Rubber composition for tire and pneumatic tire

A rubber composition and a technology for pneumatic tires, which are applied in the fields of rubber compositions for tires and pneumatic tires, can solve the problem of insufficient improvement in tear strength and fatigue resistance, undocumented porous inorganic fillers or layered viscosity mineral shapes, etc. problem, to achieve the effect of reducing rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

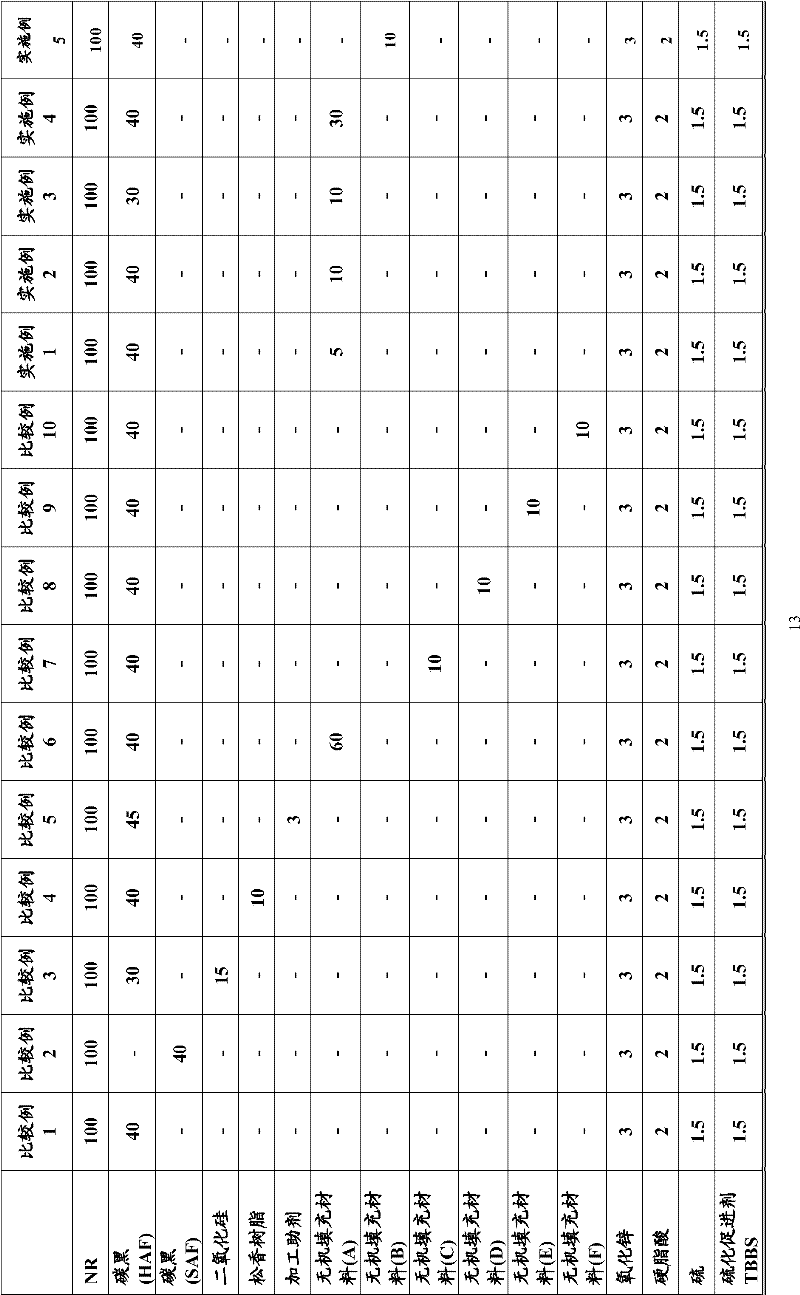

[0021] The rubber composition for tires of the present invention contains at least a rubber component and an inorganic filler. In the present invention, it is preferable to contain a diene rubber as a rubber component.

[0022] Examples of diene rubber include natural rubber (NR), polyisoprene rubber (IR), styrene-butadiene rubber (SBR), polybutadiene rubber (BR), Diene rubbers such as butadiene rubber (SPB), chloroprene rubber (CR), and nitrile rubber (NBR) can be used alone or in combination of two or more. As these exemplified diene rubbers, terminal-modified substances (for example, terminal-modified BR or terminal-modified SBR, etc.), or substances modified to impart desired characteristics (such as modified NR). In addition, for polybutadiene rubber (BR), in addition to rubber synthesized using cobalt (Co) catalyst, neodymium (Nd) catalyst, nickel (Ni) catalyst, titanium (Ti) catalyst, lithium (Li) catalyst, it is also possible to use Rubber synthesized by the polymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com