Preparation method of low-temperature polycrystalline silicon film and low-temperature polycrystalline silicon film

A low-temperature polysilicon and polysilicon growth technology, used in transistors, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as affecting the current characteristics of polysilicon thin film transistors, and achieve the effect of improving current characteristics and low surface roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this embodiment, the following steps are used to prepare a low-temperature polysilicon thin film:

[0042] (1) Forming a buffer layer on the substrate: the substrate 101 is a glass substrate, and after the glass substrate is pre-cleaned, a double-layer structure SiN is deposited by plasma-enhanced chemical vapor deposition (PECVD) x / SiO 2 The thin film is used as an insulating buffer layer, first depositing a 100nm silicon nitride layer 102, and then depositing a 200nm silicon dioxide layer 103;

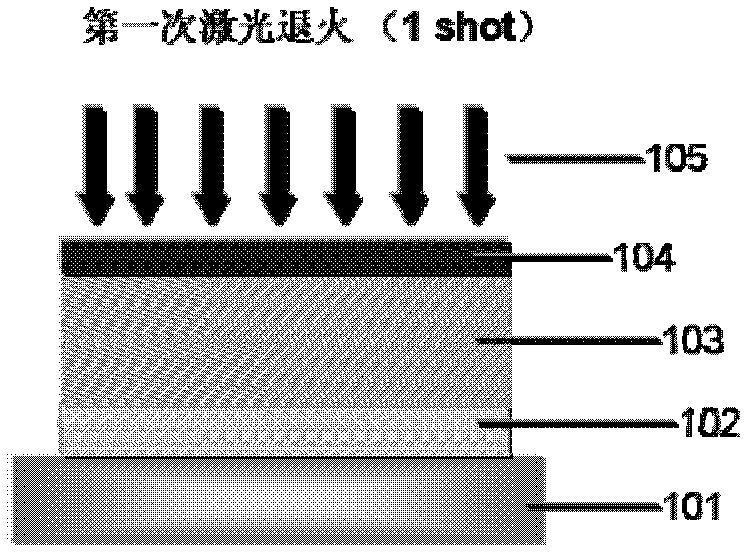

[0043] (2) Forming an amorphous silicon layer of 30-100 nm on the insulating buffer layer obtained in step (1): depositing an amorphous silicon layer 104 of 60 nm;

[0044] (3) Perform high-temperature treatment on the amorphous silicon layer obtained in step (2): at a temperature of 450° C., perform high-temperature treatment on the amorphous silicon layer 104 for 2 hours;

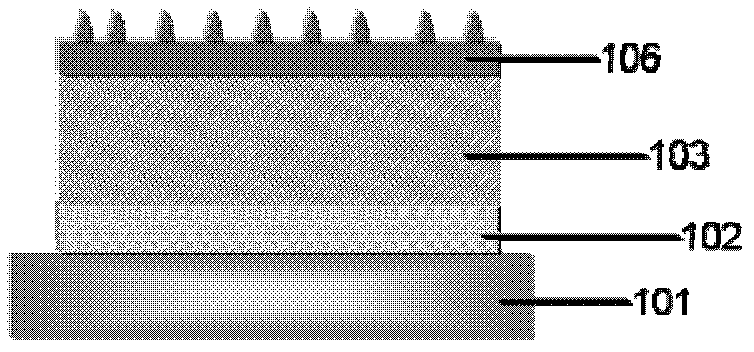

[0045] (4) The first laser annealing treatment is carried out on the amorphous silicon layer, so...

Embodiment 2

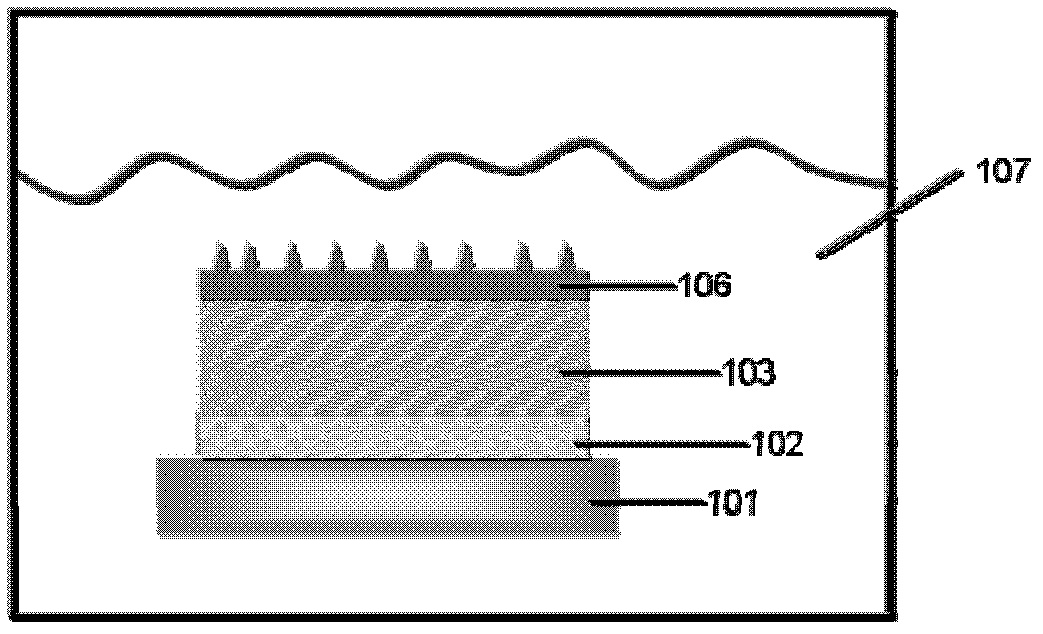

[0050] The main method steps are the same as in Example 1, except that the etching solution 107 in step (4) is cleaned with a concentration of 1 wt% dichromic acid solution, and the etching time is 60s; step (6) adopts 39 shots (shooting times) Perform the second annealing treatment 109, select the laser linear beam width to be 400 μm, the laser pulse frequency to be 300 Hz, and the laser energy density to be 400 mJ / cm 2 , the scanning speed is 2mm / s, and the pulse width is 25 nanoseconds. The surface of the obtained polysilicon film was detected by an atomic force microscope (AFM), and the highest protrusion was only about 20 nm.

[0051] Figure 7 It is a schematic cross-sectional view of a polysilicon film 111 obtained in the prior art. It can be seen that the protrusions at the grain boundaries are very obvious, and are generally substances with high resistance (the combination of silicon-silicon valence bonds and partial oxides that have a distorted crystal lattice). , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com