Anti-shearing polymer and preparation method thereof

A polymer and anti-shear technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problem of increased probability of polymer molecules being sheared and degraded, poor shear resistance of polymers, polymer Reduce oil displacement efficiency and other problems, achieve good injection ability and fluidity control ability, improve viscosification ability, and improve shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Weigh 3.25 grams of the skeleton monomer and 2 grams of maleic anhydride and add them to different beakers respectively, then add 20 grams and 10 grams of dimethyl sulfoxide to stir and dissolve evenly, slowly dissolve the dimethyl sulfoxide solution of the skeleton monomer Add dropwise to the dimethyl sulfoxide solution of maleic anhydride, pass nitrogen gas during the dropwise addition, and place the system in an ice-salt bath, monitor the reaction progress with the pH value, when the pH value of the reaction solution is 4-5 , stop dropping the skeleton monomer solution, continue to stir until the temperature of the reaction liquid system no longer rises, and repeatedly precipitate with chloroform to obtain the functionalized skeleton monomer.

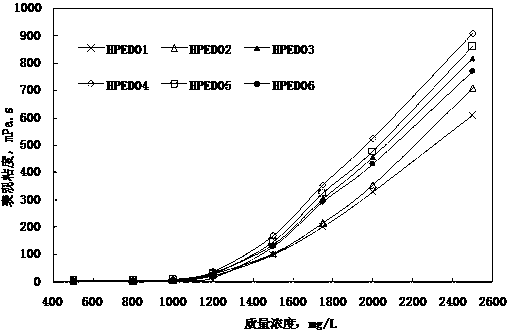

[0044] Weigh 20 grams of acrylamide (AM), 6 grams of acrylic acid (AA), 0.0026 grams, 0.0052 grams, 0.013 grams, 0.026 grams, 0.052 grams, 0.078 grams of functionalized backbone monomers, dimethyl allyl octadecyl Add 0.4 grams...

Embodiment 2

[0046] The functionalized backbone monomer was prepared as in Example 1.

[0047] Weigh 20 grams of acrylamide (AM), 6 grams of acrylic acid (AA), 0.026 grams of functionalized backbone monomers, 0.4 grams, 0.8 grams, 1.2 grams of dimethyl allyl octadecyl ammonium chloride, and 74 grams of distilled water , respectively added to the beaker, stirred and dissolved evenly, adjusted the pH to 6-7 with sodium hydroxide, preheated in a water bath at a temperature of 40°C for 30 minutes, added 0.26 grams each of co-solvent urea and sodium sulfate, chain transfer Agent sodium methoxide 0.052 g, redox initiator sodium bisulfite and ammonium persulfate 4.8 mg each, reacted for 6 hours to obtain three kinds of jelly-like polymers.

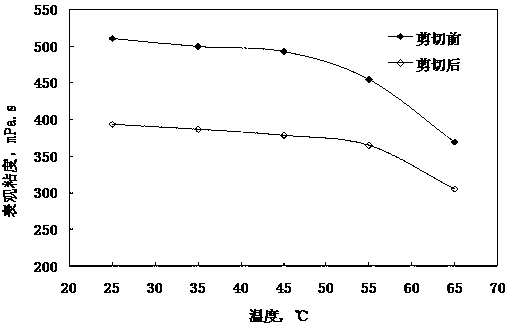

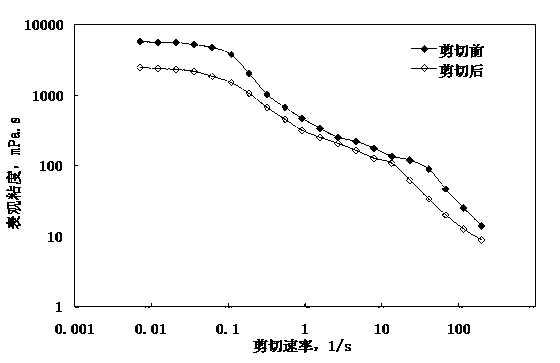

[0048] 2. Performance test of shear resistant polymer

[0049] Take a certain amount of HPED01~HPED06, under the condition of 40℃ water bath, use the salinity of 9374.12mg / L to simulate injection water (the ion composition (unit: mg / L) is: Na + +K + 3091.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com