Sterilization and aldehyde-removal nanometer polyurethane paint

A polyurethane paint, nano-sterilization technology, applied in polyurea/polyurethane coatings, paints containing biocides, coatings, etc., can solve the problems of unenvironmental protection and high price, and achieve good adhesion, good construction, and product adhesion. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific implementation 1:

[0033] The proportion of wear-resistant pre-pulp by weight is 30 parts of alkyd resin, 1.5 parts of defoamer Psalms110, 3.5 parts of cyclohexanone, 4 parts of anti-settling agent 6900-20HV, 52 parts of glass powder VX-SP, 9 parts of butyl acetate and mix well;

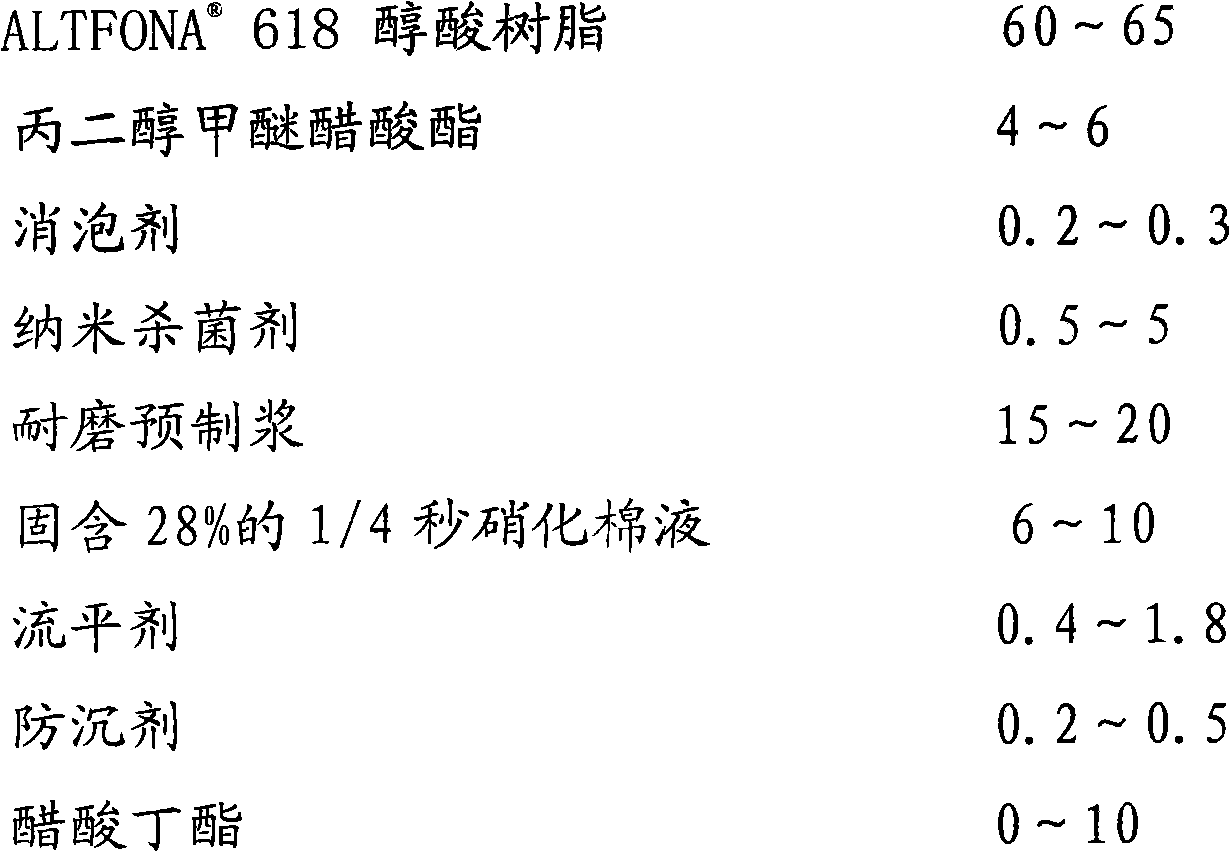

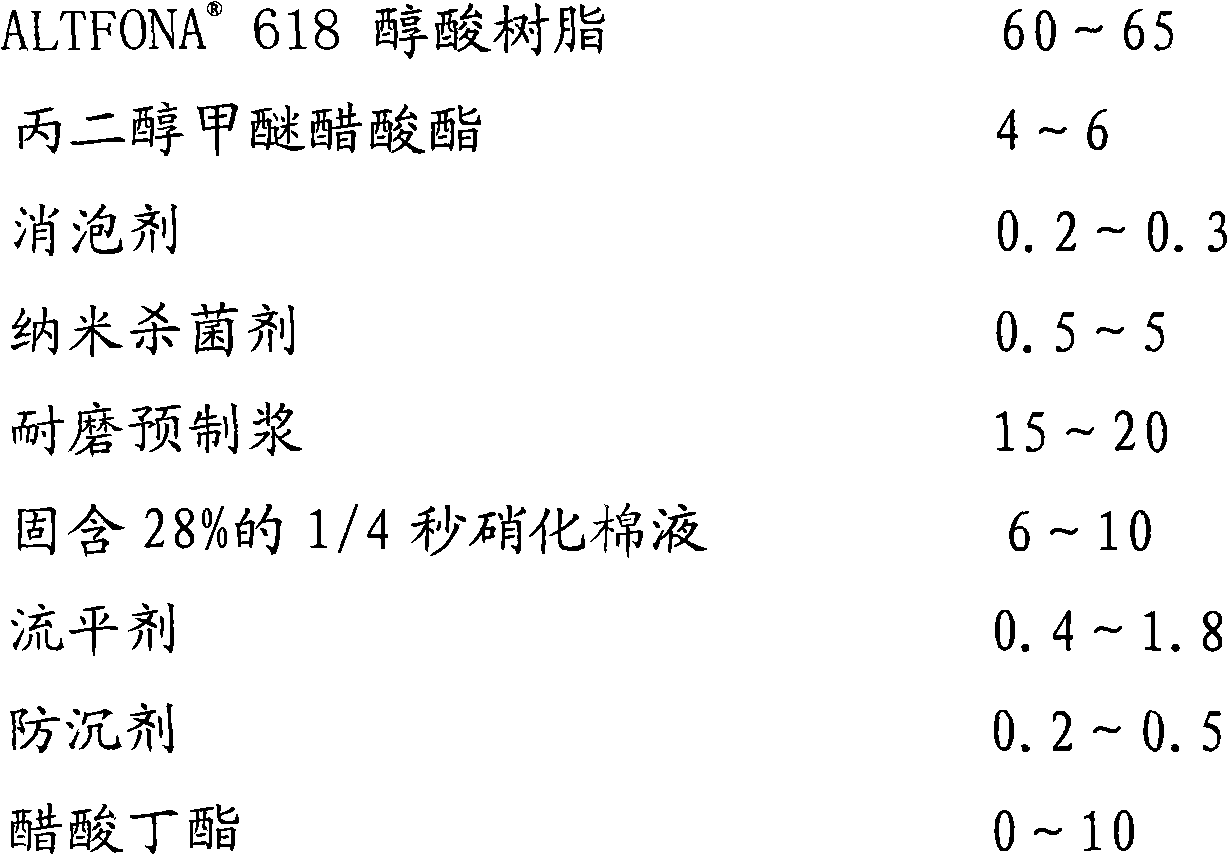

[0034] Component A: Proportioning by weight 62 parts of alkyd resin, 5 parts of propylene glycol methyl ether acetate, 5500.2 parts of defoamer Psalms, 1.5 parts of nano-bactericide super-active nano-silver suspension, and 15 parts of wear-resistant prefabricated pulp are put into the dispersion tank and added with a solid content of 28%. 8 parts of 1 / 4 second nitrocellulose liquid, 0.4 parts of leveling agent BS-2800, 0.3 parts of anti-sedimentation agent 6900-20HV, 7.6 parts of butyl acetate and stir well. After passing the inspection, component A can be made;

[0035] Component B: Mix 28 parts of TDI trimer isocyanate 505N, 42 parts of TDI adduct 530-75N, and 30 parts of butyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com