Vehicle chassis height sensor

A chassis height and sensor technology, which is applied in the direction of instruments, measuring devices, and electrical devices, can solve the problems of high requirements for magnetic conductor materials and high assembly requirements, and achieve the effects of simple assembly process, good environment and reduced manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

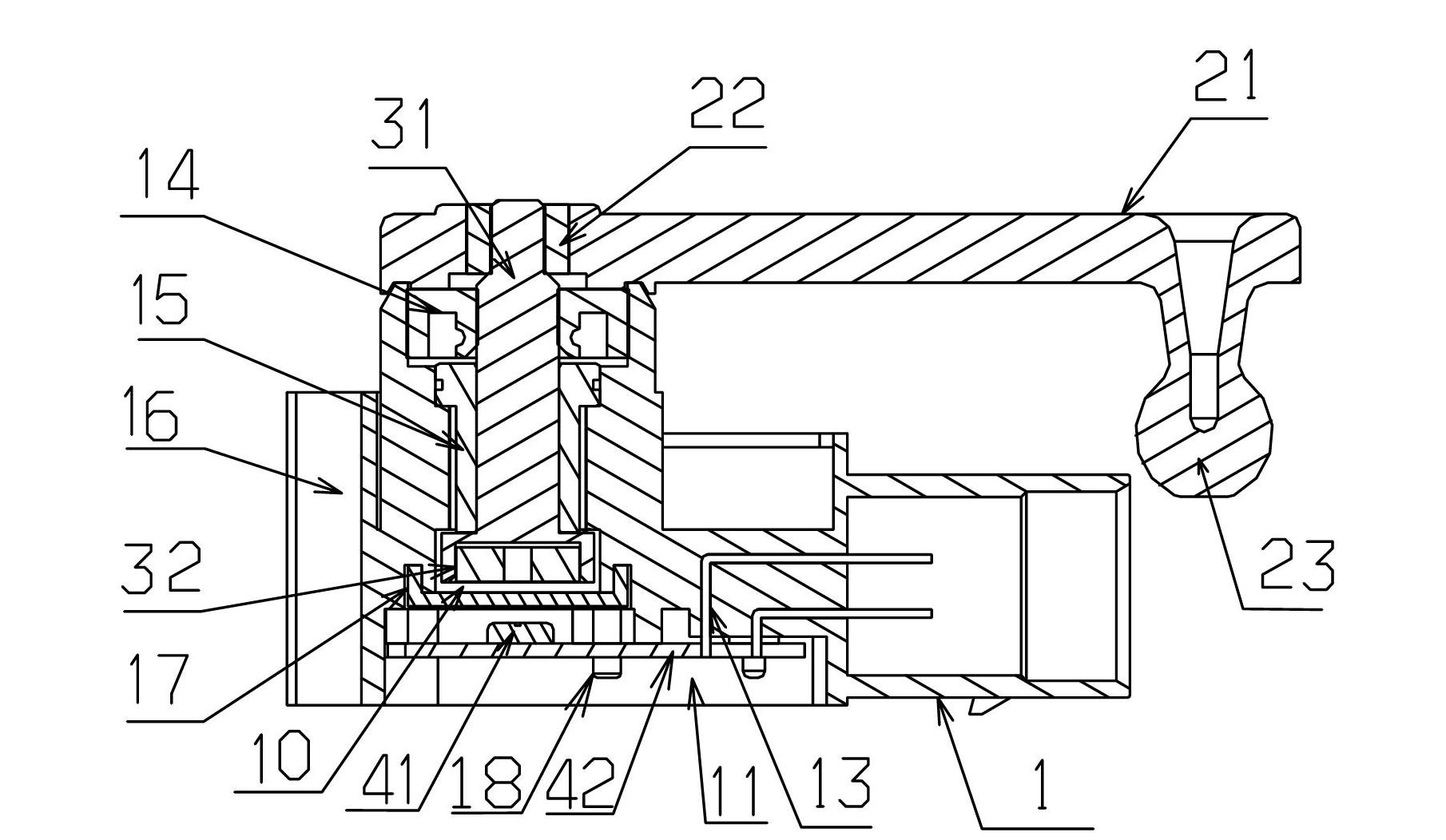

