Iron nickel chrome molybdenum base powder for laser cladding and method for preparing same

A powder material, laser cladding technology, applied in the direction of metal material coating process, coating, etc., can solve the problem of low bonding strength, and achieve the effects of long corrosion resistance life, wear resistance of the cladding layer, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

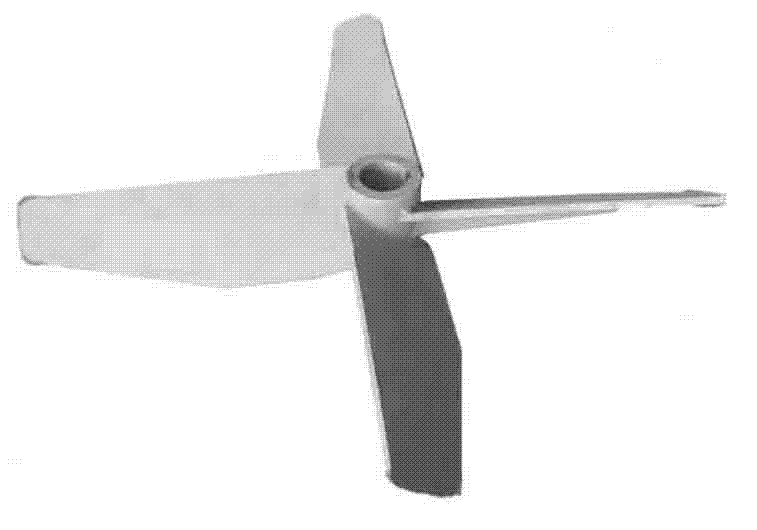

[0032] Example 1: Preparation of a wear-resistant and corrosion-resistant cladding layer on the surface of the agitator blade

[0033] 1. Preparation of powder materials

[0034] 1. Preparation of powder raw materials: the weight percentage range of the powder raw materials is as follows:

[0035] Titanium powder (particle size-140+325 mesh, purity 99.5%): 12wt.%; graphite carbon powder (purity 99%): 3 wt.%; niobium carbide powder (particle size-140+325 mesh, purity 99.5%): 8 wt.%; iron-nickel-chromium-molybdenum alloy powder (grain size-140+325 mesh): balance; wherein, the composition of iron-nickel-chromium-molybdenum alloy powder is: nickel: 20wt.%, chromium: 23wt. %, molybdenum: 8wt.%, iron: balance.

[0036]Iron-nickel-chromium-molybdenum alloy powder is prepared by the existing mature gas atomization method.

[0037] 2. Mixing process of powder raw materials

[0038] (1) According to the various powder ratios described in step 1, weigh the various powders required fo...

Embodiment 2

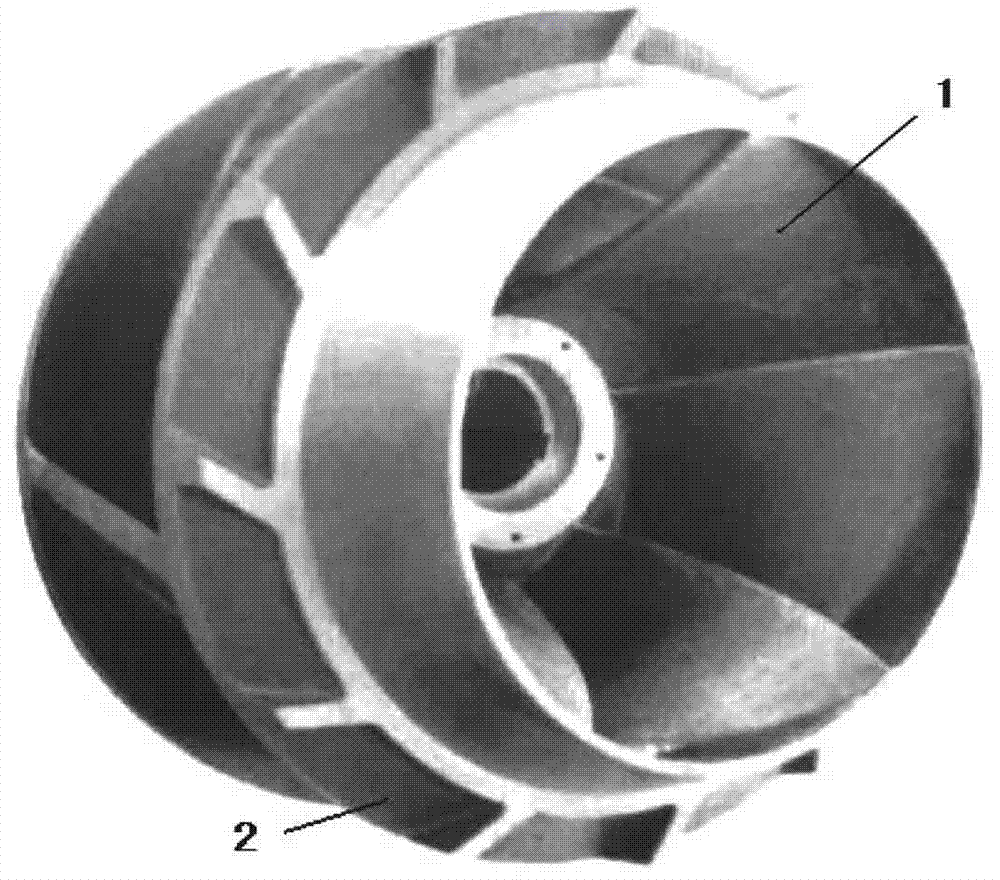

[0051] Example 2: Preparation of wear-resistant and corrosion-resistant cladding layer on the surface of the impeller of the slurry circulation pump

[0052] 1. Preparation of powder materials

[0053] 1. Preparation of powder raw materials: the weight percentage range of the powder raw materials is as follows:

[0054] Titanium powder (particle size-140+325 mesh, purity 99.5%): 15 wt.%; graphite carbon powder (purity 99%): 3.7wt.%; niobium carbide (NbC) powder (particle size-140+325 mesh, purity 99.5 %): 10 wt.%; iron-nickel-chromium-molybdenum alloy powder (grain size -140+325 mesh): balance; among them, the composition of iron-nickel-chromium-molybdenum alloy powder is: nickel: 26wt.%, Chromium: 25wt.%, molybdenum: 10wt.%, iron: balance.

[0055] 2. Mixing process of powder raw materials

[0056] (1) According to the various powder ratios described in step 1, weigh the various powders required for the powder raw materials;

[0057] (2) Put the powder raw material into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com