Preparation method of ceramic coloration toner for color laser printer

A laser printer and toner technology, applied in optics, electrical recording, instruments, etc., can solve the problems of high cost, complicated process, low efficiency, etc., achieve the effect of vivid color reproduction, overcome high cost, and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with specific embodiments.

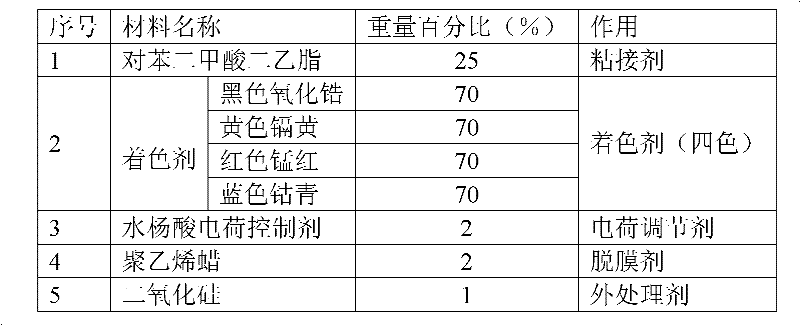

[0020] The coloring principle of the embodiment of the present invention is consistent with that of a color laser printer, the difference is that the printing medium toner is replaced with ceramic coloring toner. Since the developing colorants used in laser printers are all organic colorants, the direct use of such colorants cannot adapt to high-temperature sintering of ceramics. Referring to Table 1, inorganic high-temperature colorants and a small amount of organic materials (red: manganese red, yellow: cadmium yellow, cyan: cobalt blue, black: zirconia) are used in the embodiment of the present invention. Inorganic coloring pigments are fused with a small amount of organic polymer materials to form a developing material for laser printers. After electrostatic development of laser printers, various coloring pigments are colored on a plastic film to form colorful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com