Combined combustion energy conversion flue-cured tobacco furnace

A technology of energy conversion and flue-cured tobacco, which is applied in the field of flue-cured tobacco furnaces, can solve the problems of small one-time feeding of gasifiers, the inability to use firewood, coal or biomass, and a single variety of fuels, so as to achieve good heat dissipation, reduce feeding frequency, The effect of improving the utilization rate of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

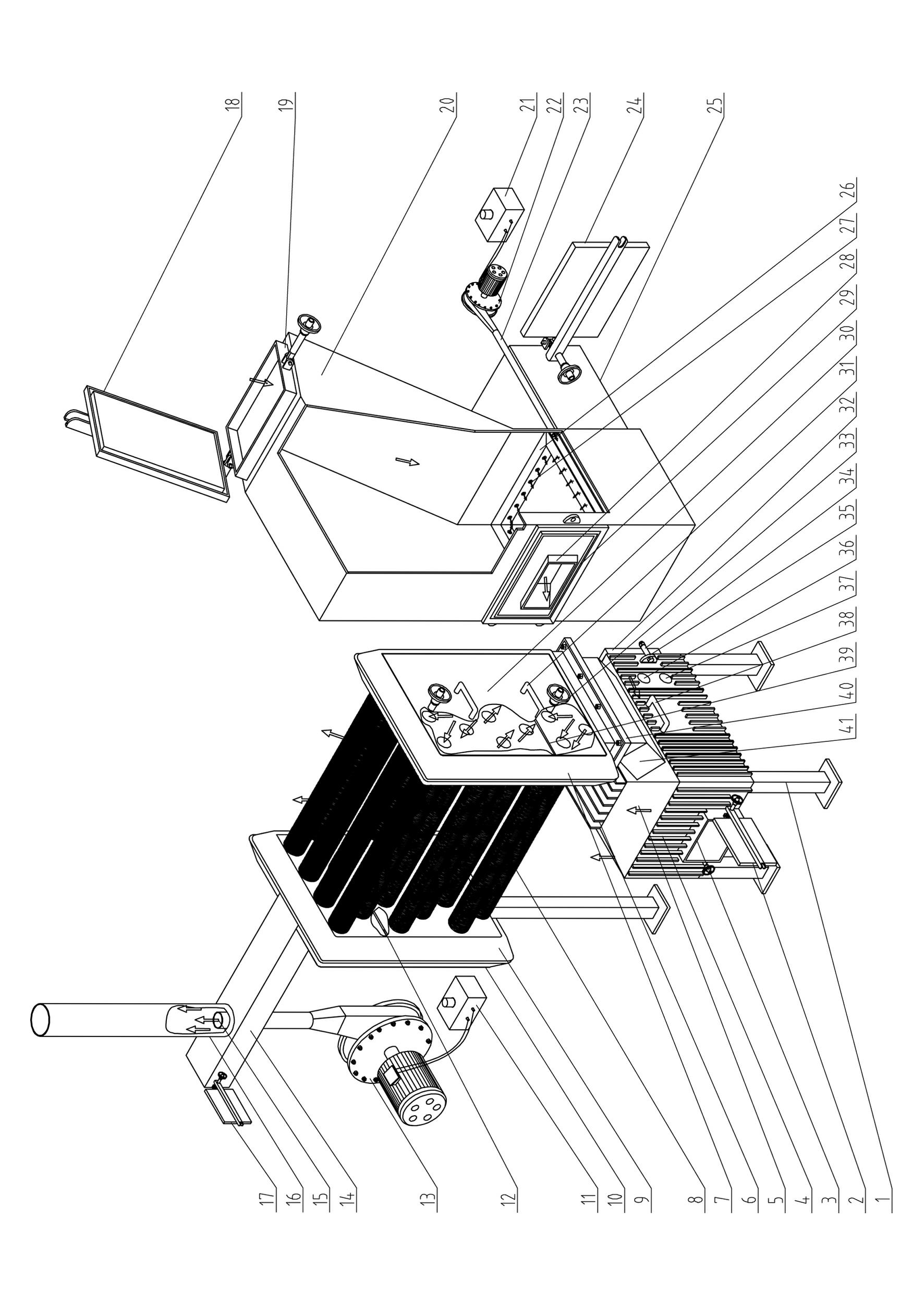

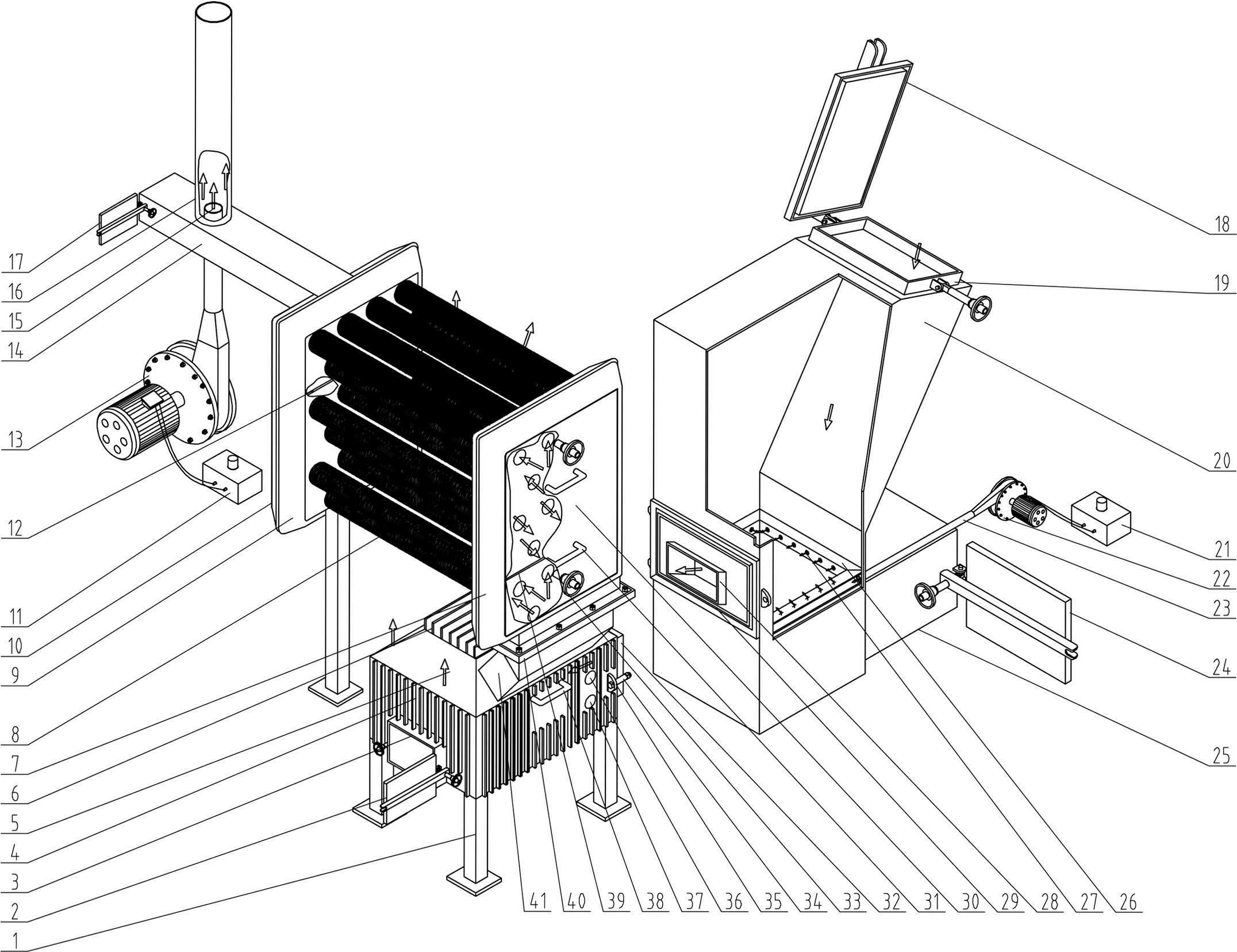

[0020] Such as figure 1 As shown, a co-combustion energy conversion flue-cured tobacco furnace includes a thermal reaction furnace, a heat exchange mechanism, and a smoke exhaust mechanism. The heat generated by the thermal reaction furnace is released through the heat exchange mechanism; the main body of the thermal reaction furnace is a gasification chamber 20 for fuel. , the gasification chamber is a vertical box, the upper part of the gasification chamber 20 is designed as an inverted trapezoid, the upper part is provided with a feed hopper 19, the feed hopper 19 is closed by the feed hopper door 18, and the lower part of the gasification chamber is provided with an ash discharge hopper 25. The ash hopper 25 and the ash hopper door 24 are closed; the heat exchange mechanism is connected with the cavity of the gasification chamber. The lower part is horizontally designed with an annular air supply tube 26, and the circumference of the air supply tube 26 is evenly opened wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com