High-pressure air-free atomization glue-applying method and device

A high-pressure airless, glue-liquid technology, which is used in adhesive application devices, pretreatment of molding materials, household components, etc. The flow rate is not easy to accurately control and other problems, to achieve the effect of good glue atomization, precise control of the amount of glue sprayed, and improved glue uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

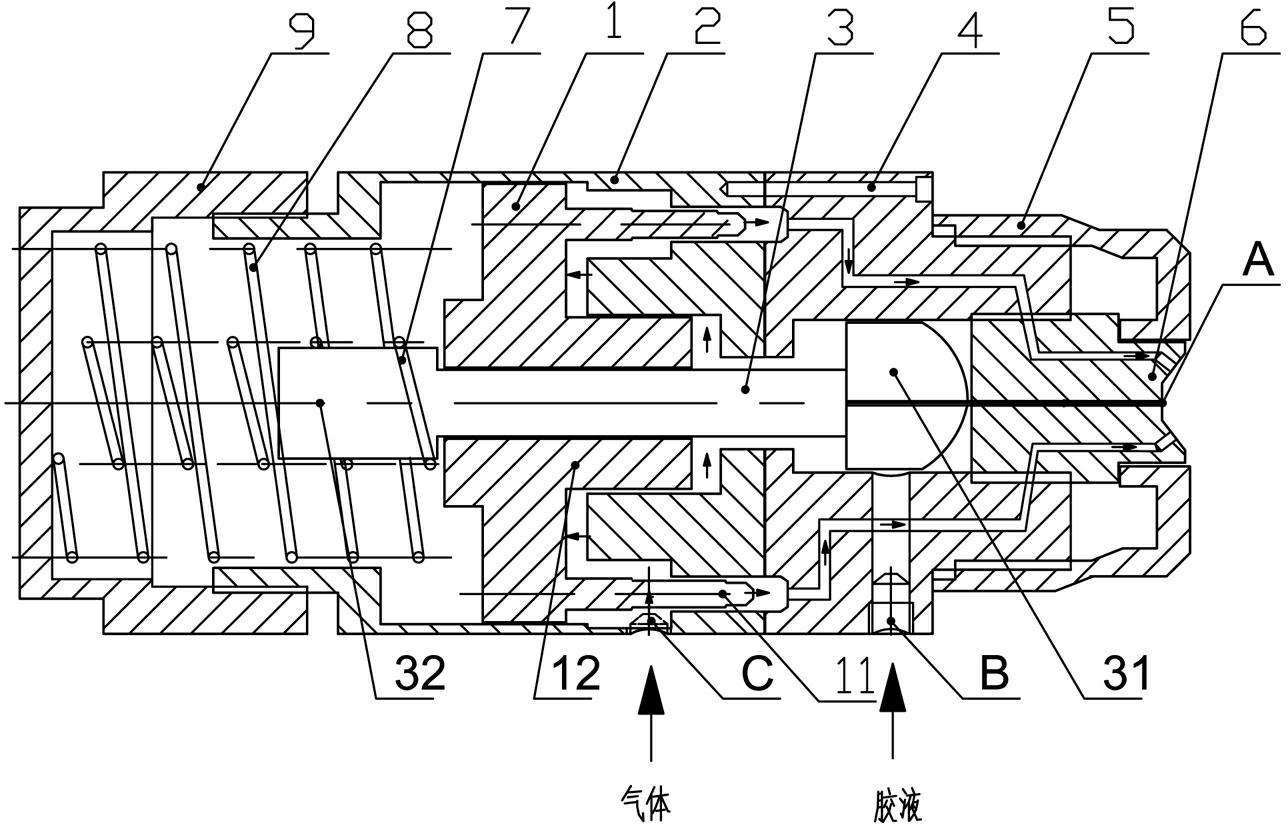

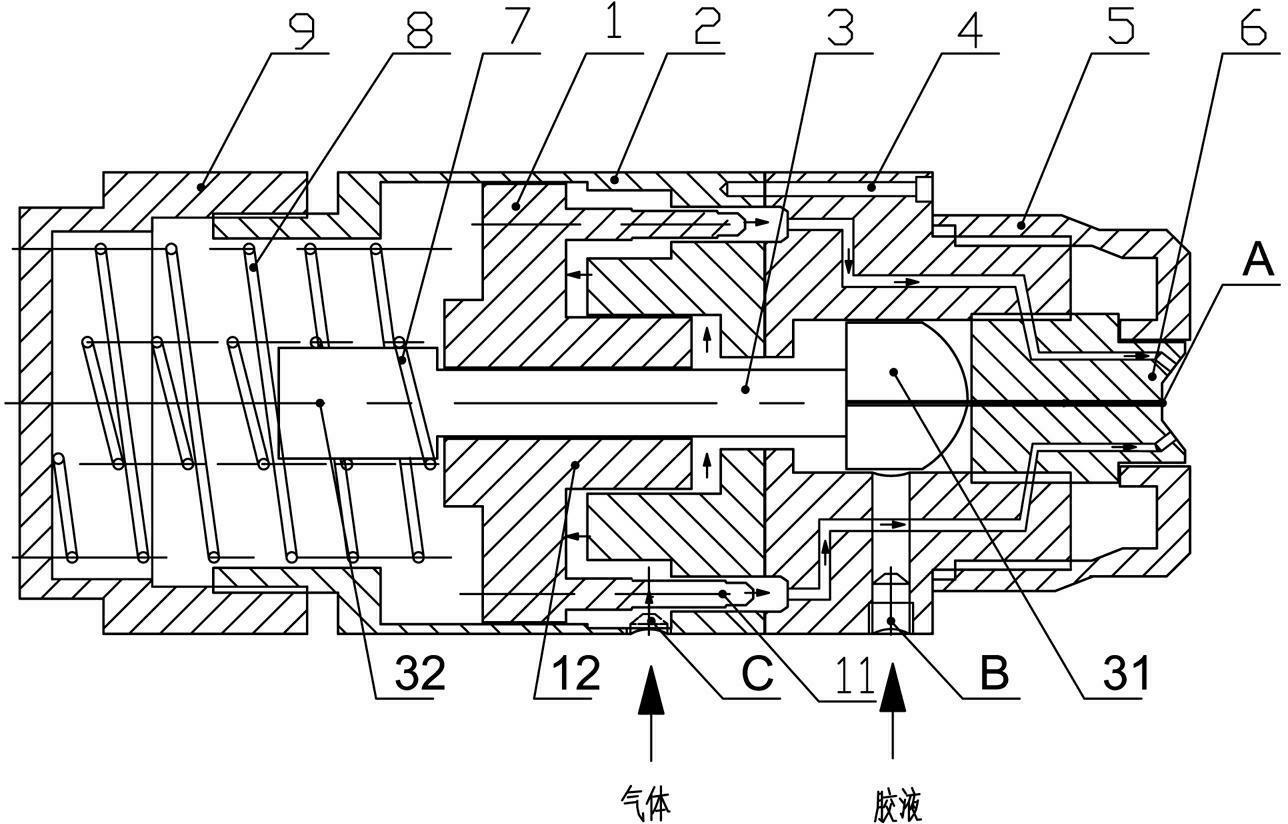

[0045] Such as figure 1 Shown, a kind of high pressure airless atomization sizing device, it comprises:

[0046] A chamber part, on this chamber part, be provided with a chamber that runs through longitudinally, the downstream front port and the upstream rear port of this chamber are closed, and the glue liquid channel that communicates with the outside is provided on the closed end of the front end and Gas passage, the downstream port of glue passage forms glue spray A, and the downstream port of gas passage forms gas spout; This glue passage and gas passage are all communicated with described chamber; Be provided with glue inlet in described glue passage B. A gas inlet C is provided on the side wall of the chamber corresponding to the upstream end point of the reciprocating stroke of the piston rod, and the two inlets communicate with the outside world;

[0047] A piston device, it comprises a piston rod 3, the downstream end of this piston rod is provided with piston 31, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com