Alumina spinel brick and its preparation method

A technology of aluminum spinel and fused spinel, applied in the field of refractory materials, can solve problems affecting the operation quality and life of equipment lining, secondary pollution of refractory material structure, brick composition and mineral phase change, etc., to achieve good results Thermal shock resistance, high refractoriness, low spalling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

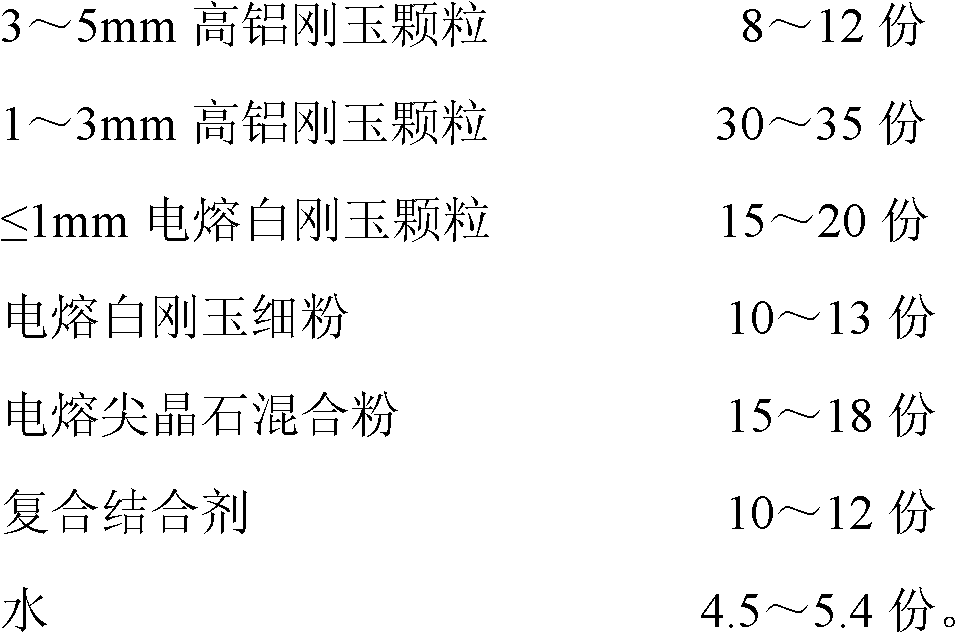

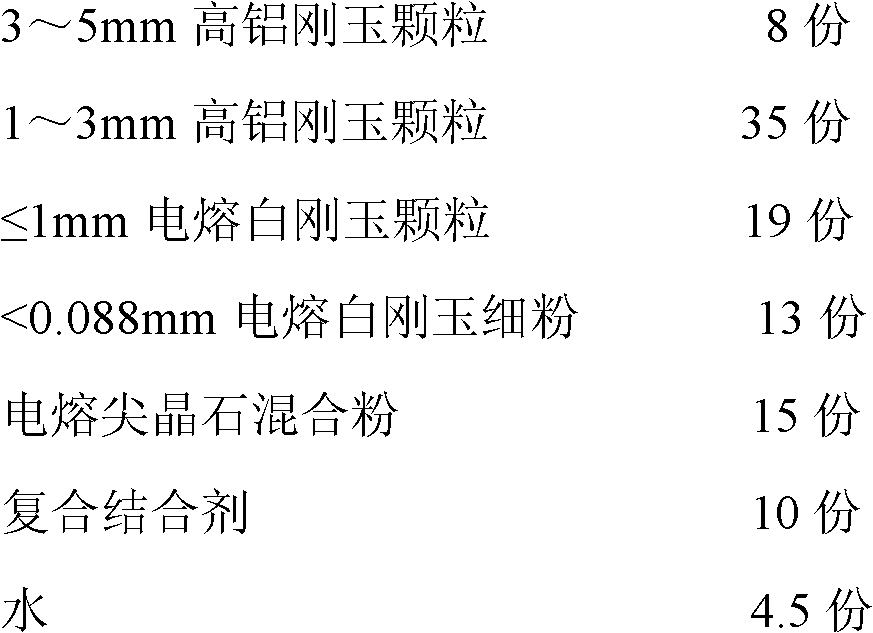

[0034] Get the following components in parts by weight:

[0035]

[0036] Wherein, the preparation method comprises the following steps:

[0037] (a) Premixing 13 parts of fused white corundum fine powder <0.088mm, 15 parts of fused spinel mixed powder and 10 parts of composite binder;

[0038] (b) 8 parts of high-alumina corundum particles of 3-5 mm, 35 parts of high-alumina corundum particles of 1-3 mm, 19 parts of fused white corundum particles of ≤1 mm, 4.5 parts of water and the pre-mixed materials in step (a) mixing;

[0039] (c) Send the mixed material in step (b) into a 4000KN friction brick press for pressing and forming, and the bulk density of the semi-finished product is 3.0-3.05g / cm -3 ;

[0040] (d) baking the adobe formed in step (c) at 60° C. for 48 hours until the residual moisture of the adobe is below 2%;

[0041] (e) Calcining the adobe obtained in step (d) at 1550-1580° C. for 5 hours to obtain the desired finished aluminum spinel brick.

