Production process for preparing ceramsite by using low-grade bauxite

A production process and low-grade technology, applied in the field of ceramsite proppant and its production process, can solve the problems of inability to produce high-strength ceramsite proppant in batches, and overcome low product turnover efficiency, uneven distribution of components, The effect of reducing the breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

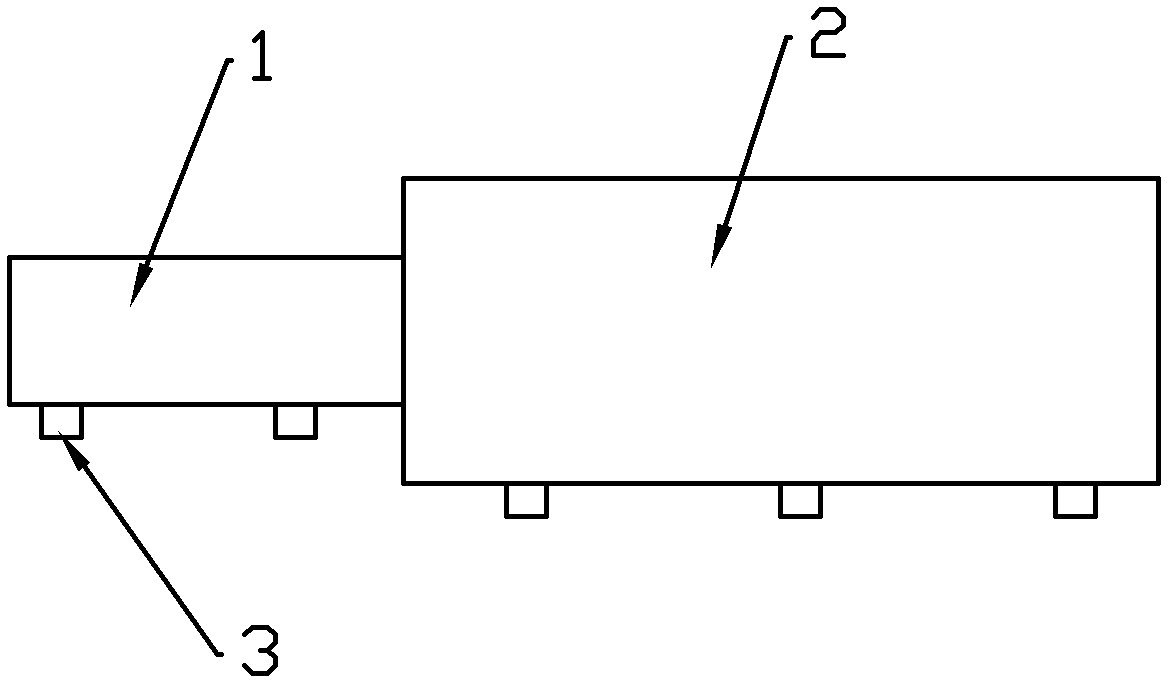

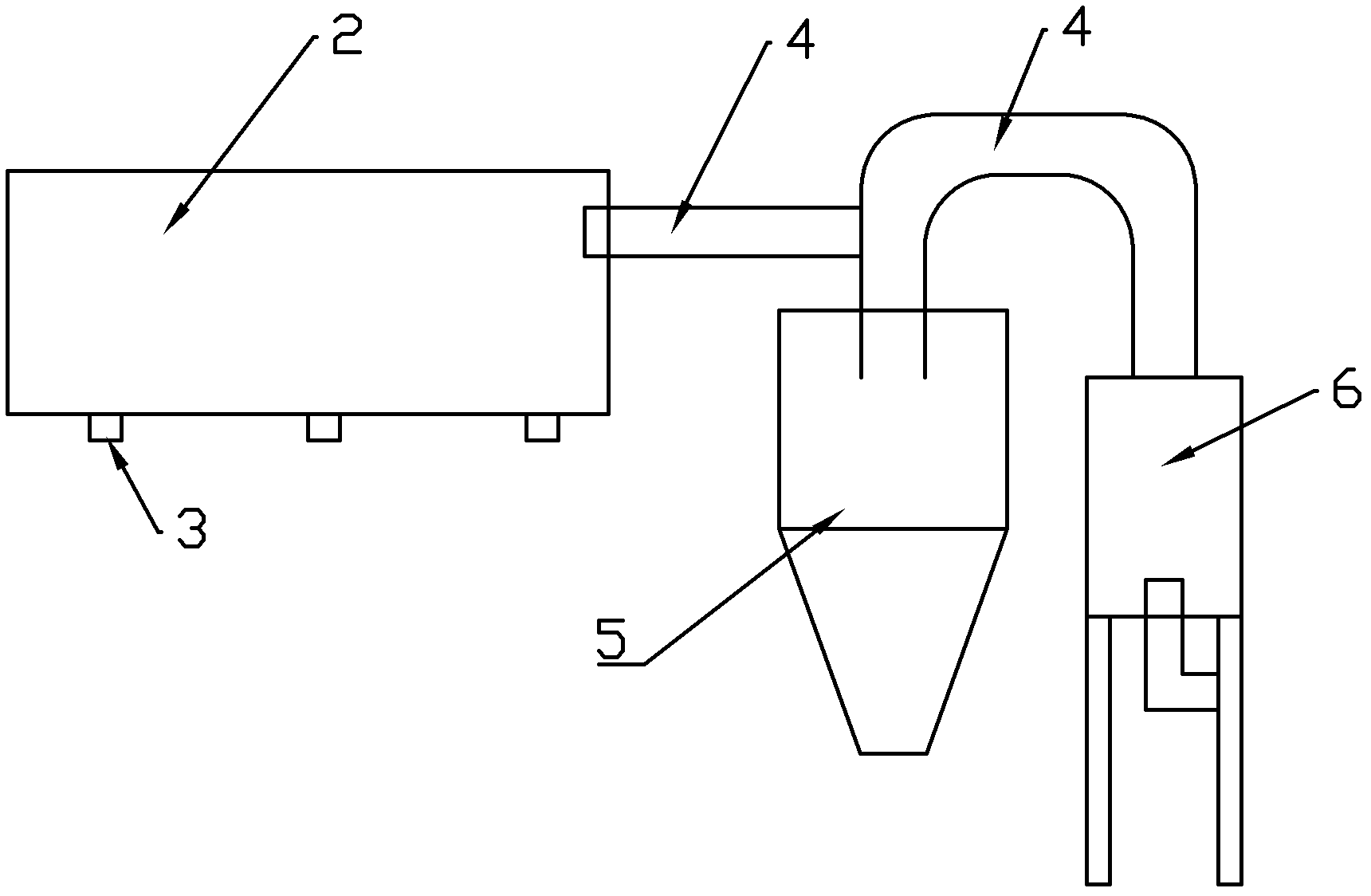

Image

Examples

Embodiment 1

[0033] (1) Ingredients: According to the requirements of the above-mentioned ceramsite proppant ingredients, take low-grade bauxite ore (Al 2 o 3 Content 58%, SiO 2 Content 27%, TiO 2 Content 1.6%) 73 parts, other auxiliary materials are kaolin (Al 2 o 3 Content 35%, SiO 2 content 45%) 15 parts, calcium carbonate (CaO content 52%) 3 parts, talc (SiO 2 Content 60%, MgO content 31%) 4 parts, feldspar (SiO 2 Content 65%, K 2 O, Na 2 O total content 12.5%) 2 parts, titanium concentrate (TiO 2 Content 45%, Fe 2 o 3 Content 28%) 3 parts.

[0034](2) After the low-grade bauxite ore as the main material is crushed into 5mm ore pellets by a jaw crusher, it is mixed with other auxiliary materials to form a mixture. After mixing with the weight ratio of mixture: alumina