Durable fresh-maintained preservative primer

A technology of anti-corrosion primer and primer, which is applied in the direction of anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of large amount of metal elements, unprominent functions, weak weather resistance, etc., and achieve good adhesion and convenient construction , the tough effect of the paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

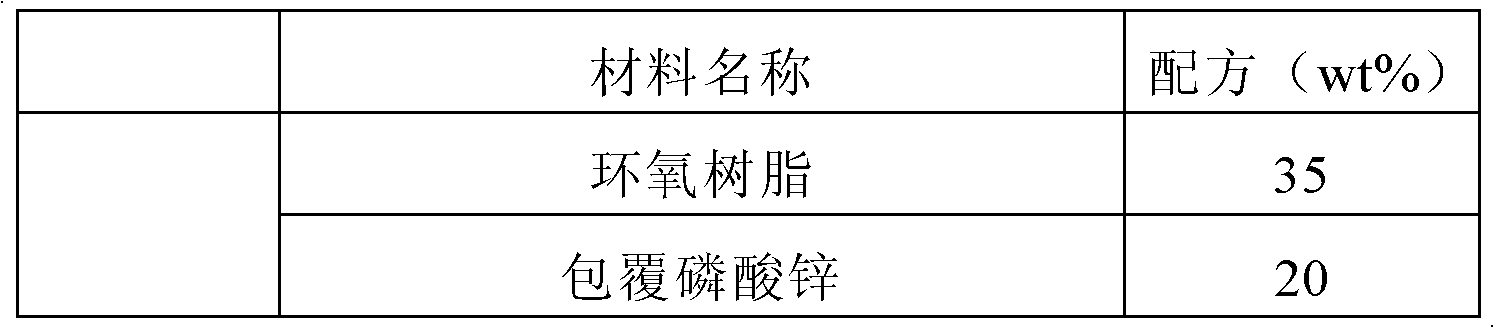

[0026] The formula of Jiubao new anti-corrosion primer is shown in Table 1.

[0027] Table 1

[0028]

[0029]

[0030] According to the formula in the above table, prepare component A and component B separately and then mix them evenly. The dosage of component B is 10wt% of that of component A, then mix evenly and apply in the product.

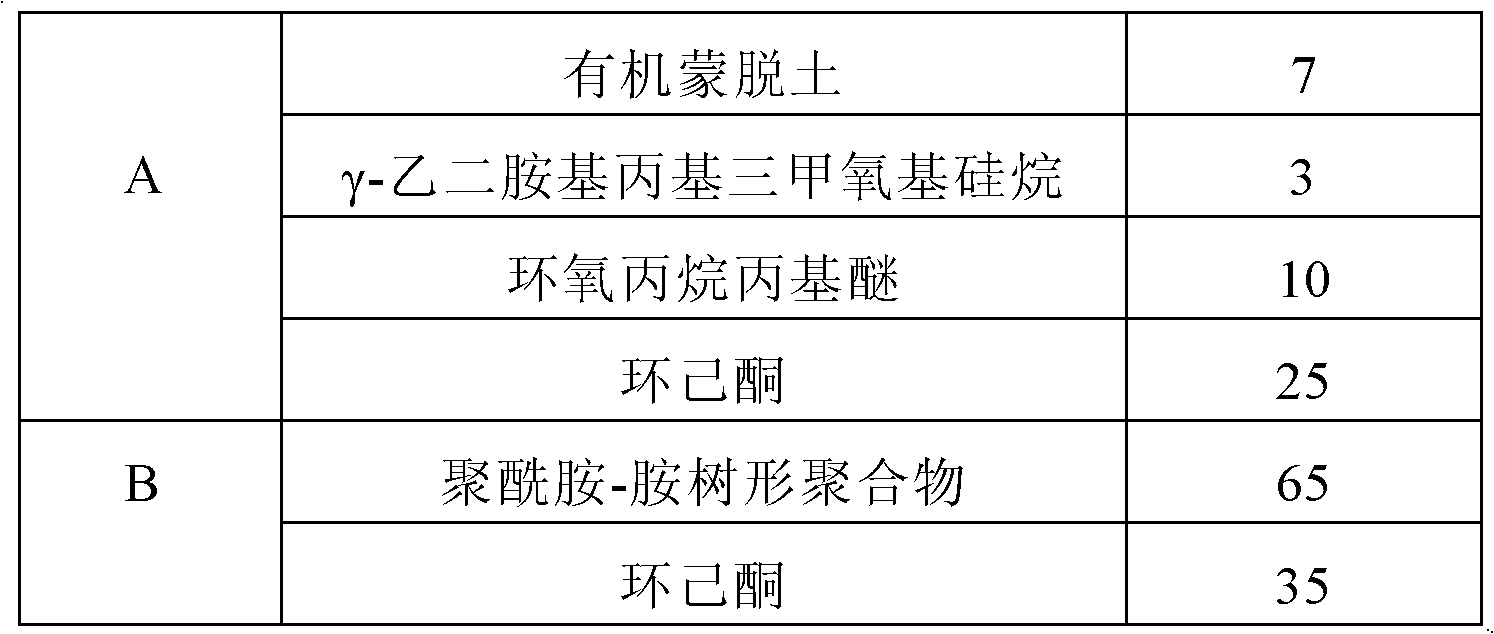

[0031] The following table is the salt spray performance comparison of embodiment 1 and epoxy zinc-rich primer:

[0032] Table 2 Example 1 and epoxy zinc-rich primer salt spray performance comparison

[0033]

[0034] Epoxy zinc-rich primer is used on the sandblasted steel plate, the average film thickness is about 80 μm, and the theoretical dosage is 380g, while Example 1 is used on the artificially derusted steel plate, the theoretical dosage is 238g, and the dry film thickness can also reach 80 μm.

Embodiment 2

[0036] The formula of Jiubao new anti-corrosion primer is shown in Table 3.

[0037] table 3

[0038]

[0039]

[0040] According to the formula in the above table, prepare component A and component B separately and then mix them uniformly. The dosage of component B is 5wt% of component A, then mix and evenly coat the product.

[0041] The following table is the salt spray performance comparison of embodiment 2 and epoxy zinc-rich primer:

[0042] Table 4 Example 2 and epoxy zinc-rich primer salt spray performance comparison

[0043]

[0044] Epoxy zinc-rich primer is used on the steel plate after sandblasting, the average film thickness is about 80 μm, and the theoretical dosage is 380g, while Example 2 is used on the artificially derusted steel plate, the theoretical dosage is 230g, and the dry film thickness can also reach 80 μm.

Embodiment 3

[0046] The formula of Jiubao new anti-corrosion primer is shown in Table 5.

[0047] table 5

[0048]

[0049] According to the formula in the above table, prepare component A and component B separately and then mix them evenly. The dosage of component B is 15wt% of that of component A, then mix evenly and apply it in the product.

[0050] The following table is the salt spray performance comparison of embodiment 3 and epoxy zinc-rich primer:

[0051] Table 6 Example 3 and epoxy zinc-rich primer salt spray performance comparison

[0052]

[0053] Epoxy zinc-rich primer is used on the sandblasted steel plate, the average film thickness is about 80 μm, and the theoretical dosage is 380g, while Example 3 is used on the artificially derusted steel plate, the theoretical dosage is 234g, and the dry film thickness can also reach 80 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com