Formation method of lithium ion battery

A technology of lithium ion battery and chemical formation method, which is applied in the field of high current formation of lithium ion batteries, can solve problems such as low production efficiency and long formation process time, and achieve the effects of good electrical performance, shortening formation time and improving low temperature performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

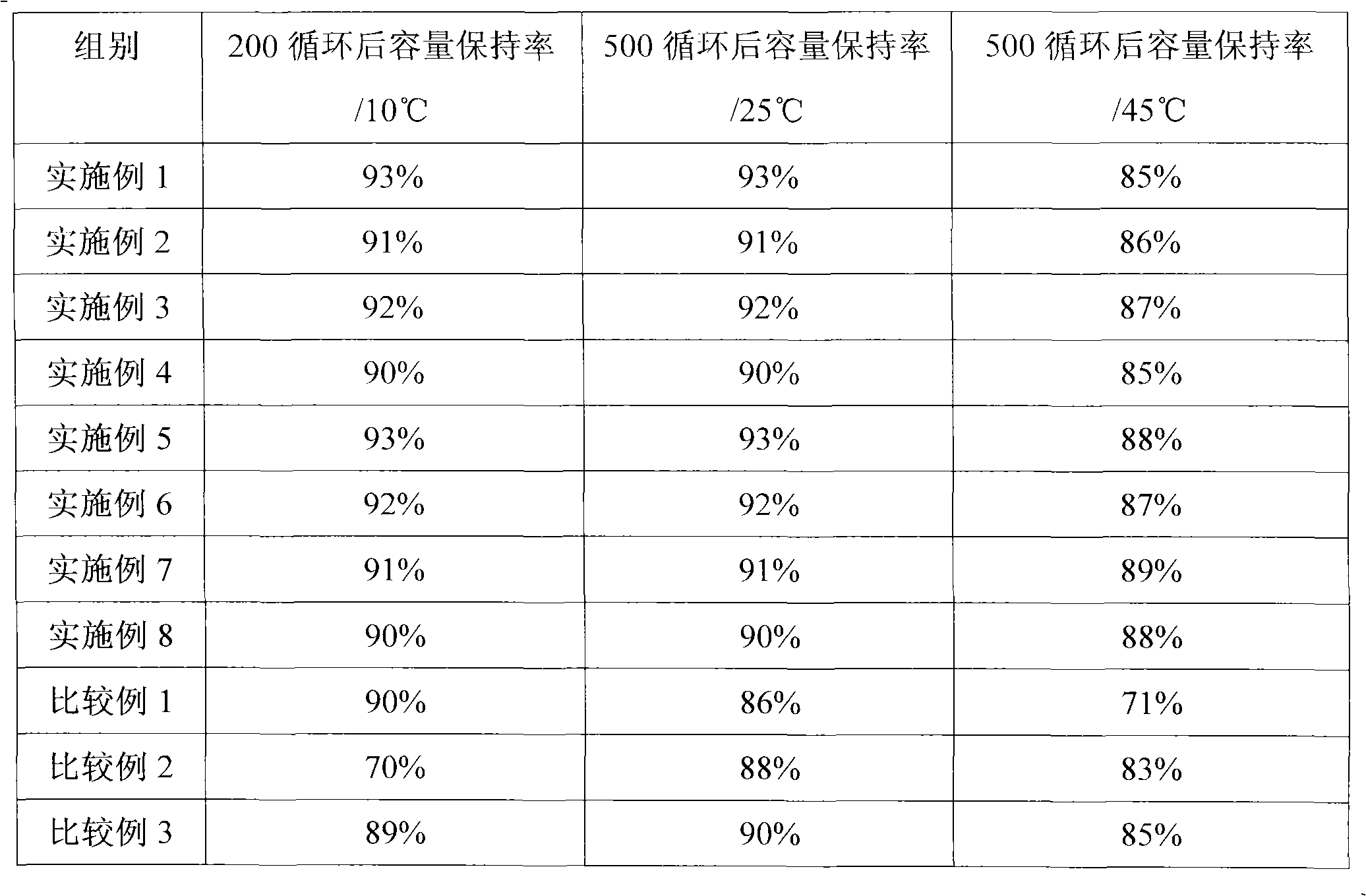

Examples

Embodiment 1

[0028] Preparation of positive electrode sheet: LiCoO 2 (Lithium cobalt oxide), Super-P (conductive carbon black), PVDF (polyylidene fluoride resin) are mixed with NMP (N, N-dimethylpyrrolidone) in a mass ratio of 95:2:3 and stirred evenly to obtain a positive electrode Sheet Coating Slurry. Viscosity was adjusted by NMP during stirring. Then the slurry was uniformly coated on both sides of a 14 micron thick positive electrode current collector (aluminum foil) according to a certain width, and finally cold pressed and sliced to obtain positive electrode sheets.

[0029] Preparation of the negative electrode sheet: MCMB (a kind of anode graphite, mesophase pitch-based carbon microspheres), Super-P (conductive carbon black), CMC (water-based binder, carboxymethyl cellulose), SBR ( Styrene Butadiene Rubber (a kind of rubber) is mixed with deionized water in a mass ratio of 94:1:2:3 and stirred evenly to obtain a negative electrode coating slurry. The viscosity was adjusted b...

Embodiment 2

[0032] Lithium-ion batteries were prepared according to the method described in Example 1. The difference was that the amount of electrolyte solution injected during the first liquid injection was 2.47 grams, and after standing for half an hour, it was charged with a current of 0.1C for 60 minutes for opening formation, and the charging capacity was 10% of the battery's rated capacity. Then add 0.19 grams of succinonitrile (SN) to 1.14 grams of the above-mentioned electrolyte and mix evenly, then inject the electrolyte containing the SN additive into the cell shell for the second injection, and quickly seal it to make a 053450 lithium-ion battery .

Embodiment 3

[0034] Lithium-ion batteries were prepared according to the method described in Example 1. The difference was that the amount of electrolyte solution injected during the first liquid injection was 3.23 grams, and after standing for half an hour, it was charged with a current of 1.5C for 3 minutes for opening formation, and the charging capacity was 8% of the battery's rated capacity. Then add 0.038 grams of ethylene sulfate (DTD) to 0.532 grams of the above electrolyte and mix evenly, then inject the electrolyte containing DTD additive into the cell shell for the second injection, and quickly seal it to make a 053450 lithium-ion battery .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com