Separating flexible speed increasing device based on inner-curve hydraulic motor

A technology of hydraulic motor and speed-increasing device, which is applied in the directions of fluid pressure actuating device, transmission of mechanical power, fluid pressure actuating system components, etc., can solve the problem that the speed change mechanism cannot adapt to the demand of wind power generation, and reduce the mass of the tower. , reduce production costs, the effect of small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

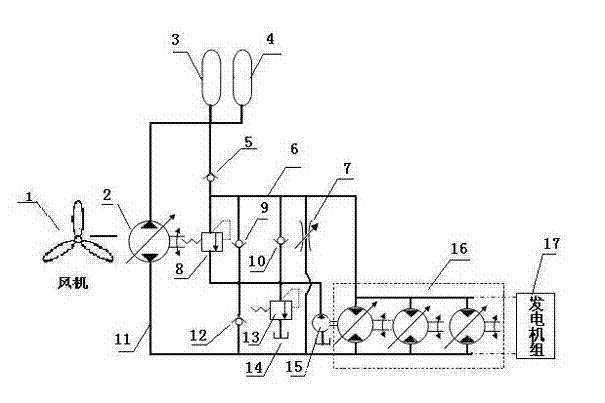

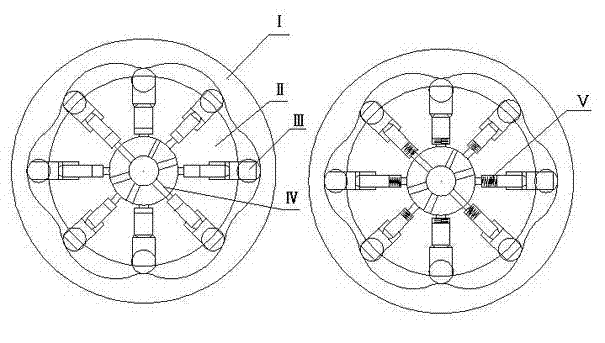

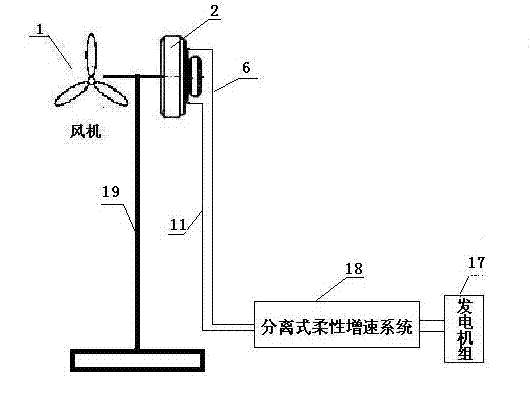

[0017] A separate flexible speed increasing device based on an inner curve hydraulic motor. The inner curve hydraulic motor 2 includes a stator I, a rotor II, a plunger assembly III, a distribution shaft IV and a return spring V. The return spring V is arranged on the plunger assembly Between Ⅲ and the oil outlet. The inner curve hydraulic motor 2 is installed on the top of the tower 19, and the two ends of the inner curve hydraulic motor 2 are respectively connected to the low pressure hydraulic pipeline 11 and the high pressure hydraulic pipeline 6 for pumping the low pressure end hydraulic oil to the high pressure end.

[0018] The separated flexible speed increasing system 18 includes a first high-pressure end accumulator 3, a second high-pressure end accumulator 4, a high-pressure hydraulic pipeline 6, a first one-way valve 5, a second one-way valve 9, and a third one-way valve 10. The fourth check valve 12, the first relief valve 8, the second relief valve 13, the throttle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com