Full-closed type double-ball type interlocking separation valve

A fully enclosed, isolating valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of closed control isolating valve technology application restriction, difficult to optimize process pipeline design, occupying large pipeline space and other problems. Optimize process pipeline design, compact structure, and reduce the effect of occupying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

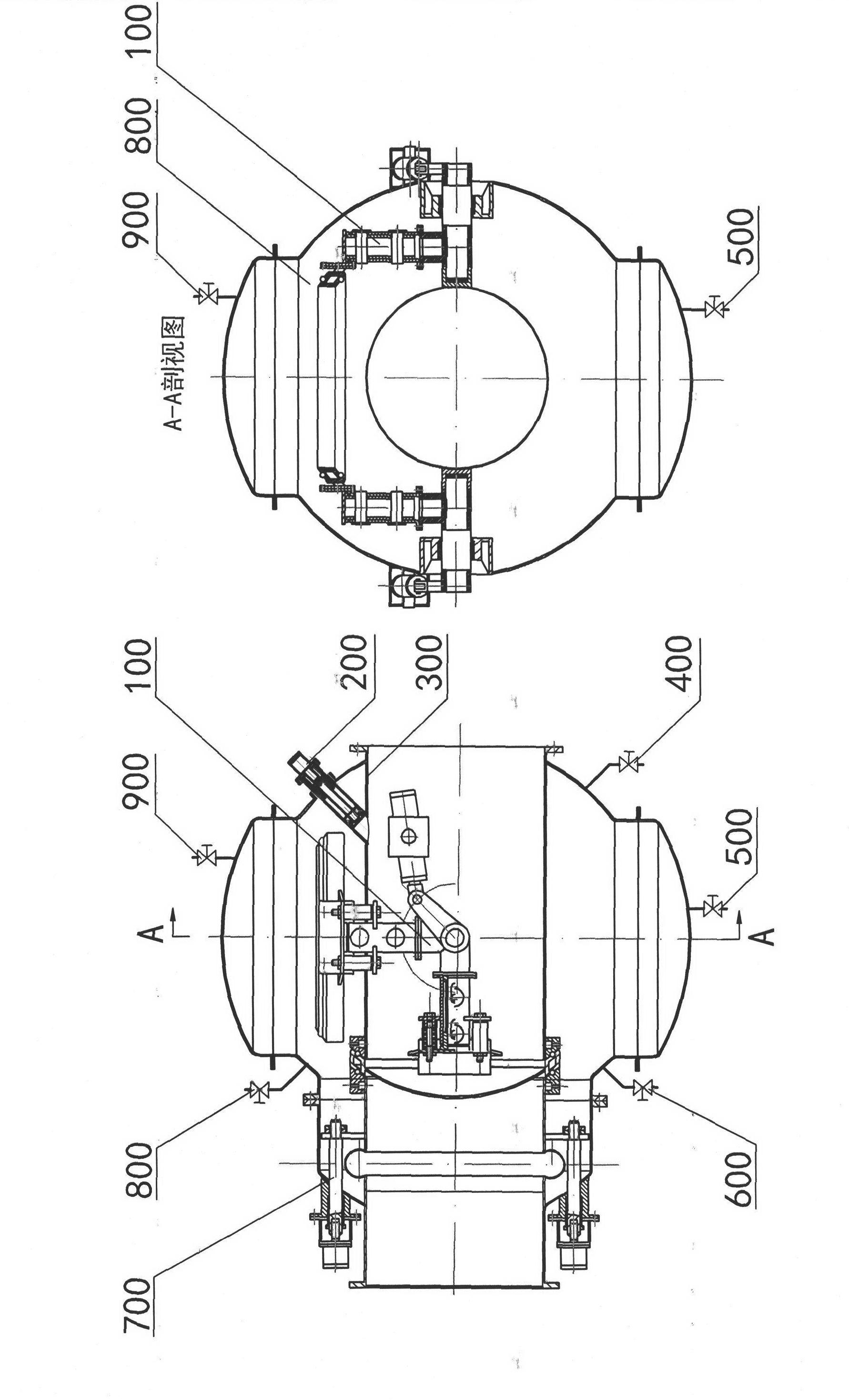

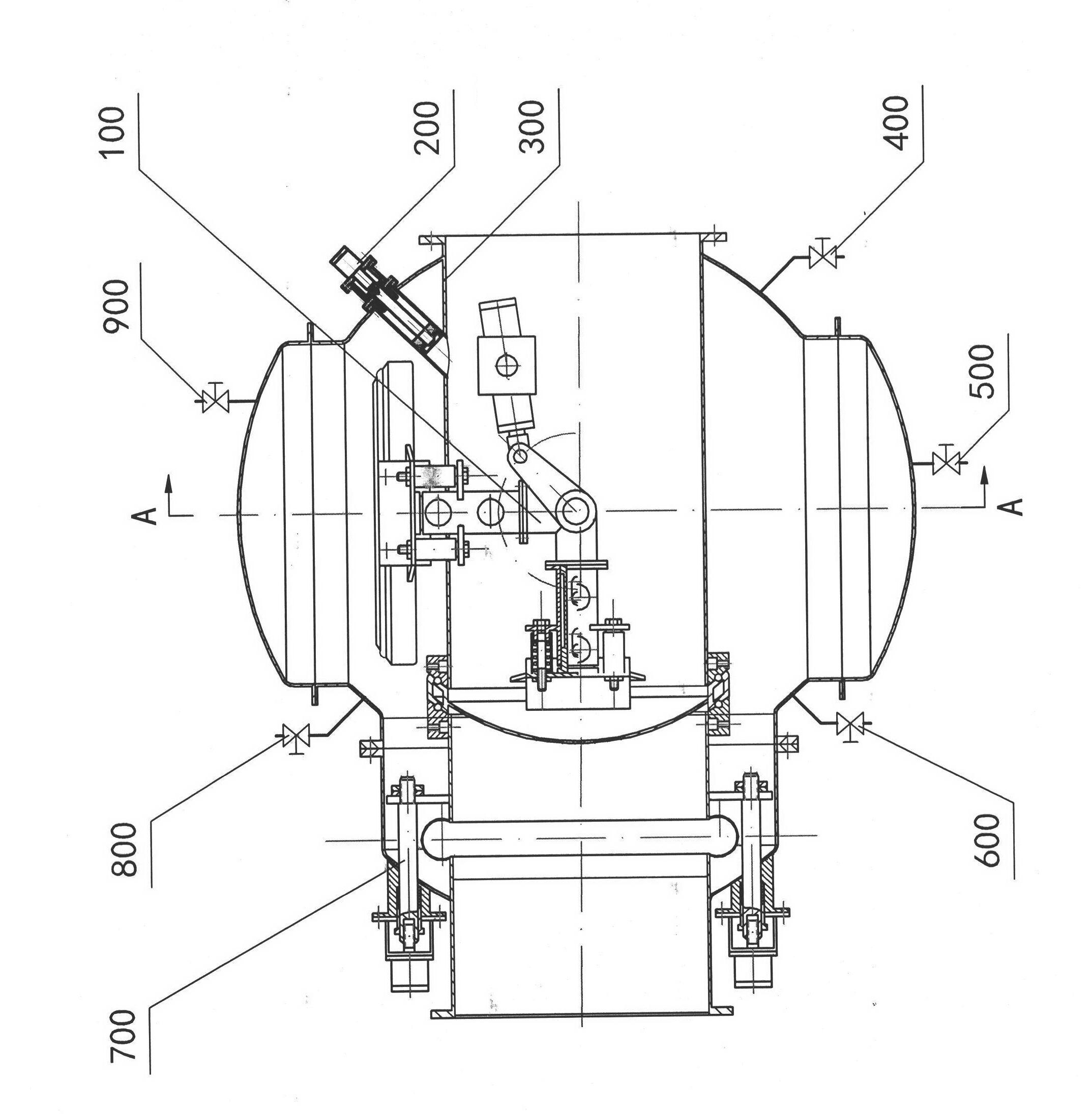

