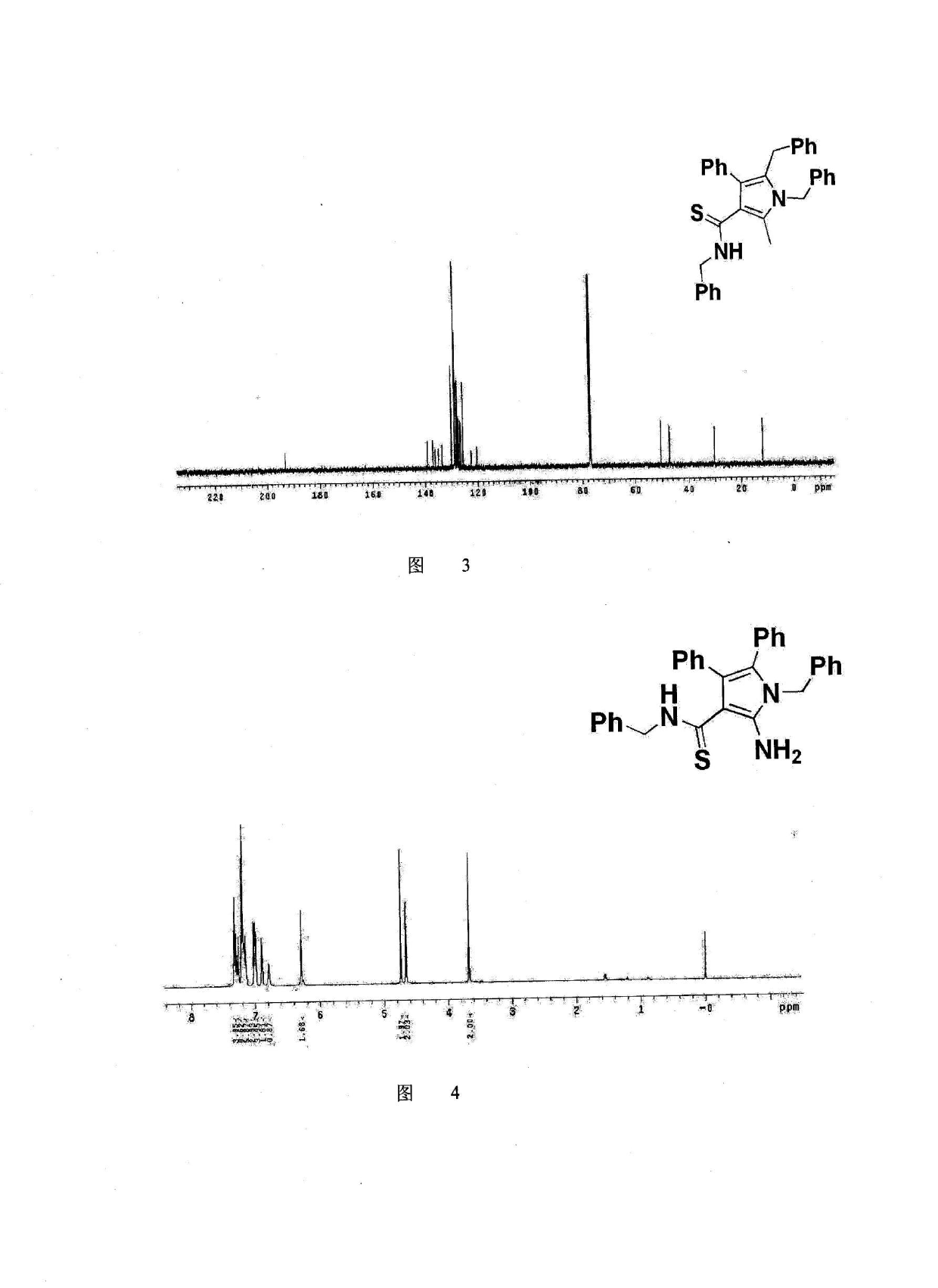

[0035] Spectral analysis data 2b :

[0036] 1 H-NMR (500 MHz, CDCl 3 ) δ 2.56 (s, 3H), 3.80 (s, 2H), 4.69 (d, J = 4.5 Hz, 2H), 4.85 (s, 2H), 6.85 (d, J = 7.5 Hz, 2H), 6.91-6.99 (m, 6H), 7.153-7.30 (m, 12H); 13 C-NMR (CDCl 3 , 125 MHz) δ 11.99, 30.38, 47.36, 50.50, 111.96, 122.92, 125.58, 126.14, 126.38, 127.38, 127.45, 127.64, 127.67, 127.90, 128.29, 128.57, 128.62, 128.85, 129.22, 133.81, 136.02, 136.24, 136.67 , 138.67, 192.56; HRMS (ESI) m / z calculated for C 31 h 29 N 2 S 2 [M+1] + : 493.1772 found: 493.1672.

Embodiment 3

[0038] use 1c Instead of the example 1 1a , the temperature is 120°C, other conditions are the same as Example 1, and the experimental results are shown in Table 1.

