Blind via filling plating method using different current parameter combinations

A technology of current parameters and blind holes, which is applied in the direction of the electrical connection of printed components, can solve the problems of unsatisfactory hole filling effect, long time for filling blind holes, low efficiency, etc., shorten the time required for electroplating, and achieve the desired effect of electroplating. It takes a short time to achieve the effect of interconnection and conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

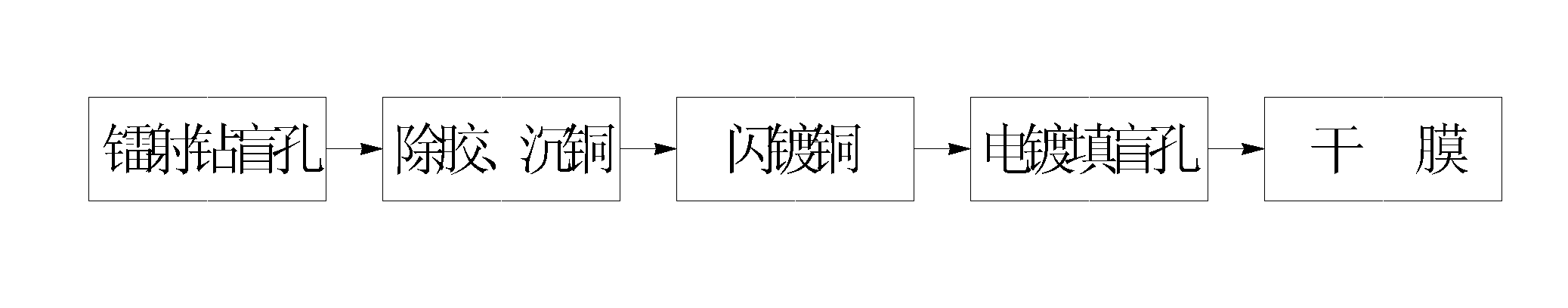

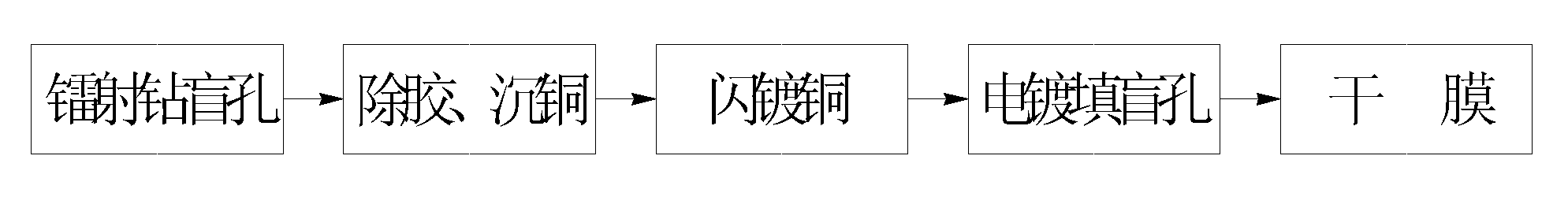

[0016] refer to figure 1 Shown, a kind of electroplating blind hole filling method that adopts different current parameter combinations of the present invention comprises the following steps: (1) carry out deglue, electroless copper and copper flash plating operation to circuit board outer layer; (2) ) Carry out electroplating for blind hole filling on the second outer layer of the circuit board; (3) Carry out dry film operation to the circuit board; wherein step (2) is specifically: first adjust the electroplating potion to high copper sulfate and low sulfuric acid, specifically by adding pentahydrate Copper sulfate or copper oxide powder, increase the concentration of copper ions, so that the mass ratio of sulfuric acid to copper ions in the electroplating potion is less than 12:1; then use different current densities for electroplating in three sections: the first section uses a current density of 1.5-2.5 amps / dm2 for electroplating, the preferred current density is 2 amps / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com