Array substrate and manufacturing method and display device thereof

A technology of an array substrate and a manufacturing method, which is applied to the field of an array substrate and a manufacturing method thereof and a display device, can solve the problems of difference, influence on display effect, common electrode voltage change, etc., so as to avoid crosstalk phenomenon, eliminate coupling effect, and reduce resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

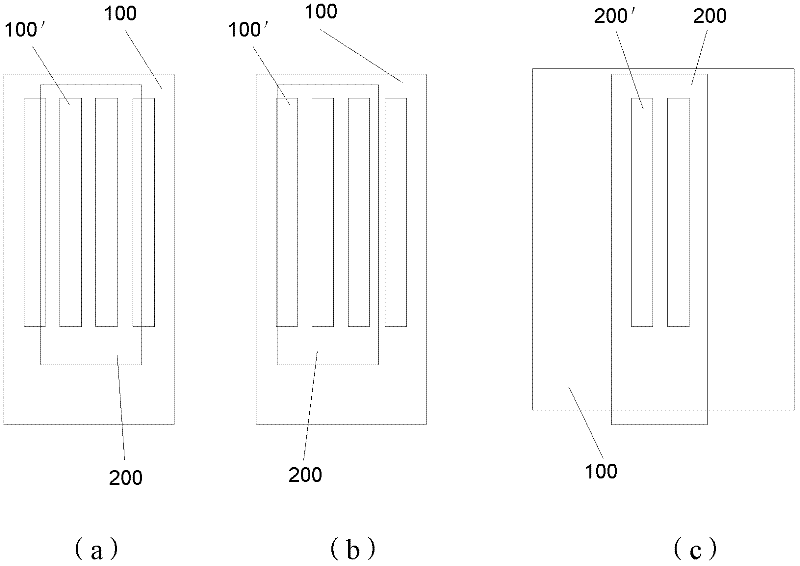

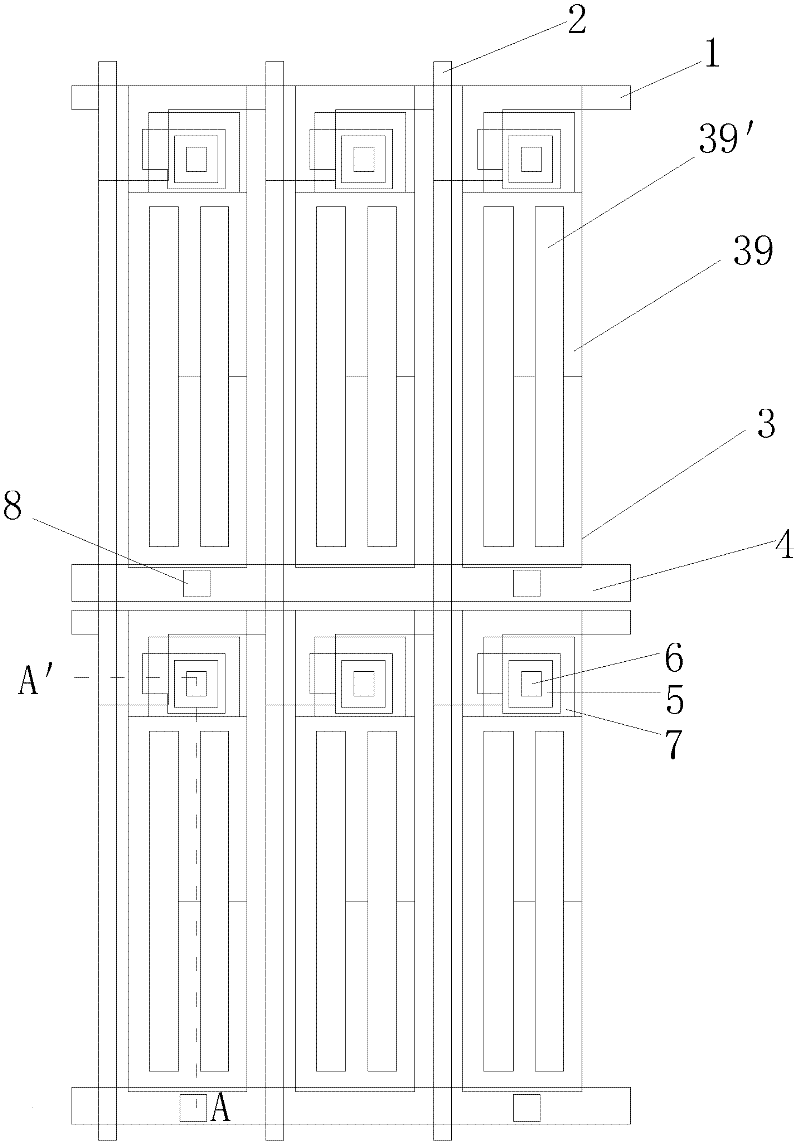

[0045] The ADS type array substrate of this embodiment, such as figure 2As shown, it includes: gate line 1, data line 2 and several thin film transistor pixel structures 3 between gate line 1 and data line 2 (each thin film transistor pixel structure corresponds to a pixel unit), each thin film transistor pixel structure 3 Including a thin film transistor and a display area, wherein the thin film transistor includes a gate, a gate insulating layer, an active layer, a source and a drain ( figure 2 not shown), the display area refers to the area used for display outside the thin film transistor (corresponding to the area where the pixel electrode is located), including the pixel electrode 39 and the common electrode ( figure 2 not shown), the common electrode is a block-shaped common electrode connected as a whole on the entire array substrate. The array substrate also includes at least one common electrode line 4 connected to the common electrode of the thin film transistor...

Embodiment 2

[0061] Since a number of common electrode lines 4 are added to the array substrate structure of Example 1, if the traditional ADS method is used, the common electrode lines 4 need to have a certain distance from the gate lines 1, which will cause them to block the normal light-emitting area and affect the aperture ratio. In order to increase the aperture ratio, the array substrate of this embodiment is arranged in such a way that TFTs face each other. Such as Figure 4 Shown (the cross-sectional view of each thin film transistor pixel structure and image 3 similar), among the several thin film transistor pixel structures 3 divided by the gate line 1, the thin film transistor regions of two adjacent rows of thin film transistor pixel structures 3 (that is, two adjacent rows of pixel units) are arranged adjacently, and the adjacent two rows of thin film transistor pixel structures The respective display areas of 3 are respectively arranged adjacent to the display areas of the ...

Embodiment 3

[0071] This embodiment provides a display device including the array substrate in Embodiment 1 or 2. The display device can be: liquid crystal panel, electronic paper, OLED panel, liquid crystal TV, liquid crystal display, digital photo frame, mobile phone, tablet computer, etc. Any product or part that has a display function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com