Carving and molding process of leather

A molding process and leather technology, which is applied in the crafts and decorative arts for producing decorative surface effects, etc. It can solve the problems of high mold requirements, easy cracking and deformation of leather, high processing cost, etc., and achieve strong three-dimensional effect and low mold processing cost , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

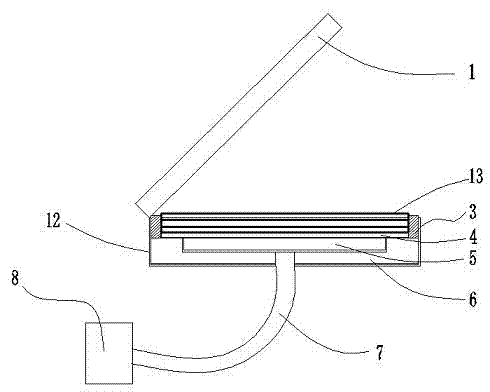

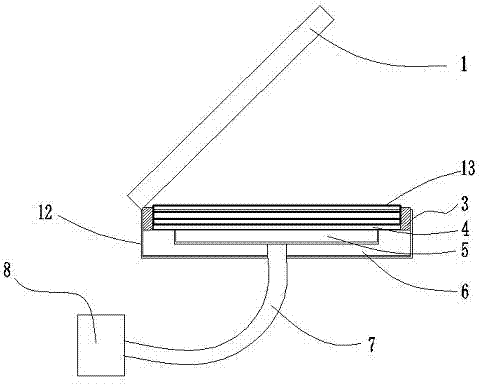

[0027] The vacuum suction device used in this embodiment is as figure 1 As shown, it includes a box body 12 with an upper cover 1. After the upper cover 1 and the box body 12 are closed, the whole body is sealed. A cavity is arranged in the box body 12, and a support plate with a vacuum hole is placed at the bottom of the cavity. 6. The support plate 6 is connected to the vacuum device 8 through the ventilation pipe 7, and a heating plate 5 for placing the blister mold 4 is fixed above the support plate 6, and a sealing ring 3 is arranged around the heating plate 5 on the support plate .

[0028] The leather engraving molding technique of the present invention is specifically as follows steps:

[0029] 1) Make the corresponding blister mold according to the selected three-dimensional figure or pattern 4;

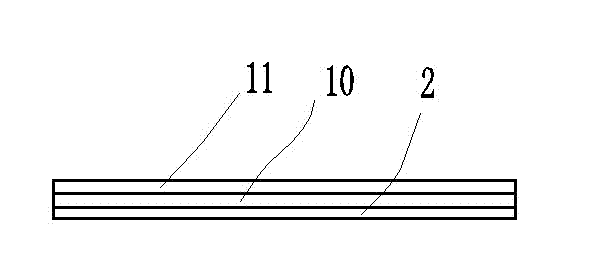

[0030] 2) Combination of leather and substrate: Apply a layer of adhesive on the back of the leather, and combine with the substrate by rolling or molding to obtain compos...

Embodiment 2

[0035] The specific scheme is the same as in Example 1, except that the polyurethane (PU) artificial leather is coated with polyurethane glue (adhesive) on the back, and is compounded with the PVC material substrate by rolling compounding process to obtain a composite leather material. The material is placed in a vacuum blister device, covered with polyurethane foam and PVC board, and then the leather is heated to 90°C, and the shaped three-layer composite leather is cooled to room temperature by a fan.

Embodiment 3

[0037] The specific scheme is the same as in Example 1, except that the back of the polyurethane (PU) artificial leather is coated with EVA hot melt adhesive, and the substrate of the polyethylene material is compounded by molding and compounding to obtain a composite leather. Put it in a vacuum blister device, cover it with polyurethane foam and PVC board, then heat the leather to 120°C, and cool the molded three-layer composite leather to room temperature by a fan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com