Manual high-pressure engine oil compensator of turbine pressurizer of diesel engine

A turbocharger, diesel engine technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of military vehicles not meeting the requirements of the battlefield environment, difficult to drive, waste of energy, etc., to achieve lubrication and cooling. Good effect, large oil supply, strong anti-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail.

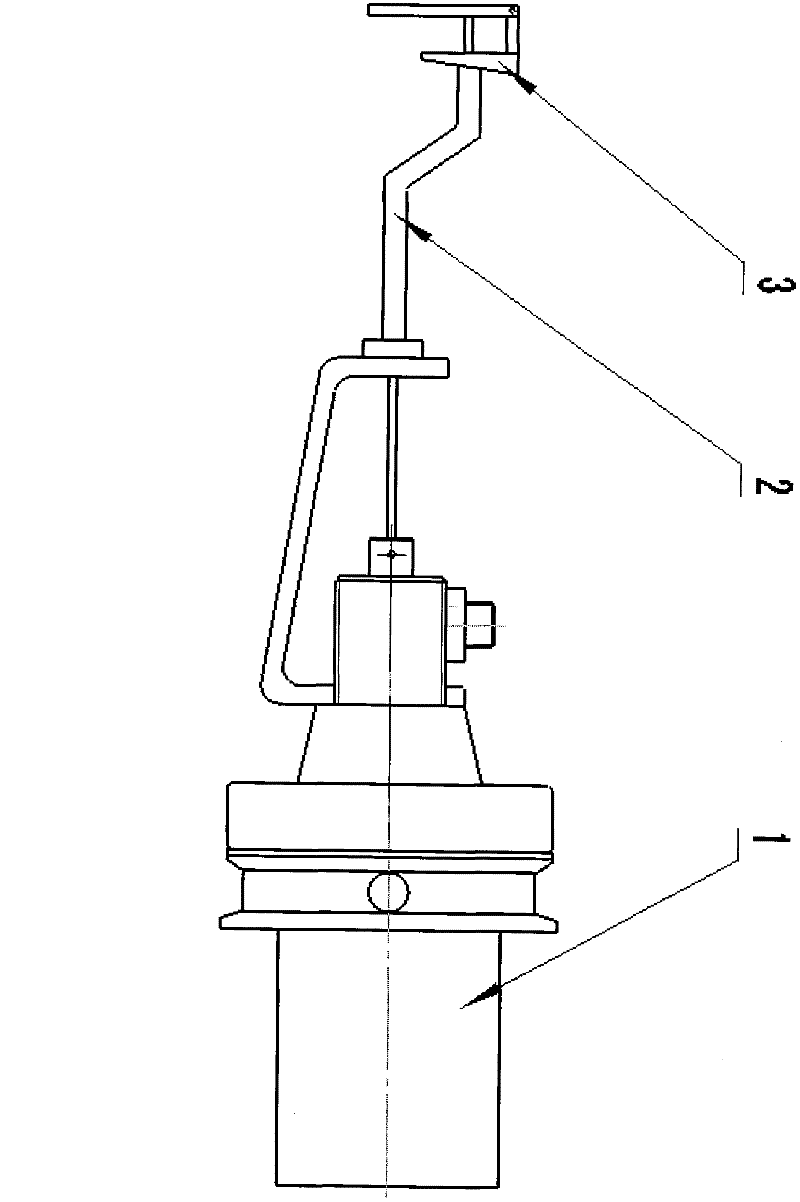

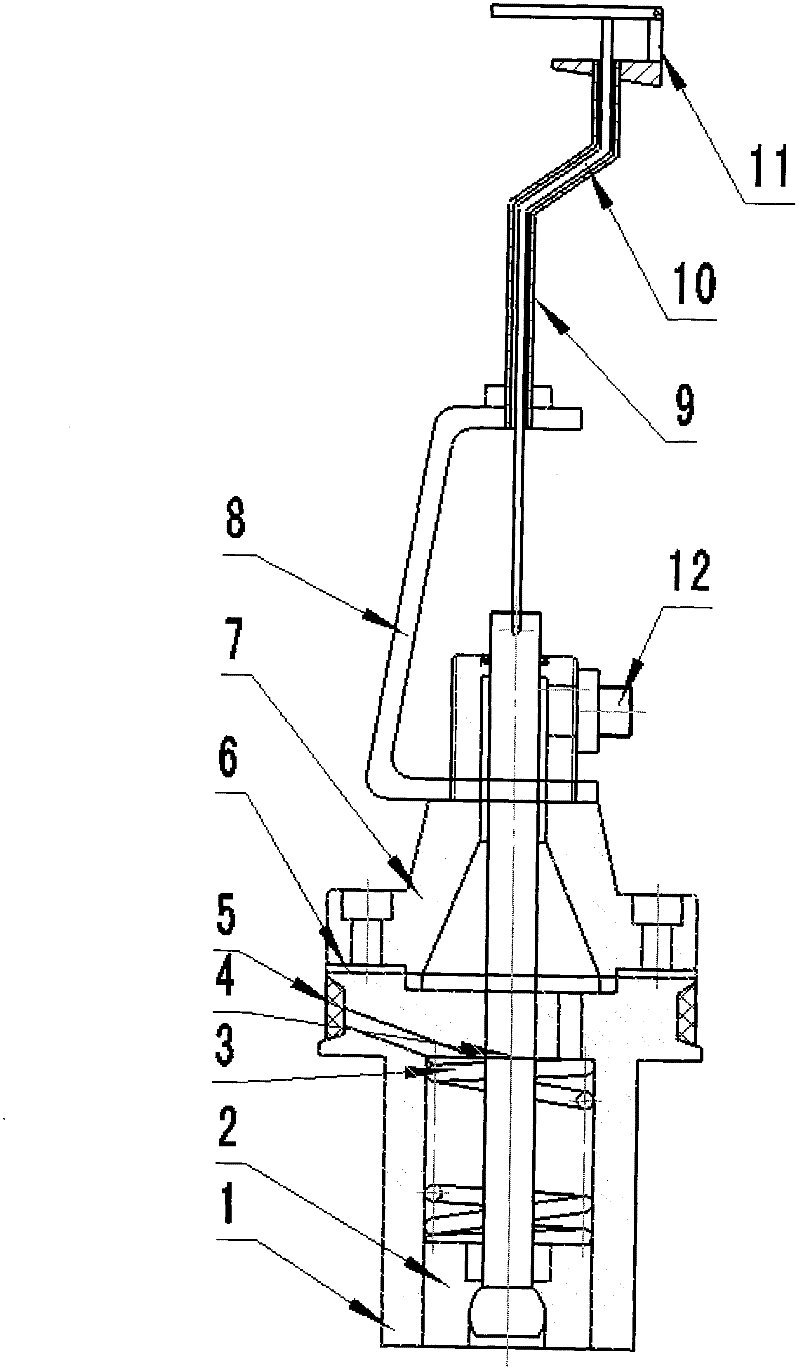

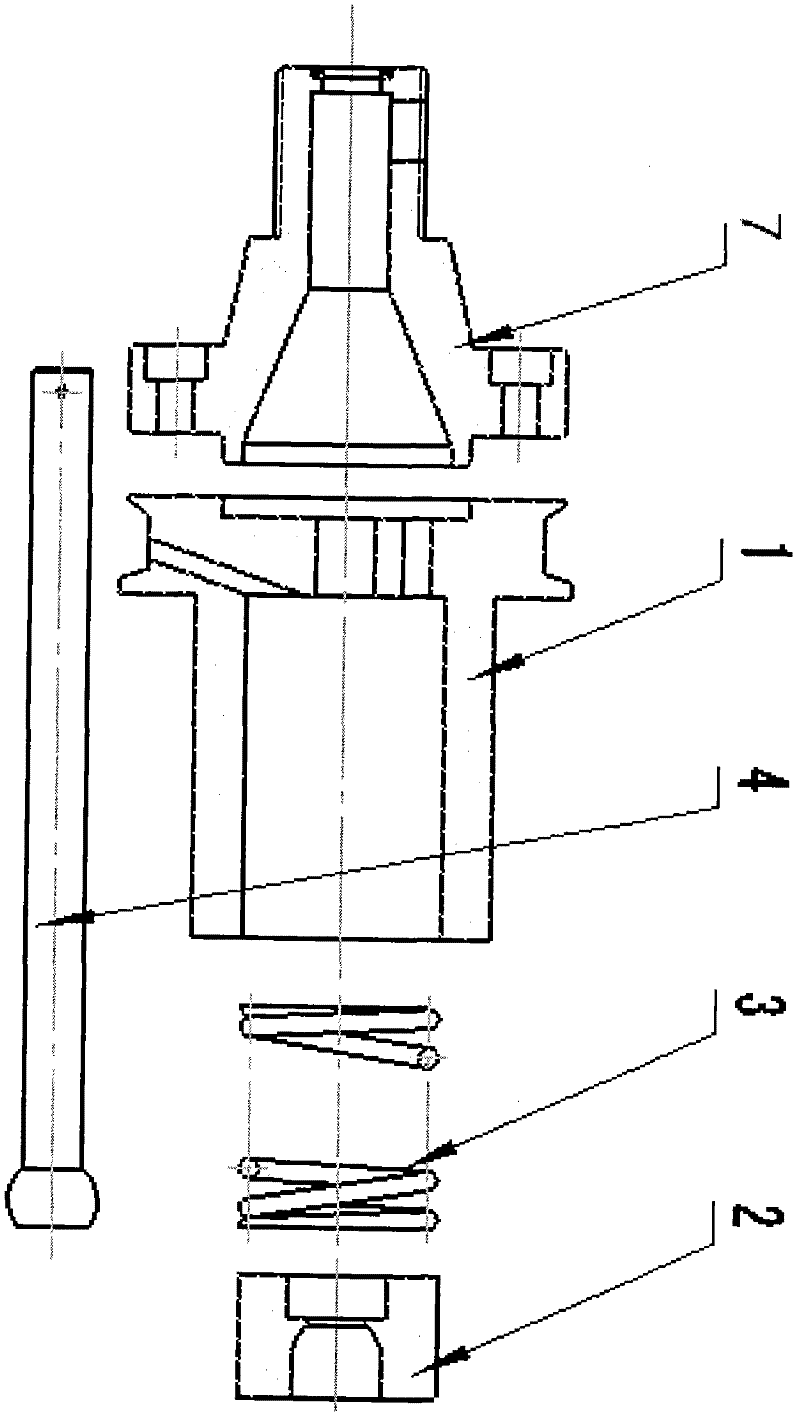

[0013] Such as figure 1 As shown, the present invention includes: manual high-pressure oil pump assembly, such as figure 1 \1, power flexible shaft such as figure 1 \2, operation handle such as figure 1 \3, consists of three parts. The following introduces the structural design and working principle of the manual oil pump; first, the present invention is designed on the basis of the principles of simple design structure, high power efficiency, lowest cost of use, and minimizing the impact on the engine structure during installation. The oil compensator with manual high-pressure oil pump as the main body, because this oil compensator works when the engine stops running, it is impossible to use mechanical power to drive it. If it is driven by a locomotive battery, the power of the battery will be consumed. It will affect vehicles started at low temperature, es...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com