[0042] W...

Embodiment 2

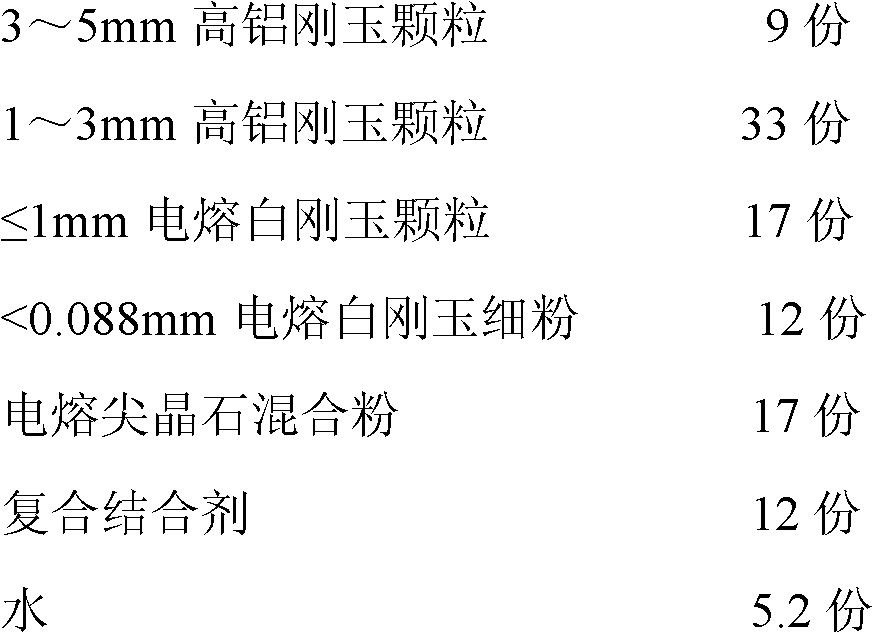

[0045] Get the following components in parts by weight:

[0046]

[0047] Wherein, the preparation method comprises the following steps:

[0048] (a) Premixing 12 parts of fused white corundum fine powder <0.088mm, 17 parts of fused spinel mixed powder and 12 parts of composite binder;

[0049] (b) 9 parts of high-alumina corundum particles of 3-5 mm, 33 parts of high-alumina corundum particles of 1-3 mm, 17 parts of fused white corundum particles of ≤1 mm, 5.2 parts of water and the pre-mixed materials in step (a) mixing;

[0050] (c) Send the mixed material in step (b) into a 4000KN friction brick press for pressing and forming, and the bulk density of the semi-finished product is 3.05~3.1g / cm -3 ;

[0051] (d) baking the adobe formed in step (c) at 80° C. for 40 hours until the residual moisture of the adobe is below 2%;

[0052] (e) Calcining the adobe obtained in step (d) at 1550-1580° C. for 4.5 hours to obtain the desired finished aluminum spinel brick.

[0053]...

Embodiment 3

[0056] Get the following components in parts by weight:

[0057]

[0058] Wherein, the preparation method comprises the following steps:

[0059] (a) Premix 11 parts of fused white corundum fine powder <0.088mm, 16 parts of fused spinel mixed powder and 11 parts of composite binder;

[0060] (b) 12 parts of high-alumina corundum particles of 3-5 mm, 30 parts of high-alumina corundum particles of 1-3 mm, 20 parts of fused white corundum particles of ≤1 mm, 5 parts of water and the pre-mixed materials in step (a) mixing;

[0061](c) Send the mixed material in step (b) into a 4000KN friction brick press for pressing and forming, and the bulk density of the semi-finished product is 3.05~3.1g / cm -3 ;

[0062] (d) baking the adobe formed in step (c) at 90° C. for 36 hours until the residual moisture of the adobe is below 2%;

[0063] (e) Calcining the adobe obtained in step (d) at 1550-1580° C. for 4.5 hours to obtain the desired finished aluminum spinel brick.

[0064] Wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com