Smelting process for vanadium titano-magnetite

A technology of vanadium titanomagnetite and smelting method, applied in furnaces, cooking furnaces, furnace types, etc., can solve problems such as direct reduction of vanadium titanomagnetite that is not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

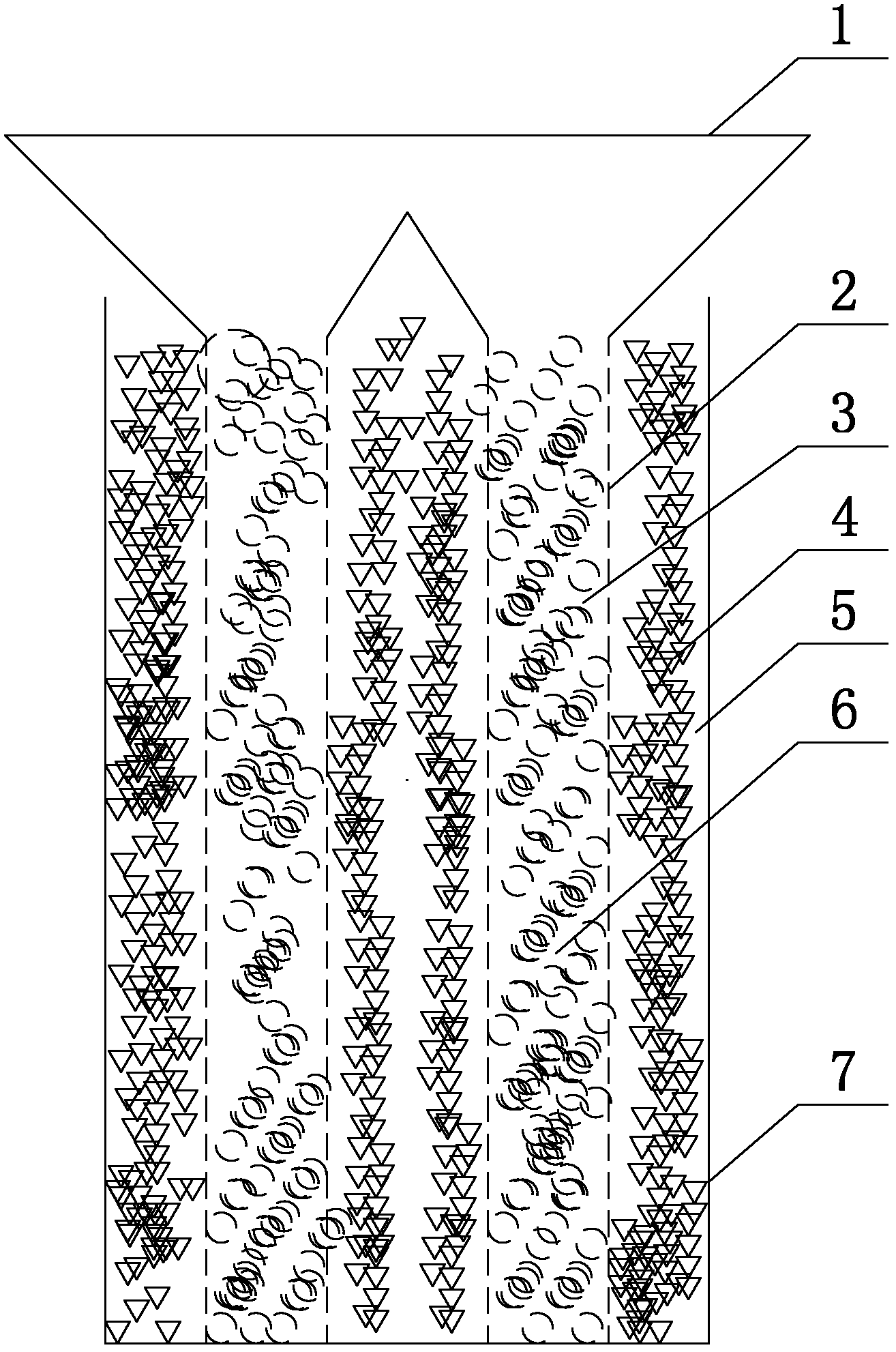

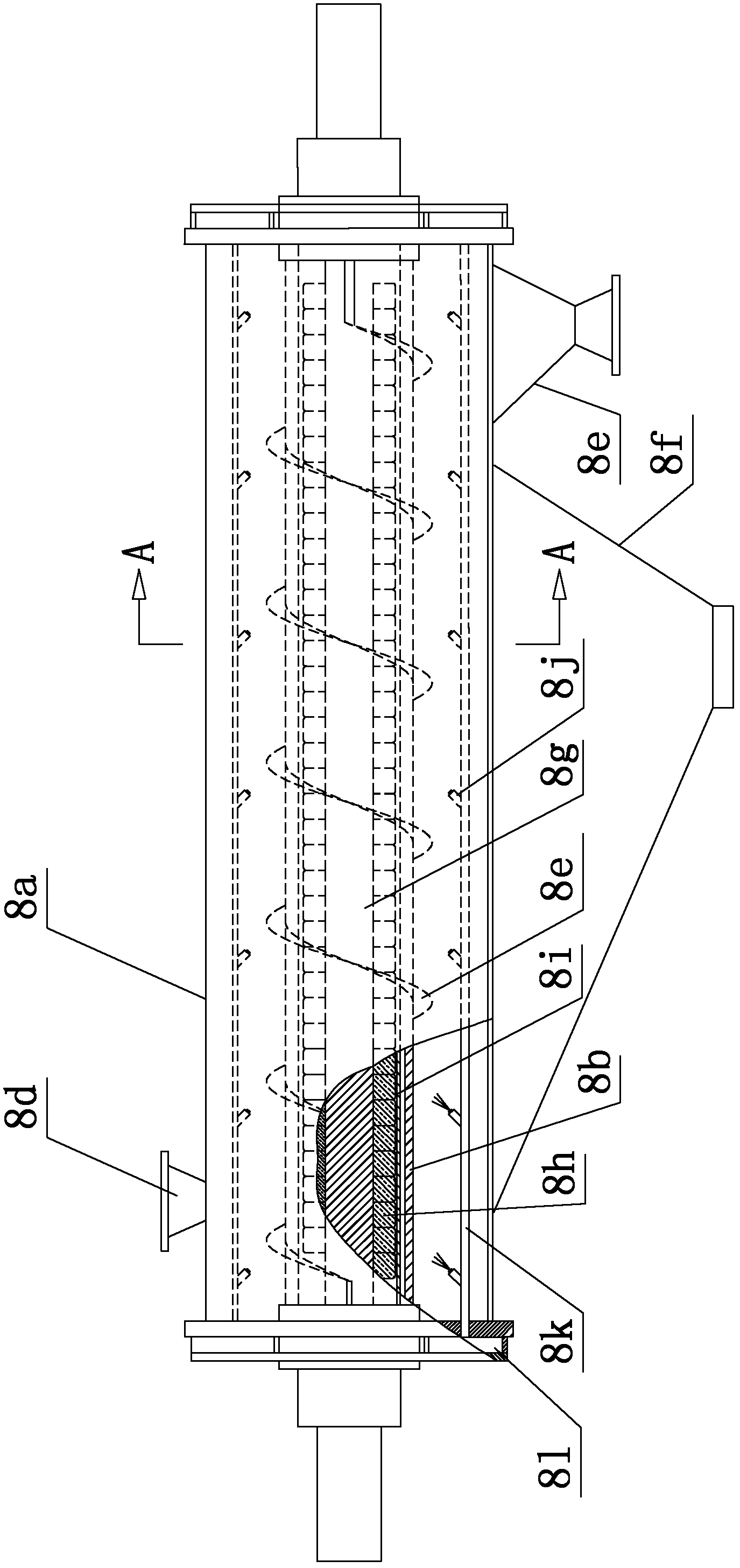

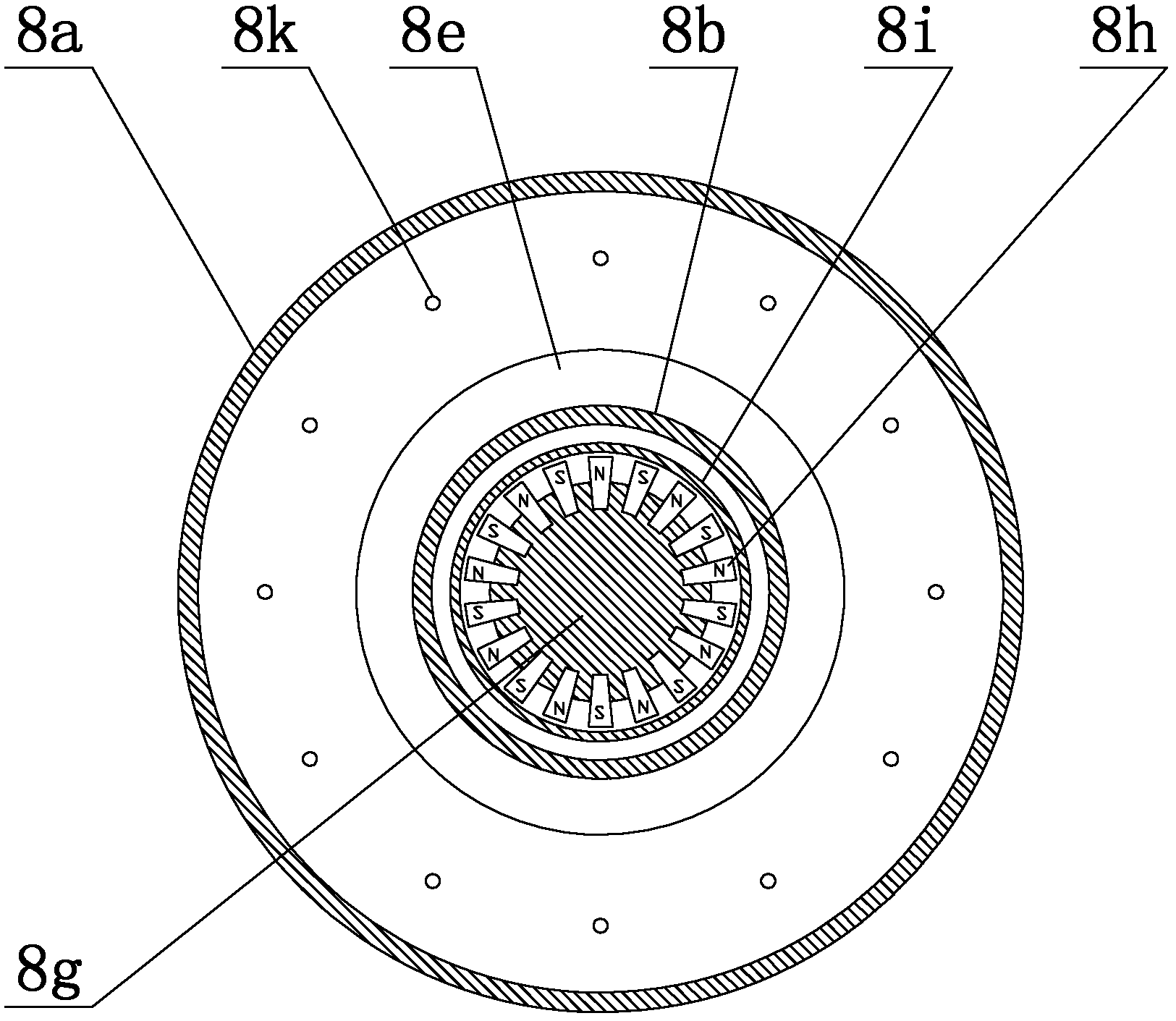

[0032] Take vanadium-titanium magnetite in Panzhihua area, TFe grade is 60.23%, TiO 2 It is 8.64%, and the water content is controlled at 2 It was 35.34%, and the recovery rate was 82.78%. The two materials have respectively reached the quality indicators of iron powder for reducing agent and titanium medium ore, and the recovery rate is also high, realizing the preliminary goal of comprehensive utilization of vanadium-titanium magnetite. Thereafter, the reduced iron powder after the first reduction is subjected to gas-based secondary fine reduction. This reduction method is to use reducing gas and inert gas for reduction under high temperature conditions. The raw material for producing gas is liquid ammonia. Ammonia is decomposed by heating and pyrolysis to generate nitrogen and hydrogen. Nitrogen has relatively stable chemical properties and can be used as a protective gas, while hydrogen can be used as a reducing gas. Of course, the reducing gas can also be produced from na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com