Ladle bottom structure of continuous casting ladle

A technology of continuous casting and encapsulation, which is applied to casting equipment, casting molten material containers, metal processing equipment, etc., can solve difficulties and problems that have not been applied, and achieve low production costs, increased metal yield, and simple construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings. This invention may, however, be embodied in many different forms and should not be construed as limited to the exemplary embodiments set forth herein. In the drawings, the sizes of parts may be exaggerated for clarity, and like reference numerals will designate like parts throughout.

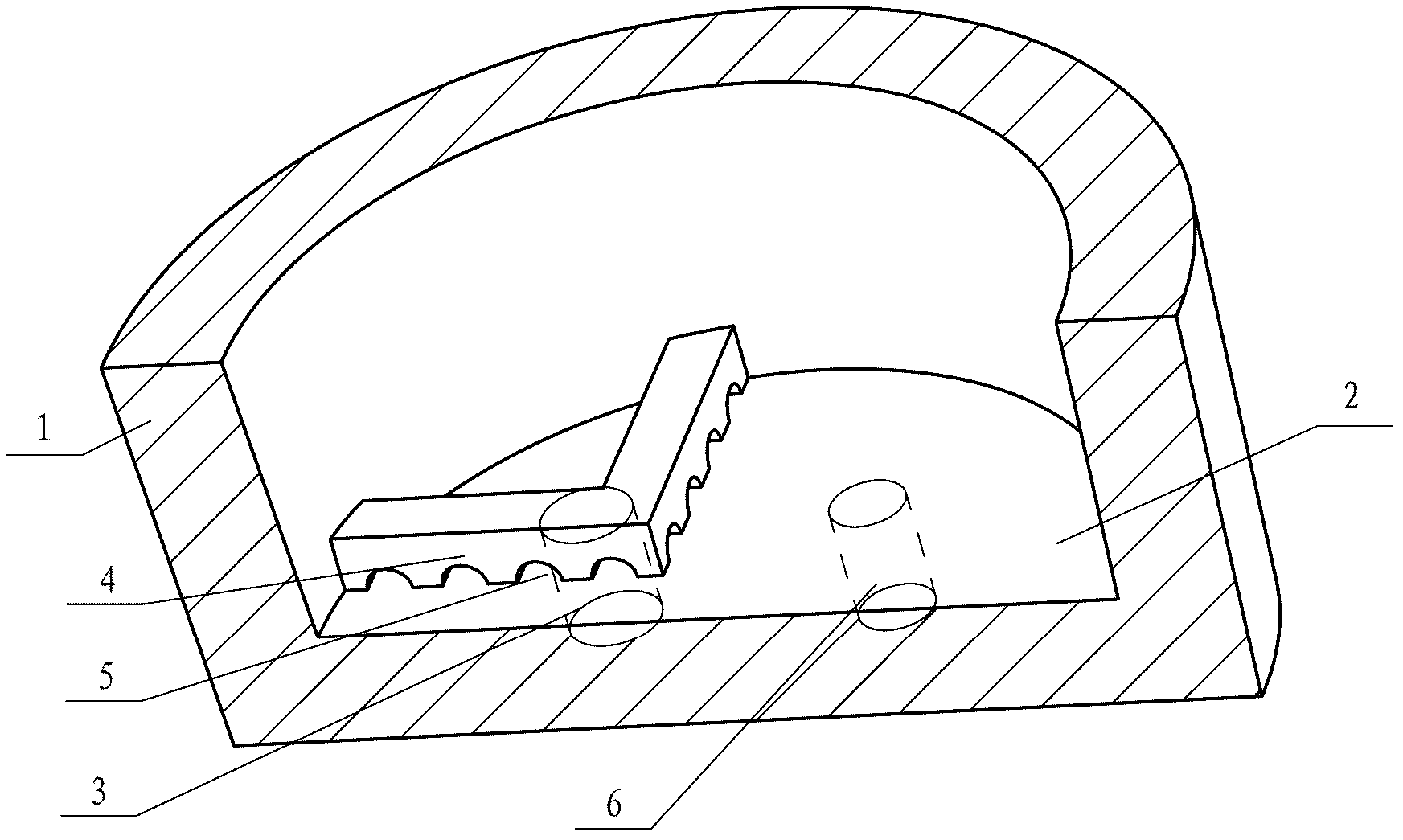

[0023] figure 1 is a schematic cutaway perspective view showing a continuous casting ladle bottom structure according to an exemplary embodiment of the present invention.

