Preparation method of magnesium-zinc-tricalcium phosphate composite material by powder hot pressed sintering

A composite material, magnesium zinc phosphoric acid technology, applied in the field of magnesium zinc tricalcium phosphate composite materials, can solve problems such as material difficulties, and achieve the effects of accurate content, high feasibility, and precise component control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

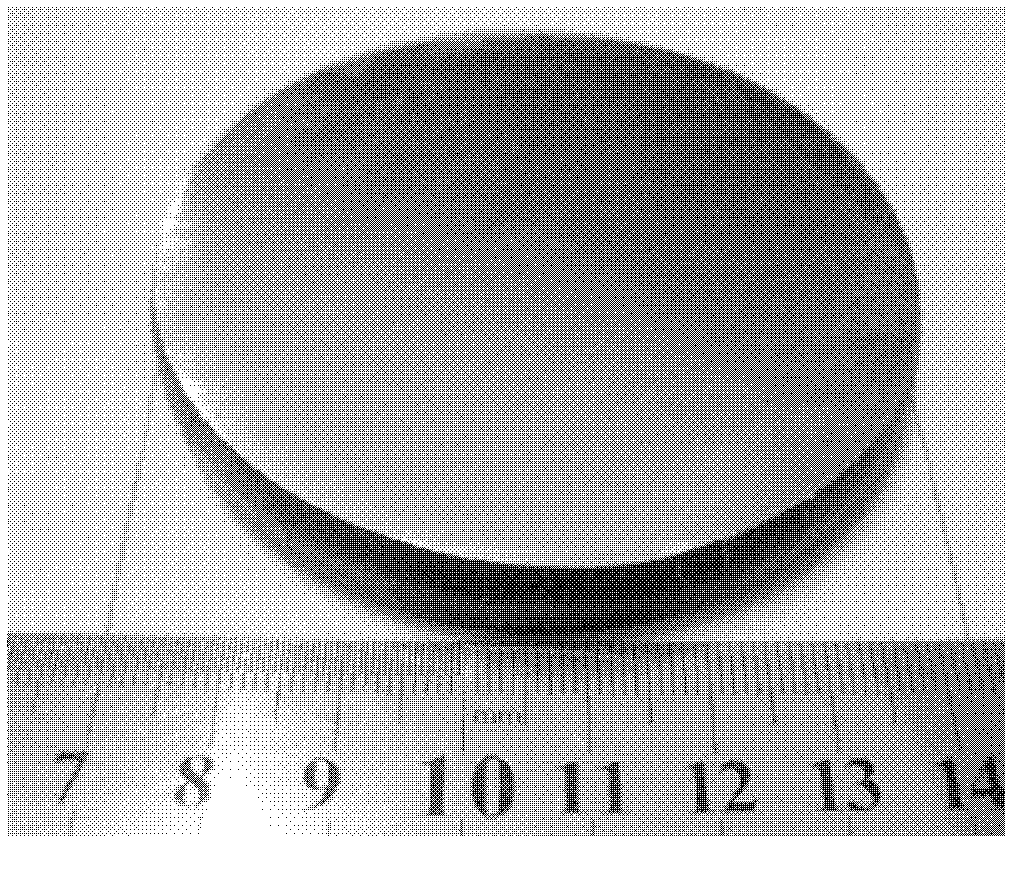

Embodiment 1

[0029]For the magnesium-6% zinc-5% tricalcium phosphate composite material in terms of mass, magnesium powder with a particle size of 75 μm, zinc powder with a particle size of 25 μm, and tricalcium phosphate powder with a particle size of 25 μm are used. The purity of all powders is More than 99.5%, the three powders are weighed on an electronic balance according to the mass ratio according to different use requirements, put into a three-dimensional mixer at room temperature and mix evenly, and the mixing time is 0.5 hours. Put the mixed powder in a mold and press it at room temperature with a pressing pressure of 5Mpa; place the pressed composite material blank in a mold of the same size and specification, pressurize and sinter under a nitrogen protective atmosphere, and first raise the temperature to 400 , keep warm for 5 minutes, then continue to heat up to 650°C, keep warm for 5 minutes. The pressure was kept at 2 MPa throughout the heating process. After the sintering i...

Embodiment 2

[0032] For the composite material whose components are magnesium-1% zinc-1% tricalcium phosphate in terms of mass, magnesium powder with a particle size of 200 μm, zinc powder with a particle size of 150 μm, and tricalcium phosphate powder with a particle size of 75 μm are used. The purity of all powders is at More than 99.5%, the three powders are weighed on an electronic balance according to the mass ratio according to different use requirements, put into a three-dimensional mixer at room temperature and mix evenly, and the mixing time is 2 hours. Put the mixed powder in the mold, press molding at room temperature, and the pressing pressure is 50Mpa; place the pressed composite material blank in the same size mold, pressurize and sinter under nitrogen protection atmosphere, first raise the temperature to 450 , keep warm for 30 minutes, then continue to heat up to 600, keep warm for 30 minutes. The pressure was kept at 20MPa throughout the heating process. After the sinterin...

Embodiment 3

[0035] For the mass-based component of magnesium-15% zinc-30% tricalcium phosphate composite material, use magnesium powder with a particle size of 200 μm, zinc powder with a particle size of 100 μm, and tricalcium phosphate powder with a particle size of 50 μm. The purity of all powders is More than 99.5%, the three powders are weighed on an electronic balance according to the mass ratio according to different usage requirements, put into a three-dimensional mixer at room temperature and mix evenly, and the mixing time is 1 hour. Put the mixed powder in the mold, press molding at room temperature, and the pressing pressure is 40Mpa; place the pressed composite material blank in the same size mold, pressurize and sinter under nitrogen protection atmosphere, and first raise the temperature to 425 , keep warm for 25 minutes, then continue to heat up to 600°C, keep warm for 5 minutes. The pressure was kept at 2 MPa throughout the heating process. After the sintering is completed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com