Universal ceramic tile used for wall surface and ground

A tile and floor technology, applied in covering/lining, construction, building construction, etc., can solve the problem of poor wear resistance of floor tiles and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

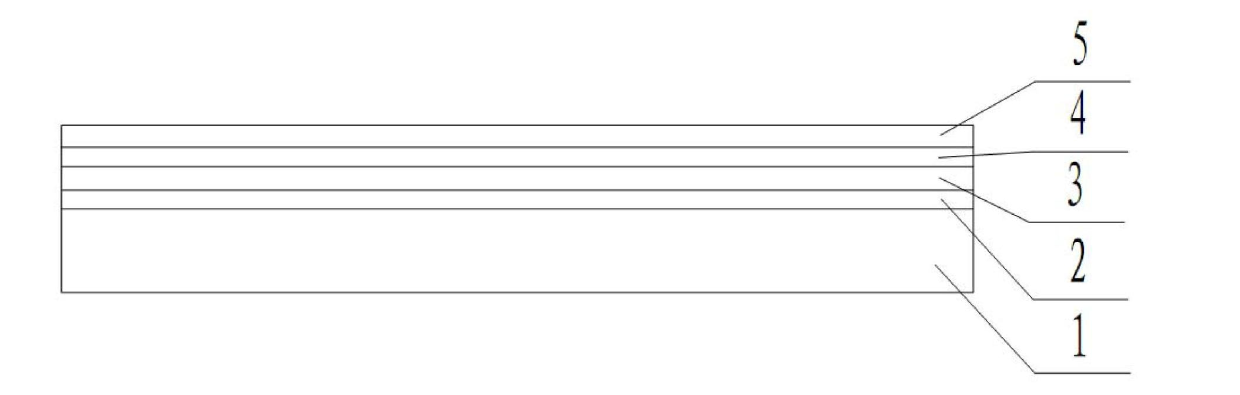

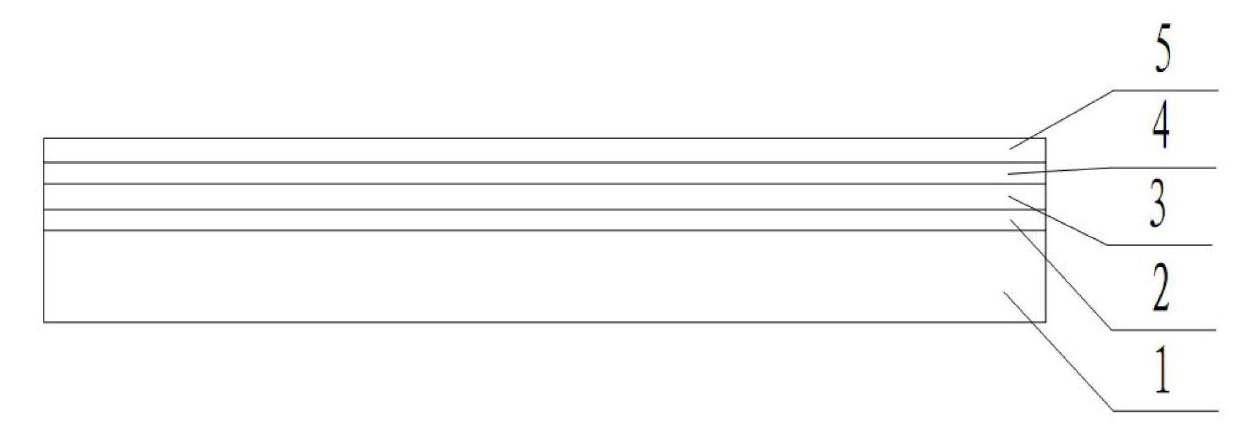

[0011] like figure 1 A general-purpose ceramic tile for walls and floors is shown, including an embryo body 1, an underglaze 2, and a printing layer 3. The printing layer has a wear-resistant glaze layer 4 containing corundum particles, and a rough thin-layer patch is fired on the surface 5. The water absorption rate of the embryo body 1 is 0.5%<E≤3%. The thin-layer patch 5 is made of metal oxide particles such as aluminum oxide, iron oxide, and zinc oxide. The printing layer 3 is made by 3D digital inkjet and three-dimensional mold surface technology.

[0012] The product of the present invention has the following technical characteristics:

[0013] 1. The water absorption rate is 0.5% < E ≤ 3%, which belongs to the stoneware body, so it can be used for walls and floors.

[0014] Second, the natural concave and convex three-dimensional rock surface molding effect, combined with slate, mica, and wear-resistant slate, the natural texture and gloss of the rock surface are com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com