Powdered material used for preparing high-temperature abrasion-proof anticorrosion cladding layer and preparation method

A powder material, high-temperature wear-resistant technology, applied in metal material coating process, coating, molten spraying, etc., can solve the problems of poor high-temperature chlorine corrosion resistance, peeling failure, poor wear resistance, etc., to achieve wear resistance The effect of long corrosion life, low preparation cost and low dilution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

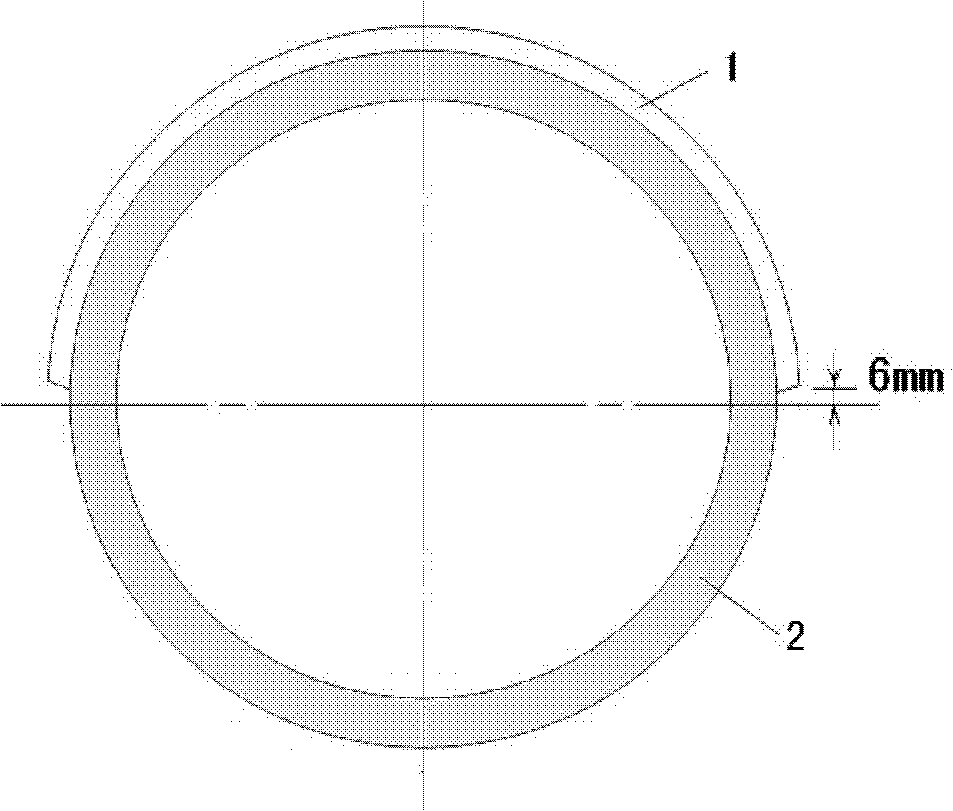

[0037] Example 1: Preparation of wear-resistant and corrosion-resistant cladding layer on the heating surface of the water-cooled wall tube

[0038] 1. Preparation of mixed powder

[0039] 1. Preparation of powder raw materials

[0040] The weight percent scope of described powder raw material is as follows:

[0041] NbC powder (particle size-140+300 mesh, purity ≥99.5%): 10wt.%; TiC powder (particle size-150+300 mesh, purity ≥99.5%): 4wt.%; Ti powder (particle size-150+300 mesh, Purity ≥ 99.5%): 1wt.%; VC powder (particle size -140+300 mesh, purity ≥ 99.5%): 4wt.%; Ni-Cr-Mo alloy powder (particle size -140+325 mesh): balance; Among them, the composition of Ni-Cr-Mo alloy powder is: Cr: 25wt.%, Mo: 15wt.%, Co: 1wt.%, W: 3wt.%, Ni: balance; Ni-Cr-Mo alloy The powder is prepared by the existing mature gas atomization method.

[0042] 2. Preparation process of mixed powder

[0043] (1) According to the various powder ratios described in step 1, weigh the various powders requ...

Embodiment 2

[0054] Example 2: Preparation of wear-resistant and corrosion-resistant cladding layer on the outer surface of the economizer tube

[0055] 1. Preparation of mixed powder

[0056] 1. Preparation of powder raw materials

[0057] The weight percent scope of described powder raw material is as follows:

[0058] NbC powder (particle size-140+300 mesh, purity ≥99.5%): 11wt.%; TiC powder (particle size-150+300 mesh, purity ≥99.5%): 5wt.%; Ti powder (particle size-150+300 mesh, Purity ≥ 99.5%): 1.5wt.%; VC powder (particle size -140+300 mesh, purity ≥ 99.5%): 4wt.%; Ni-Cr-Mo alloy powder (particle size -140+325 mesh): balance ; Among them, the composition of Ni-Cr-Mo alloy powder is: Cr: 27wt.%, Mo: 13wt.%, Co: 1wt.%, W: 3wt.%, Ni: balance; Ni-Cr-Mo system Alloy powder is prepared by the existing mature gas atomization method.

[0059] 2. Preparation process of mixed powder

[0060] (1) According to the various powder ratios described in step 1, weigh the various powders require...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com