Turbocharged corrugated pipe and production process thereof

A technology of turbocharging and production technology, which is applied in the direction of pipes, rigid pipes, pipeline connection layout, etc., can solve the problems of bulky devices, achieve the effect of satisfying functional performance, ensuring appearance quality, and high tearing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

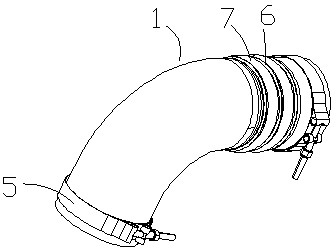

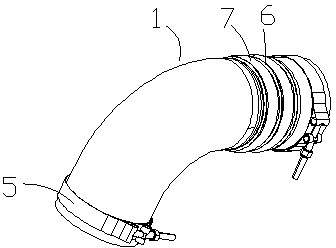

[0029] Figure 1 to Figure 2 Shown are a pipe body 1, an inner pipe rubber layer 2, a fiber thread reinforcement layer 3, an outer pipe rubber layer 4, a metal ring buckle 5, a fixed steel wire 6, and a buffer corrugation 7.

[0030] A turbocharged corrugated pipe, including a pipe body 1, wherein the pipe body 1 is sequentially made of an inner pipe rubber layer 2 made of fluorosilicone rubber material, and a fiber thread reinforcement layer 3 made of aramid thread Nomex from the inside to the outside The outer tube rubber layer made of fluorosilicone rubber material is bonded to form a 4 bonded structure; the two ends of the tube body 1 are crimped and fitted with metal rings 5, and the outer tube rubber layer 4 is surrounded by a fixed steel wire 6.

[0031] In the embodiment, the pipe body 1 is molded with cushioning corrugations 7 for pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com