Laser holographic mirror anti-counterfeiting film pressure casting process

A technology of laser holography and casting technology, which is applied in the field of packaging and printing, can solve the problems of cumbersome processing technology, human health hazards, and low production efficiency, and achieve the effects of simple manufacturing technology, reduced production costs, and high anti-counterfeiting grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

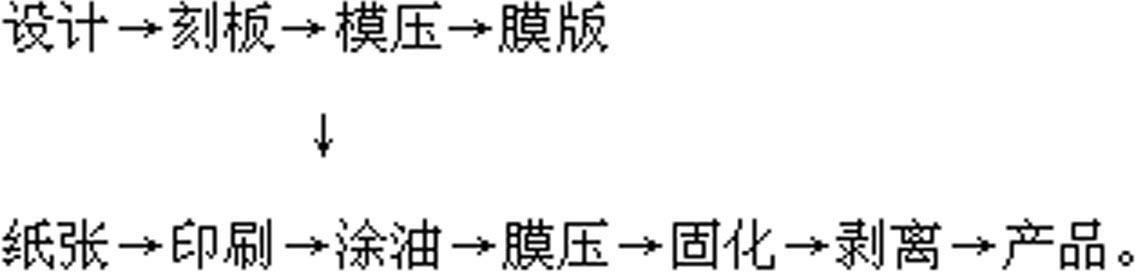

[0018] The specific process is:

[0019] 1. Design: Use the professional image software Adobe Photoshop to design and produce laser anti-counterfeiting pattern information in the computer;

[0020] 2. Stereotype: Use dot-matrix holographic lithography equipment to directly engrave the pattern information on the surface of the 0.21-0.25mm metal nickel plate, use sodium hydroxide to remove the residue on the surface of the metal nickel plate, and use it as a master plate. The resolution of the array holographic lithography machine is adjusted to 1000dpi to 1200dpi, and the exposure speed is adjusted to 35 dots / second-40 dots / second;

[0021] 3. Molding: Through the automatic molding machine, use the principle of hot molding to mold the nickel plate engraved with anti-counterfeiting pattern information and 21μm-23μm thick BOPP film to make a reusable 16-24 times with pattern information Roll-type BOPP film plate;

[0022] 4. Paper selection: This process uses gray bottom coated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com