ball grinding medium: water=1: 2.5: 0.9, add the sodium hexametaphosphate ball milling aid of 0.6% of the mixture quality, place it in the ball mill and wet grind it for 18 hours to become mud, so that The mu...

Embodiment 2

[0040] (1) Ingredients: According to the requirements of the above-mentioned ceramsite proppant ingredients, low-grade bauxite minerals (Al 2 o 3 Content 64%, SiO 2 Content 22%, TiO 2 Content 2.7%) 87 parts, other auxiliary materials are kaolin (Al 2 o 3 Content 33%, SiO 2 content 45%) 7 parts, calcium carbonate (CaO content 52%) 2 parts, talc (SiO 2 Content 57%, MgO content 30%) 1 part, titanium concentrate (TiO 2 Content 52%, Fe 2 o 3 Content 25%) 3 parts.

[0041] (2) The main material, low-grade bauxite ore, is mixed with other auxiliary materials to form a mixture by using a jaw crusher. After mixing with the weight ratio of mixture: alumina ball grinding medium: water=1: 3.0: 1.0, add the sodium hexametaphosphate ball milling aid with a mass ratio of 0.6% of the mixture, and place it in a ball mill for wet grinding for 22 hours to become a slurry. Make the mud particle size reach 8 microns, put it into the mud pool and put it stale; spray and dry the obtained m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Acid solubility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com