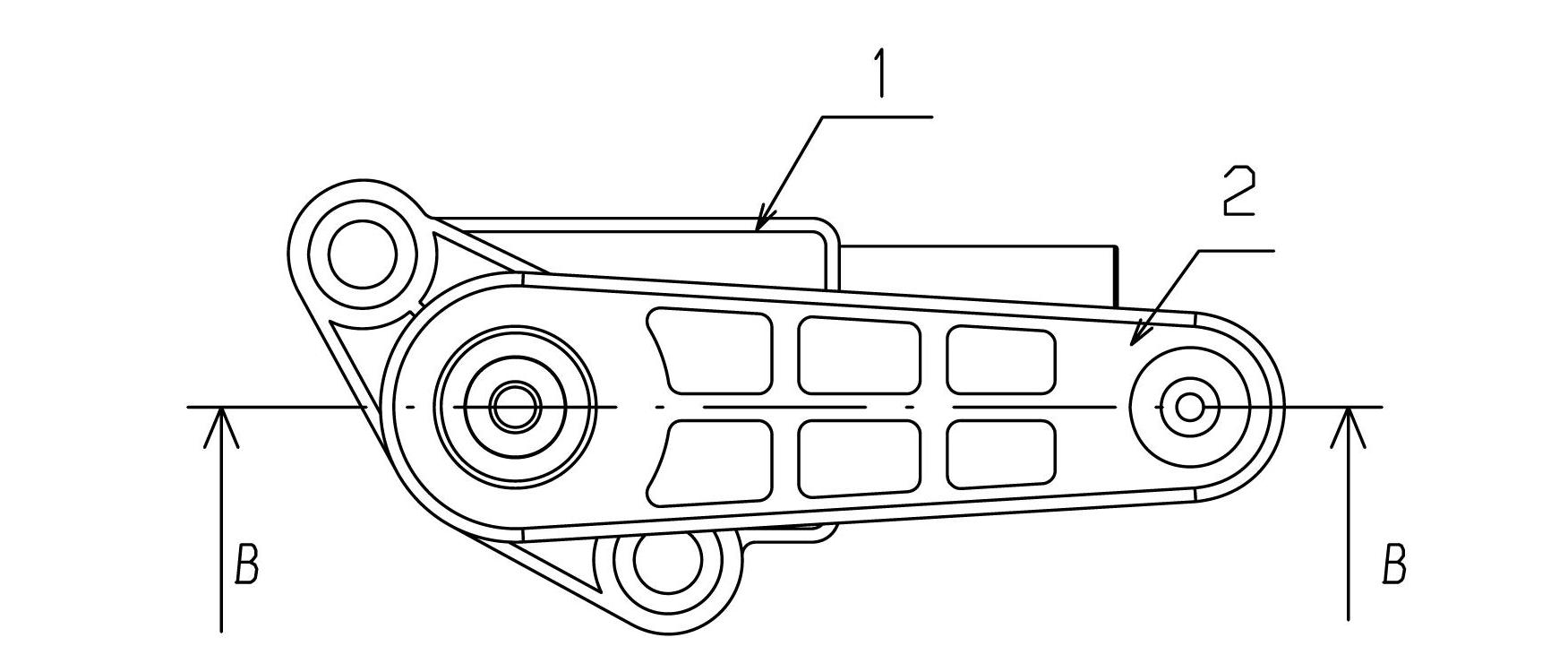

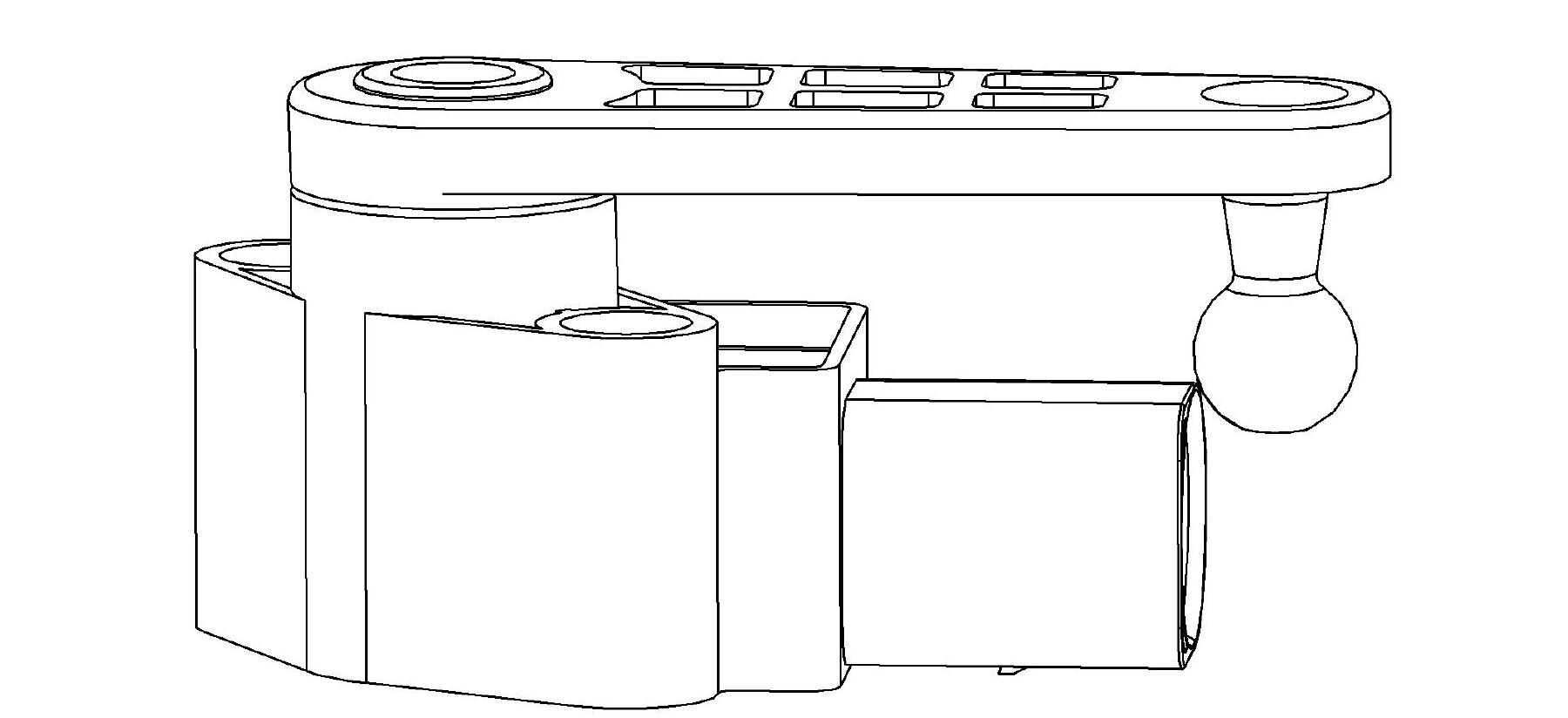

[0031] The structure of the vehicle chassis height sensor of the present invention is as figure 1 As shown, it includes a housing 1, a swing arm unit 2, a rotating unit 3 and a Hall sensor unit 4. The housing 1 is integrally injection molded, and a bearing 15 and a set of pins are embedded in the housing 1 by injection molding. 13 and two embedded nuts 16, the vehicle chassis height sensor is fixedly connected to the vehicle body of the vehicle by two embedded nuts 16. The rotating unit 3 includes a rotating shaft 31 and a magnetic steel 32. The upper end of the rotating shaft 31 is connected to the chassis of the vehicle through the swing arm unit 2. The magnetic steel 32 is fixedly connected to the lower end of the rotating shaft 31. The rotating shaft 31 passes through the bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com