Female mold split block assembly of large-scale double punching mold

A technology of concave die and die, applied in the field of large-scale re-blanking die concave die block assembly, can solve the problems of unguaranteed precision, difficult size control, large maintenance workload, etc., to improve work efficiency, low requirements, maintenance handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

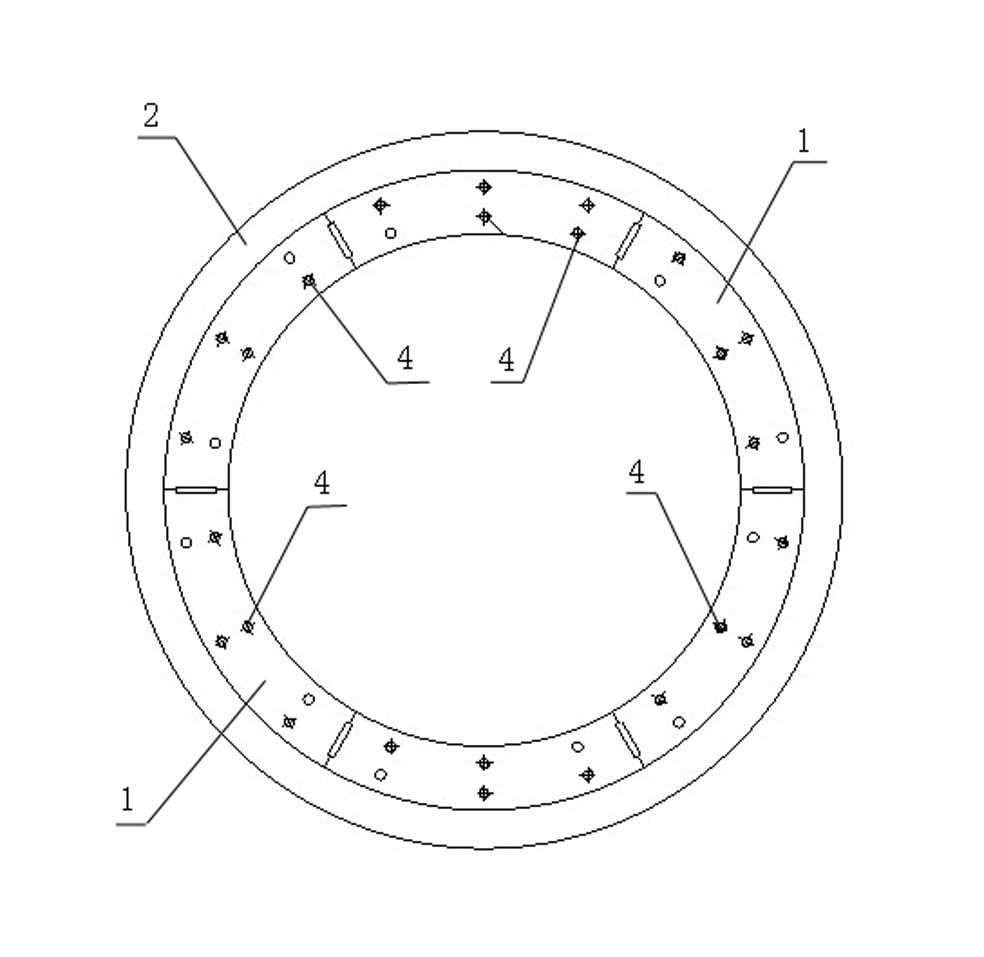

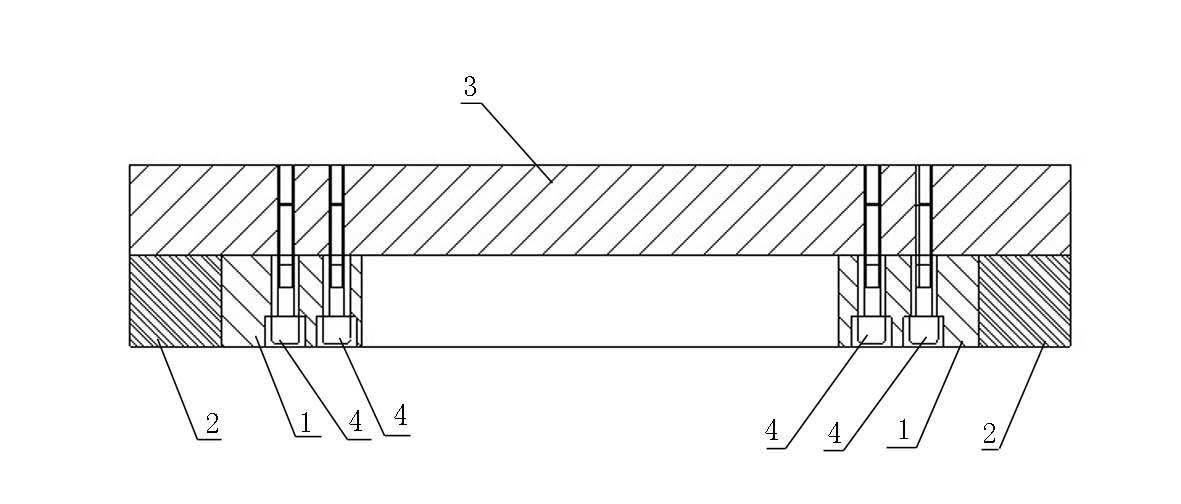

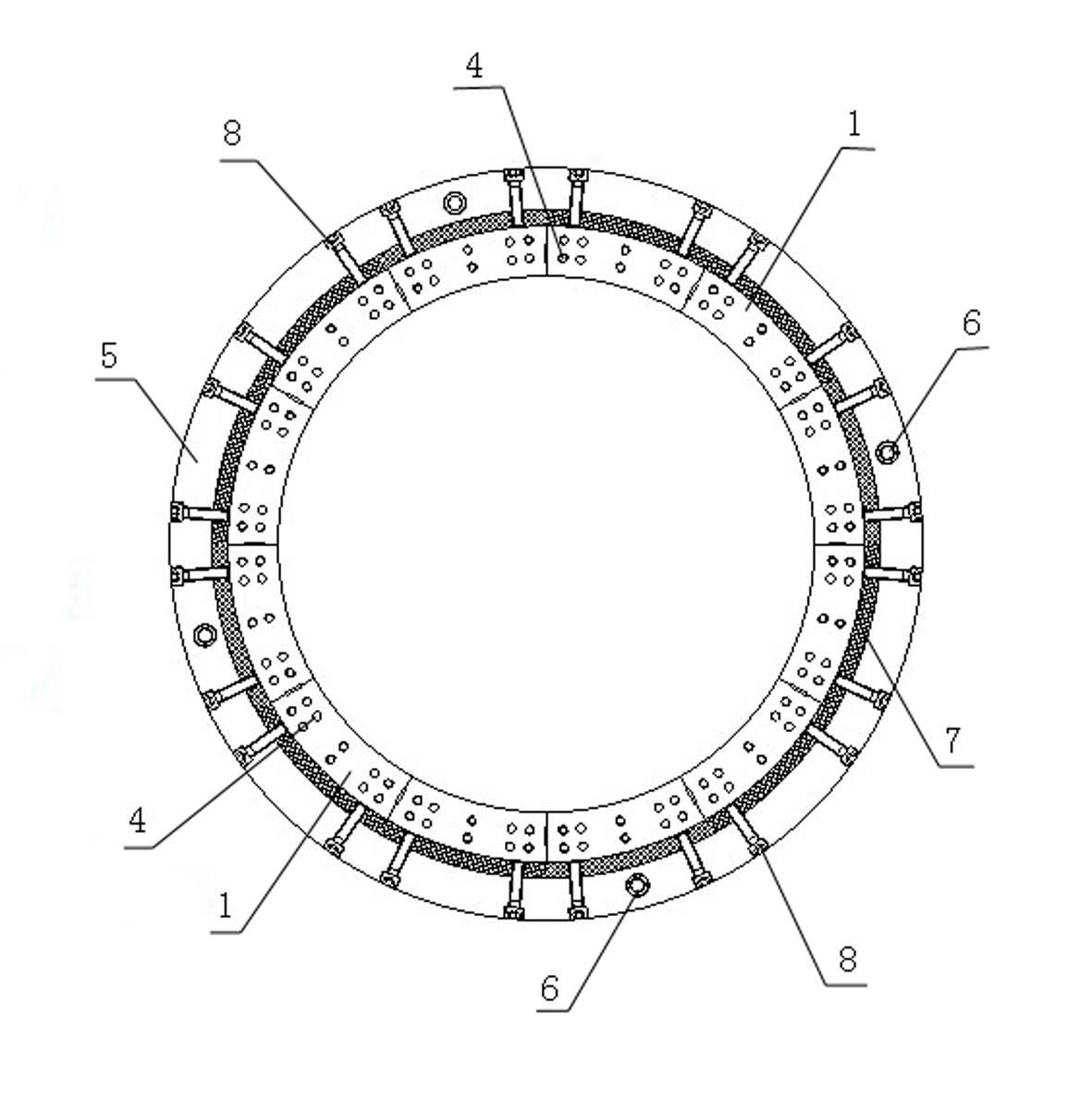

[0014] A large re-punching die die block assembly, including a die block 1 and a fixing device, the fixing device includes a fixing plate 3, and the die block 1 is fixed to the fixing plate 3 by a plurality of screws 4 Above, the fixing device also includes a hoop 5 arranged on the periphery of the die block 1, a low melting point alloy layer 7 arranged between the die block 1 and the hoop 5, and several adjusting screws 8; the hoop 5 is fixed on the fixed plate 3 by several screws 6, and the adjustment screw 8 radially passes through the hoop 5 and the low-melting point alloy layer 7 from the outside to the inside until the screw bottom of the adjustment screw 8 is close to the outer two ends of a single die block 1 .

[0015] The adjusting screw 8 is an inner hexagonal screw, which is convenient for a special tool to be inserted into the inner hexagonal hole of the inner hexagonal screw to adjust the dimensional accuracy of the die block 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com