Preparation method of supported type denitration catalyst

A denitration catalyst, a supported technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of high preparation energy consumption, poor low temperature activity, narrow denitration activity temperature window, etc., to reduce poisoning. effect, reducing the preparation cost, and widening the denitration temperature window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

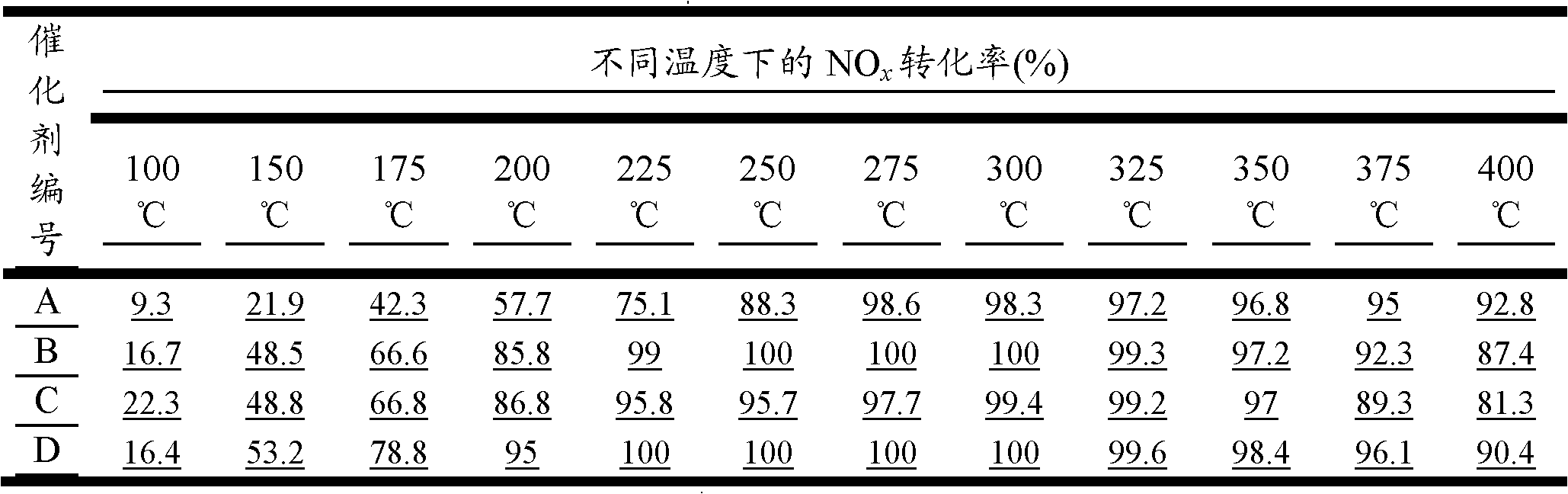

Embodiment 1

[0021] Dissolve ferric nitrate and cerium nitrate in water to obtain a mixed solution, stir the solution uniformly with magnetic force, add a certain amount of titanium dioxide carrier to the solution, and control Fe: Ce: TiO 2 The molar ratio of the solution is 19:1:100. Firstly, the magnetic stirring is continued for 1 hour at room temperature for impregnation, and then an excessive amount of ammonia water is slowly added dropwise to the mixed solution for deposition until the pH value of the mixed solution is 9-10, and the deposition is complete and After filtering and washing, the filter cake was placed in a microwave test bench and microwaved at a power of 210W for 10 minutes. After the microwave treatment, the sample was dried in a drying box at 105°C, and finally passed through a muffle furnace and 400°C in air. The catalyst was prepared by calcination and activation for 5h. Grind and sieve the prepared catalyst, take 40-60 mesh for later use, and become catalyst A.

Embodiment 2

[0023] The procedure is the same as in Example 1, other conditions remain unchanged, and the molar ratio of Fe / Ce is changed to 15:5 to prepare catalyst B.

Embodiment 3

[0025] The procedure was the same as in Example 1, other conditions remained unchanged, and the molar ratio of Fe / Ce was changed to 12.5:7.5 to prepare catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com