Machining method of abnormal tubular product for lift control switch

A technology of elevator control and processing method, which is applied in the field of special-shaped pipe processing, can solve the problems of pipe materials that have not been seen in elevator control switches, and achieve the effects of meeting the requirements of industrialized enlarged production, reducing weight and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

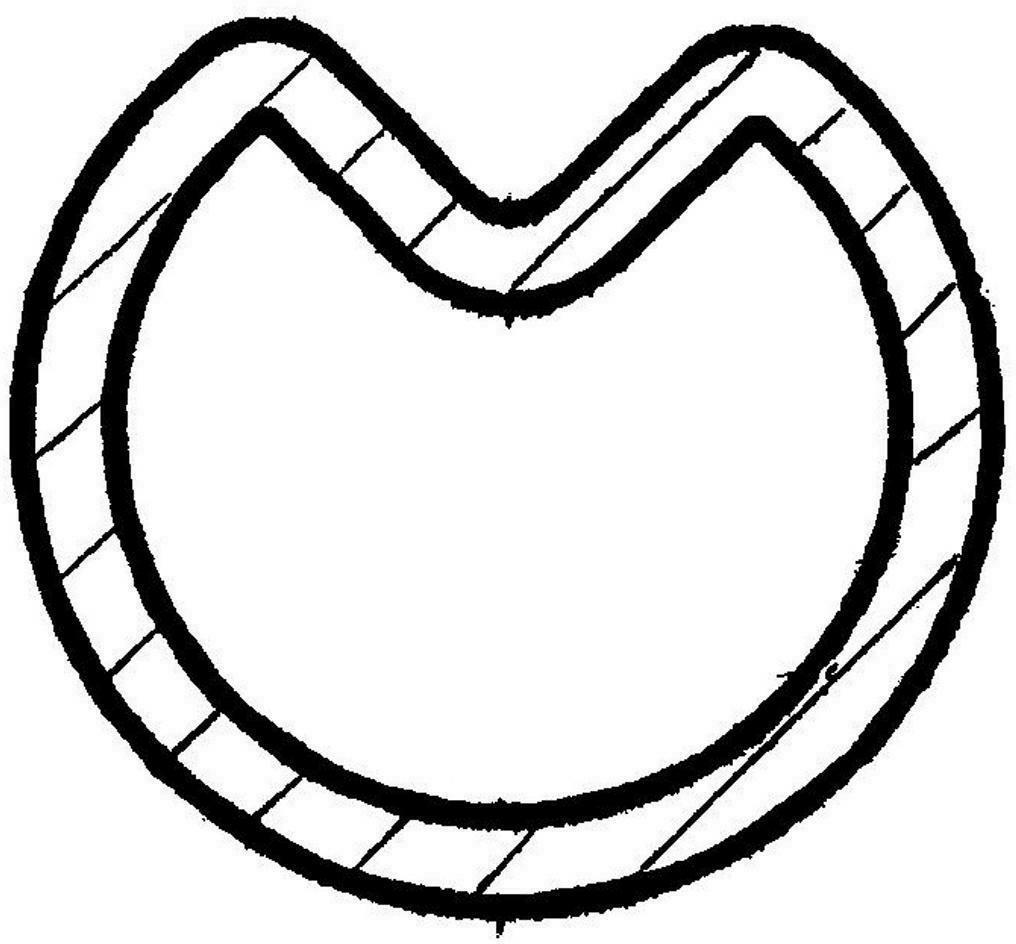

[0032] Take the processing cross-sectional area as 265.5mm 2 and has a shape like figure 1 The shown elevator control switch uses special-shaped pipes as an example.

[0033] ) to prepare materials, first select steel round bars with a diameter of Ф50mm and a grade of No. 20 produced by Jiangsu Huaiyin Iron and Steel Co., Ltd. in this embodiment. The ratio of the cross-sectional area of the steel round bar is 1: 7.39, and the sawing length of the round bar is 820 mm to obtain a round bar blank;

[0034] B) Heating, sending the round billet obtained in step A) into an inclined-bottom heating furnace and heating to 1250°C, and then exiting the inclined-bottom furnace to obtain a round billet to be pierced;

[0035] C) Piercing, lead the round bar blank to be pierced obtained in step B) to a two-roll cross-rolling piercer to perforate into a perforated capillary tube of 51×4 (51mm in outer diameter and 4mm in wall thickness). In this embodiment, The outer diameter of the ...

Embodiment 2

[0045] The figure is sketched, and the processing cross-sectional area is 281.07mm 2 Take special-shaped pipes for elevator control switches as an example.

[0046] ) to prepare materials, first select steel round bars with a diameter of Ф50mm and a grade of No. 20 produced by Jiangsu Huaiyin Iron and Steel Co., Ltd. in this embodiment. The ratio of the cross-sectional area of the steel round bar is 1:7, and the sawing length of the round bar is 820 mm to obtain a round bar billet.

[0024] In a further specific embodiment of the present invention, the lubricating liquid described in step G) is a dilution of lubricant and water, and the weight ratio of lubricant to water is 1:12-16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com