[0024] Such as figure 1 As shown in , the continuous casting ladle according to an exemplary embodiment of the present invention can have a cylindrical bag body 1 and a bag bottom 2 closing the bottom of the bag body 1, and a hole penetrating through the bag bottom 2 can be opened on the bag bottom 2 Nozzle 3 of thickness.

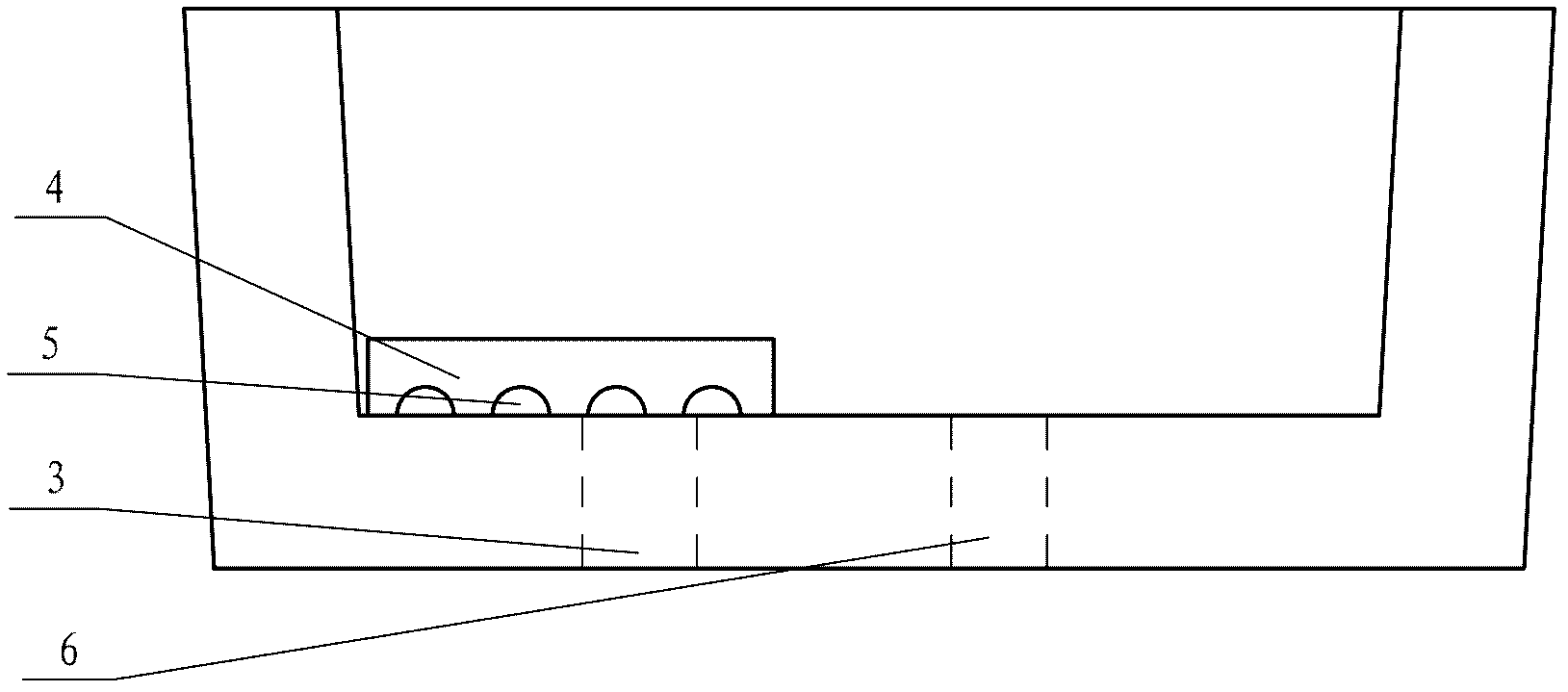

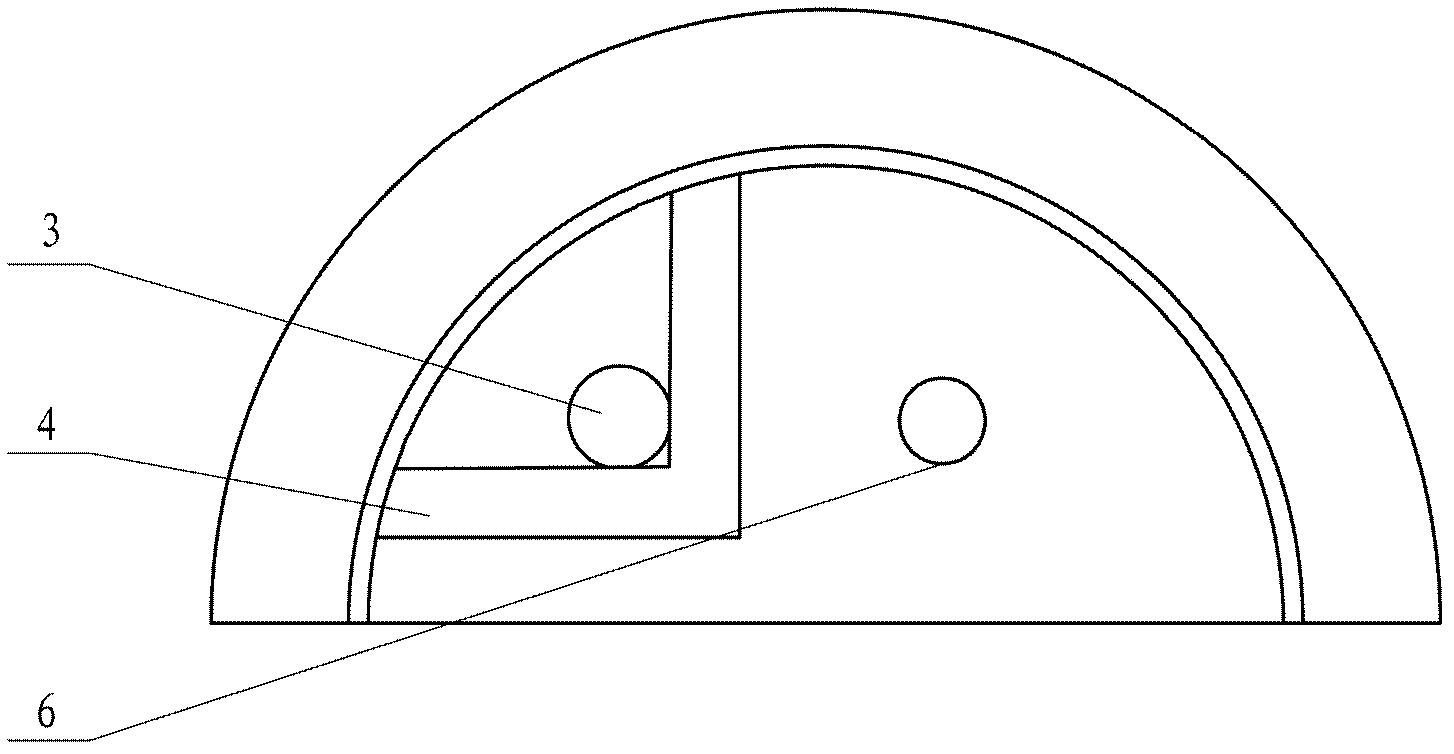

[0025] figure 2 yes figure 1 A schematic front view of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com