[0039]

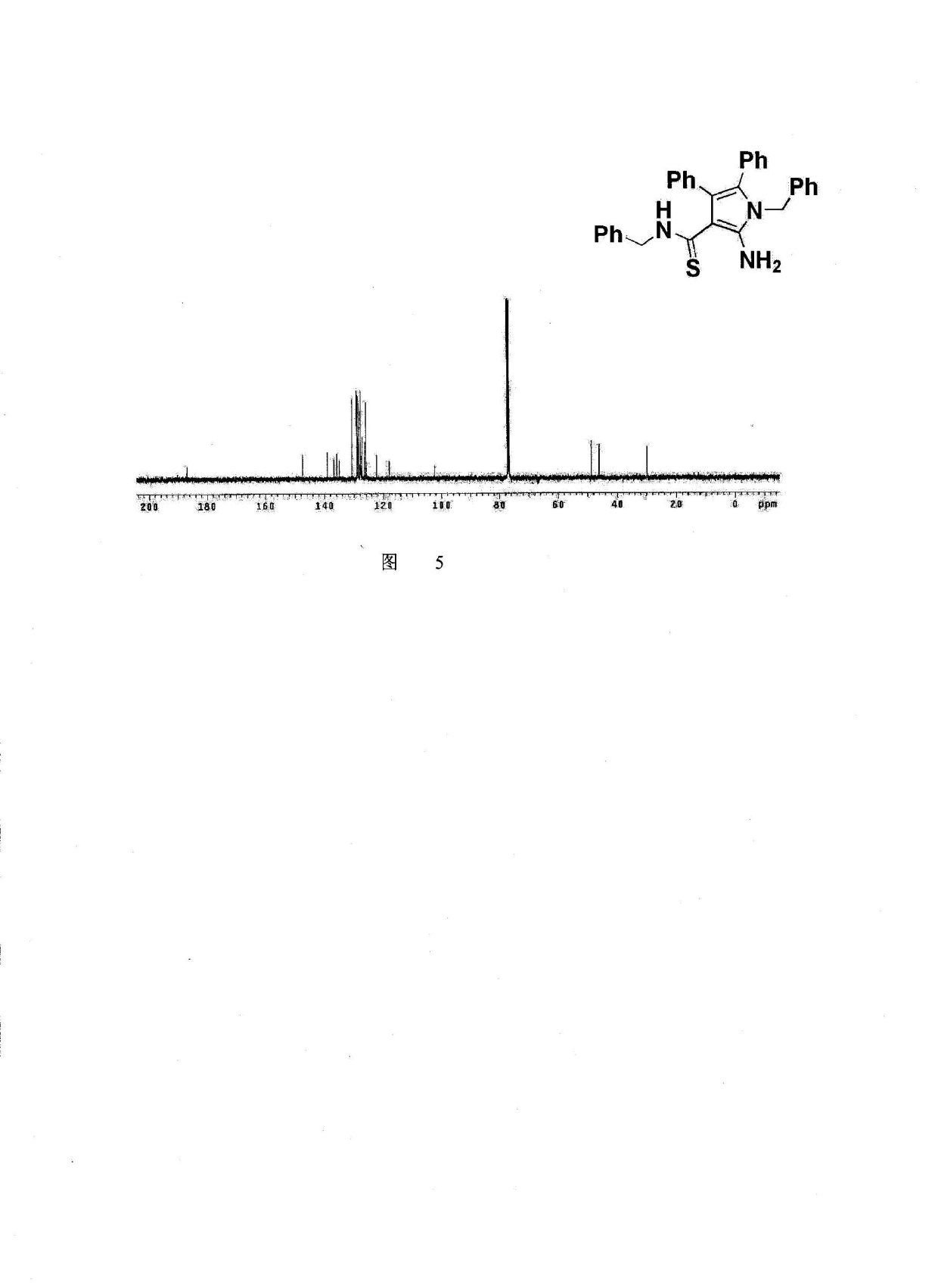

[0040] Spectral analysis data 2c :

[0041] 1 H-NMR (500 MHz, CDCl 3 ) δ 2.73 (s, 3H), 3.90 (s, 2H), 4.77 (d, J = 4.5 Hz, 2H), 5.00 (s, 2H), 6.88 (d, J = 7.0 Hz, 2H), 7.01-7.05 (m, 7H), 7.31 (d, J = 7.5 Hz, 2H), 7.42-7.47 (m, 8H); 13 C-NMR (CDCl 3 , 125 MHz) δ 11.84, 29.49, 47.28, 50.43, 115.27, 115.44, 120.41, 122.67, 125.56, 126.88, 127.04, 127.41, 127.65, 128.11, 128.63, 128.88, 128.91, 129.17, 129.23, 129.95, 133.56, 134.69, 134.71 , 134.90, 136.16, 136.87, 160.48, 162.43, 193.16; HRMS (ESI) m / z calculated for C 33 h 30 FN 2 S [M+1] + : 505.2114 found: 505.2079.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com