Nanometer fiber lithium ion battery diaphragm material with composite structure and preparation method of nanometer fiber lithium ion battery diaphragm material

A technology of lithium-ion batteries and nanofibers, applied in electronic equipment, structural parts, fiber processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A three-layer nanofiber composite lithium-ion battery membrane material with cellulose non-woven fabric as the middle layer / polymer-ceramic material as the outer layer

[0042] (1) Preparation of electrospinning solution for outer layer material

[0043] Dissolve 80 g of polyvinylidene fluoride (PVDF) in 650 g of N,N-dimethylformamide (DMF) and 276 g of acetone, and stir at a constant temperature of 30°C for 24 hours to obtain a clear and transparent A solution. The mass of PVDF The concentration is 8%; 9 g of silica nanoparticles with a diameter of about 200 nm are added to 100 g of DMF, ultrasonically dispersed for 3 hours, mixed with solution A, and ground at room temperature for 24 hours with a planetary ball mill to obtain a composite spinning solution. The mass of the ceramic material in the composite spinning solution is 40% of the total mass of the polyvinylidene fluoride and the ceramic material.

[0044] (2) Preparation of polymer-ceramic composite nanofibrou...

Embodiment 2

[0049] A three-layer nanofiber composite lithium-ion battery membrane material (PVDF-HFP / PI / PVDF-HFP) with PI non-woven fabric as the middle layer / PVDF-HFP as the outer layer

[0050] (1) Preparation of electrospinning solution for outer layer material

[0051] Dissolve 80 g of vinylidene fluoride-hexafluoropropylene copolymer (PVDF-HFP) in 450 g of DMF and 280 g of acetone, and stir at 30° C. for 24 hours to obtain a clear and transparent A solution.

[0052] (2) Preparation of PVDF-HFP / PI / PVDF-HFP three-layer composite nanofiber lithium-ion battery separator

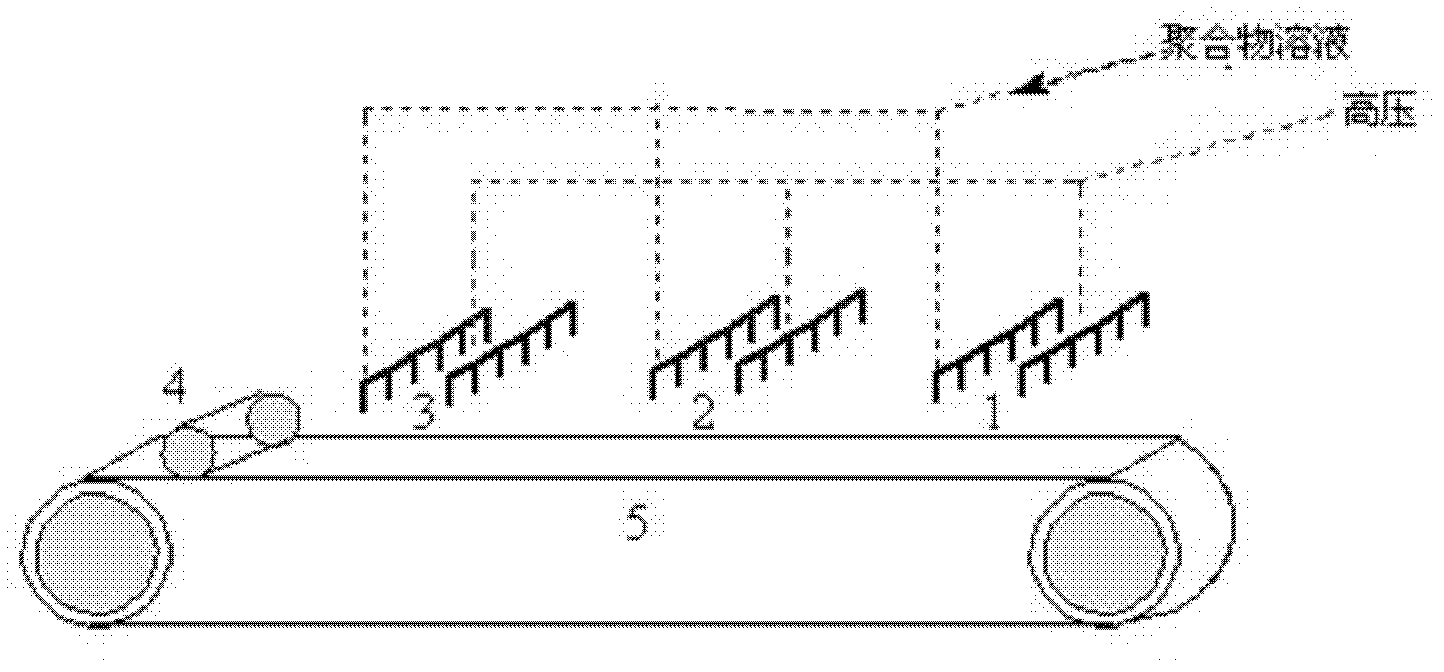

[0053] The PVDF-HFP spinning solution prepared by step (1) is transported to such as attached with a gear pump figure 1 Schematic of a high-flow electrospinning device, the infusion volume is, for example, 9 mL / needle / hour. A DC high voltage such as 24 kV is applied between the nozzle and the conveyor belt. The distance between the nozzle tip and the conveyor belt is set to 10 cm, for example. The nozzle group perf...

Embodiment 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com