RAP regeneration mixing device

A technology of mixing device and mixing cavity, which is applied in the field of RAP regeneration mixing device, can solve the problems of wasting resources, destroying the environment, violating the environment-friendly and resource-saving type, etc., and achieving the effect of saving energy and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

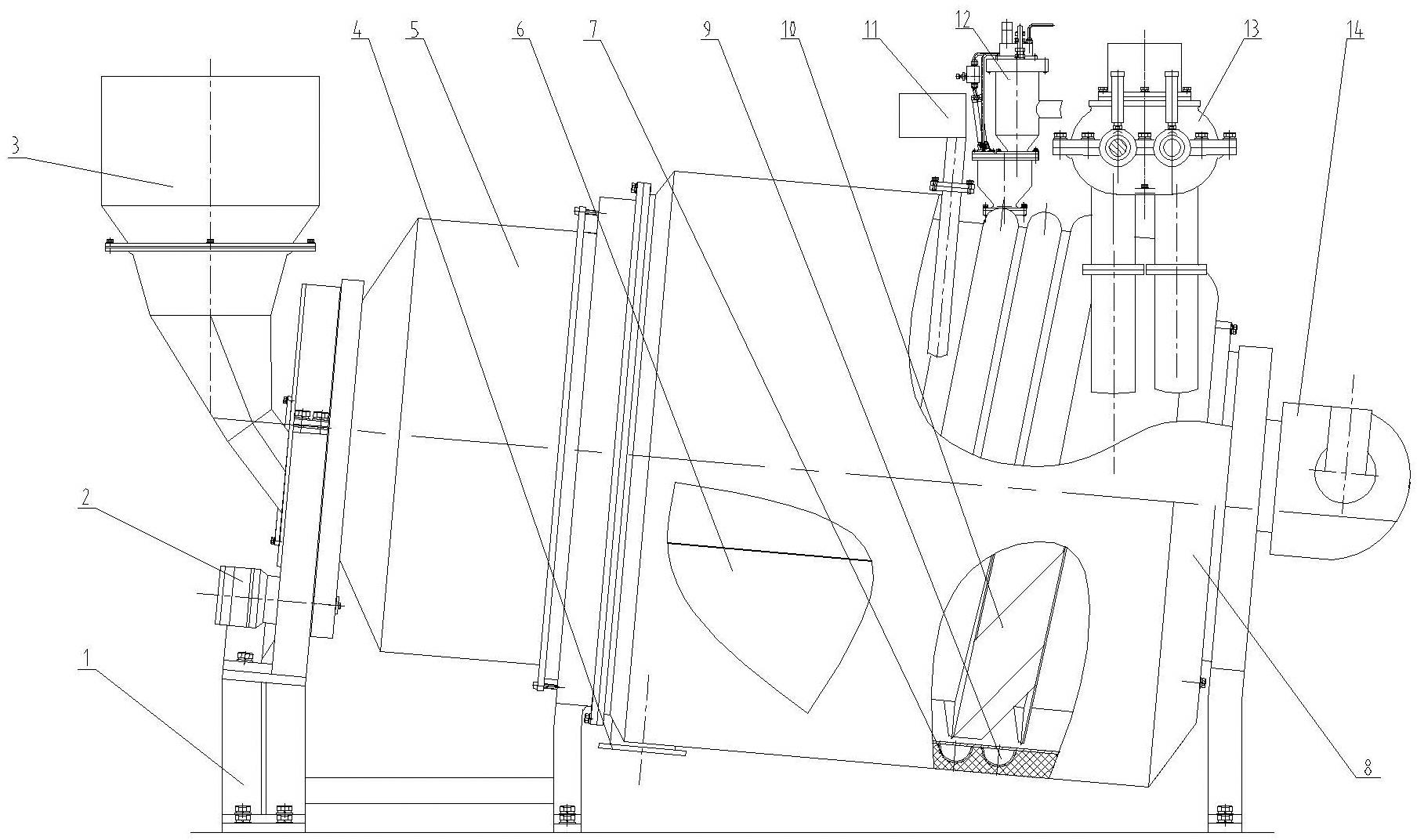

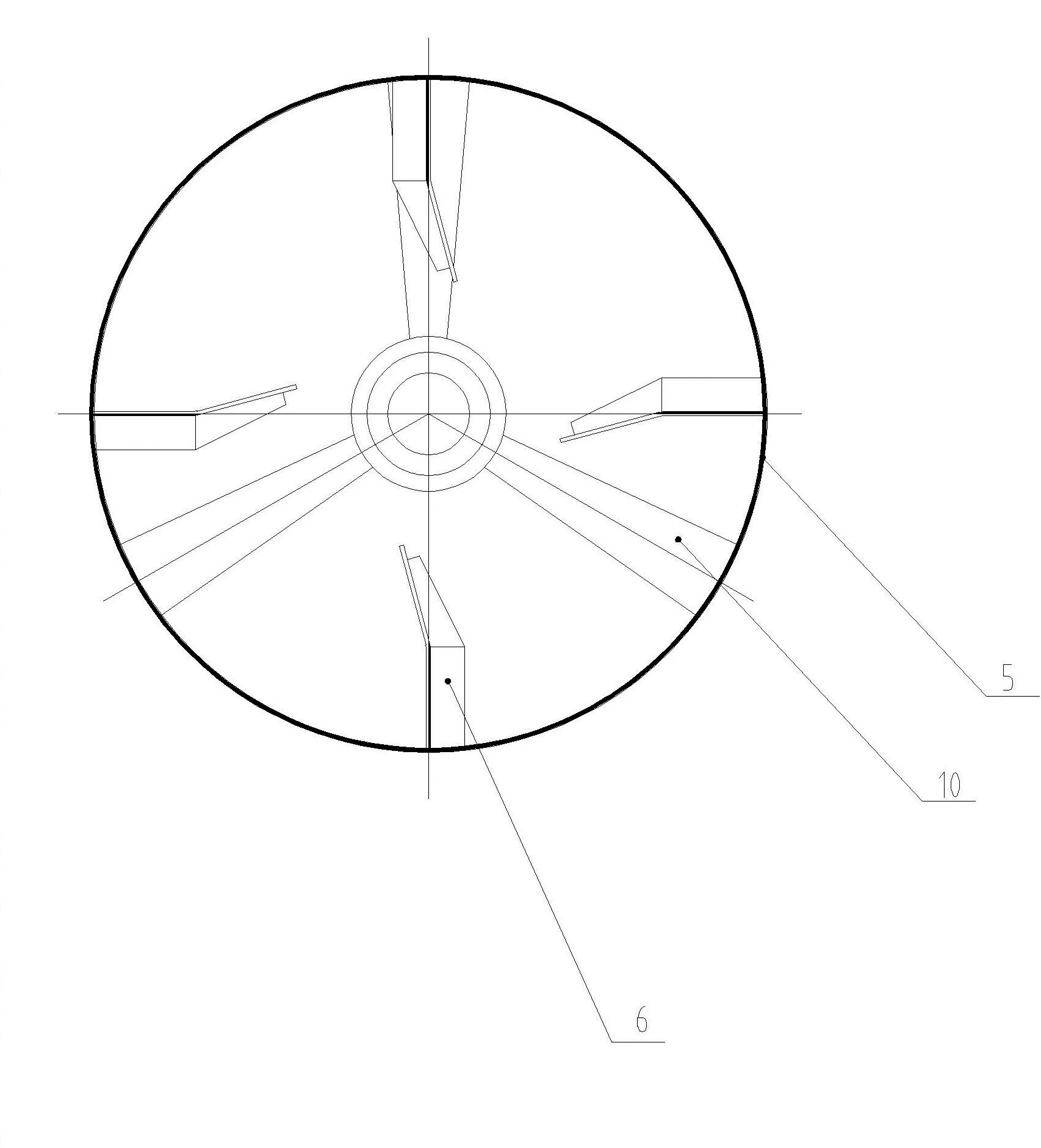

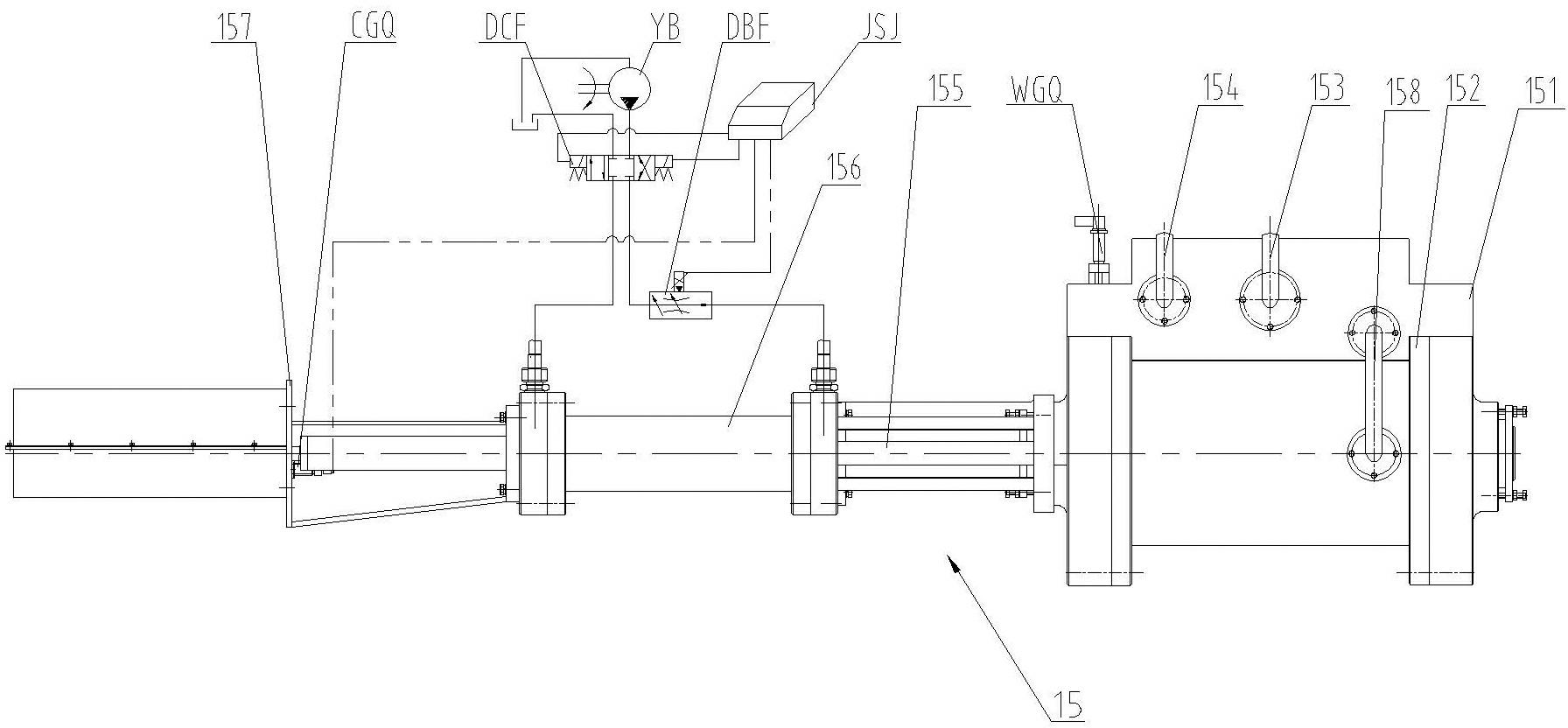

[0017] Such as Figure 1 to Figure 4 As shown, the RAP regenerative mixing device provided by the present invention mainly includes a support 1, a hollow roller shaft 5, an oil motor 2, and a burner 14, and the roller shaft 5 is installed on the support 1 with a high front and a low rear; The front end of the roller shaft 5 has a new collecting hopper 3, and the rear section of the roller shaft 5 has a casing 8, and a jacket is formed between the casing 8 and the roller shaft 5. There are spiral blades 6 on the inner wall of the roller shaft 5, and spiral blade paddles on the outer wall. 10. There is a mixing chamber 8 at the end of the jacket; the burner 14 is located behind the mixing chamber 8, and its combustion port is located in the mixing chamber 8, and the oil motor 2 is engaged with the outer wall of the front section of the roller shaft 5. The direction of rotation of the helical blade 6 is the same as that of the roller shaft 5, and its length is equal to the length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com