Gradual vapouration type high-energy-efficiency direct-flow steam injection boiler and method

A high-energy-efficiency, steam-injection technology, which is applied to steam boilers, mining fluids, steam generation, etc., can solve problems such as high flue gas temperature, burning and bursting tubes, and energy waste, so as to improve heat utilization, reduce equipment costs and Operating cost and the effect of reducing the probability of pipe burst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

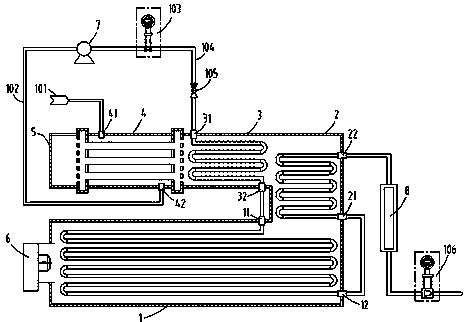

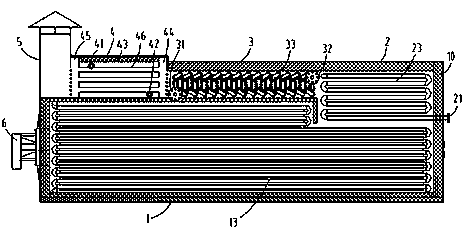

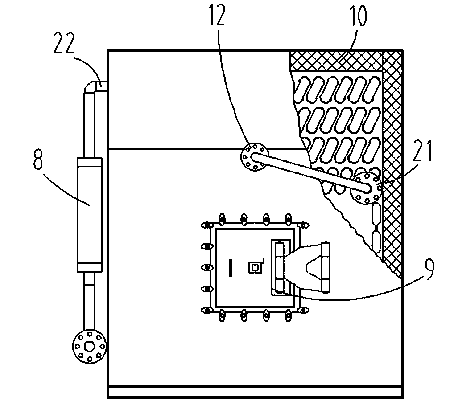

[0028] refer to figure 1 , figure 2 , image 3 , the present invention provides a slow-vaporization high-efficiency once-through steam injection boiler, which is mainly composed of four modules and accessories, wherein the four modules are: radiation water cooling module 1, slow vaporization module 2, water pipe convection module 3 and smoke pipe Water bath module 4; accessories mainly include: chimney 5, burner 6, high-pressure water pump 7, sampling separator 8, maintenance manhole 9, furnace body insulation 10, low-pressure water flow pipeline 102, water flow throttling component 103, high-pressure water vapor flow Pipeline 104, check valve 105, steam flow throttling assembly 106, instrumentation and electric control system, etc.

[0029] The radiant water cooling module 1 adopts a square membrane water cooling wall 13 structure, and is placed horizontally at the bottom of the boiler center. The gradual vaporization module 2 is designed as a square bend structure, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com