Novel connection mode for steel mesh skeleton plastic compound pipelines

A technology of composite pipes and connection methods, which is applied in the direction of pipe connection layout, pipe/pipe joints/pipe fittings, mechanical equipment, etc. The effect of hard to find power supply, good sealing performance and firm pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

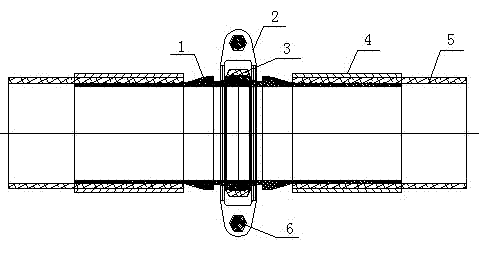

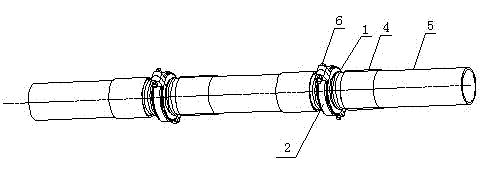

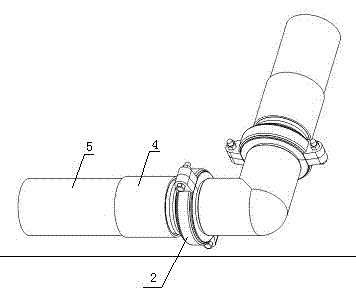

[0026] A new type of connection method for plastic composite pipelines with steel mesh skeletons. The inner and outer outer iron castings and flexible quick connectors are used as the pipeline connectors. Push one end of the inner sleeve iron casting 1 into the port of the pipe 5, then put the pipe end with the inner and outer sleeve iron castings in the shrinking machine to squeeze and seal the mouth, and the other end of the inner sleeve iron casting 1 protrudes from the Outside the port of the pipe 5, use the flexible quick joint 2 to fasten and connect the two inner sleeve cast iron parts 1 protruding from the pipe port. A rubber sealing ring 3 is installed inside the flexible quick joint, and the flexible joint is contracted by the screw 6 and the nut. The quick connector squeezes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com