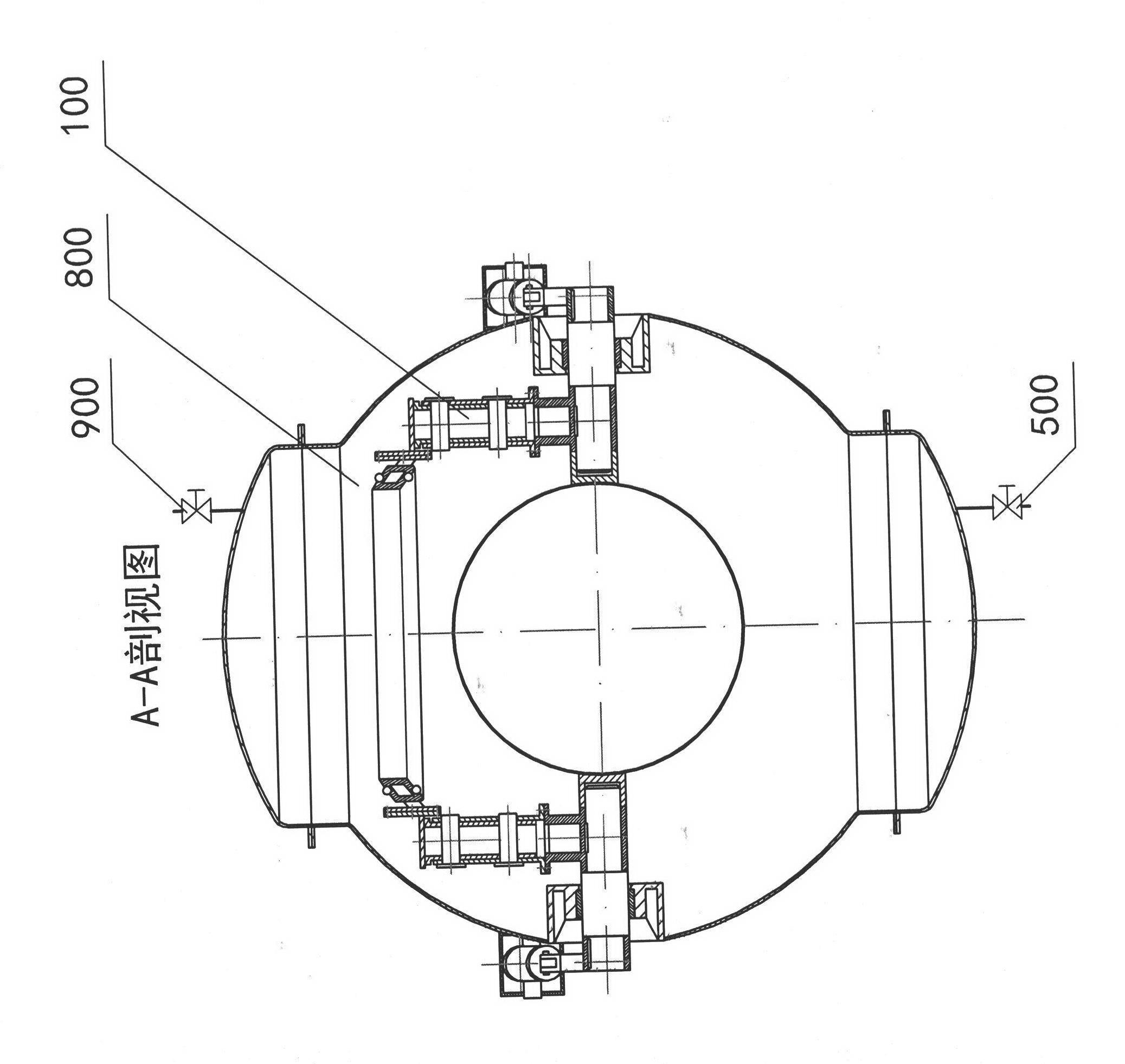

[0029] The fully enclosed double-ball interlocking partition valve of the present invention is a full-pass design, which is characterized in that it adopts a double-ball valve plate, which rotates synchronously along the ball track, floats independently, and has no frictional opening and closing conversion function. type valve plate turnover mechanism (100), and interlocking pressure equalizing mechanism (200), and spherical valve body (300), and replacement device (400), and sewage discharge device (500), and cooling system (600), and more The spherical valve plate clamping mechanism (700) with point-to-position synchronous expansion and contraction function, together with the purging device (800) and the release device (900) constitute the isolation valve equipment. Its double-spherical valve plate turnover mechanism (100) consists of a spherical crown type blind plate valve plate (101), a spherical crown type through-hole valve plate (102), a rotary lug device (103), and a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com