Method for preparing 1,6-hexanediol diacrylate

A technology of hexanediol diacrylate and hexanediol, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of poor polymerization inhibition effect and difficult removal, and achieve the appearance Excellent, easy to clean, easy to separate and recover the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

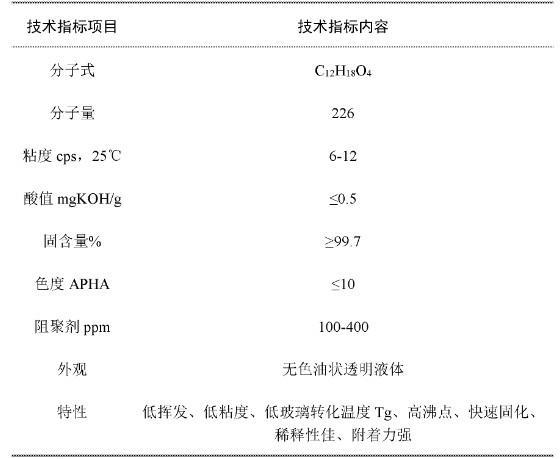

Image

Examples

Embodiment Construction

[0028] The preparation of 1,6-hexanediol diacrylate described in the present invention will be described in detail with examples below.

[0029] In this embodiment, a 250 mL three-necked flask is used as a reaction kettle in the embodiment of the present invention, and the reaction kettle is equipped with a thermometer, a stirring paddle, a water separator and a spherical condenser.

[0030] First, 47.28 g of 1,6-hexanediol, 3.12 g of hydrogen-type macroporous cation exchange resin, 5.4 g of sodium bicarbonate, acetic acid Copper 3.40 g, copper chloride 1.12 g, cyclohexane 170 mL, heated and stirred to make them fully mixed.

[0031] Heat the three-neck flask to raise the temperature to 55°C and maintain this temperature for 20 minutes. At the same time, add 70 mL of acrylic acid dropwise with a dropping funnel. After the addition of acrylic acid is completed, continue to heat up until the system is in a reflux state. At this time, the system temperature is 80 ~95°C, reflux f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| color hue | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com