Composite-structure pigment having low lightness and infrared emitting ability and preparation method thereof

A low-infrared emission, composite structure technology, applied in the field of functional materials, can solve the problems of high infrared reflectivity, material brightness reduction, etc., and achieve the effect of low cost and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

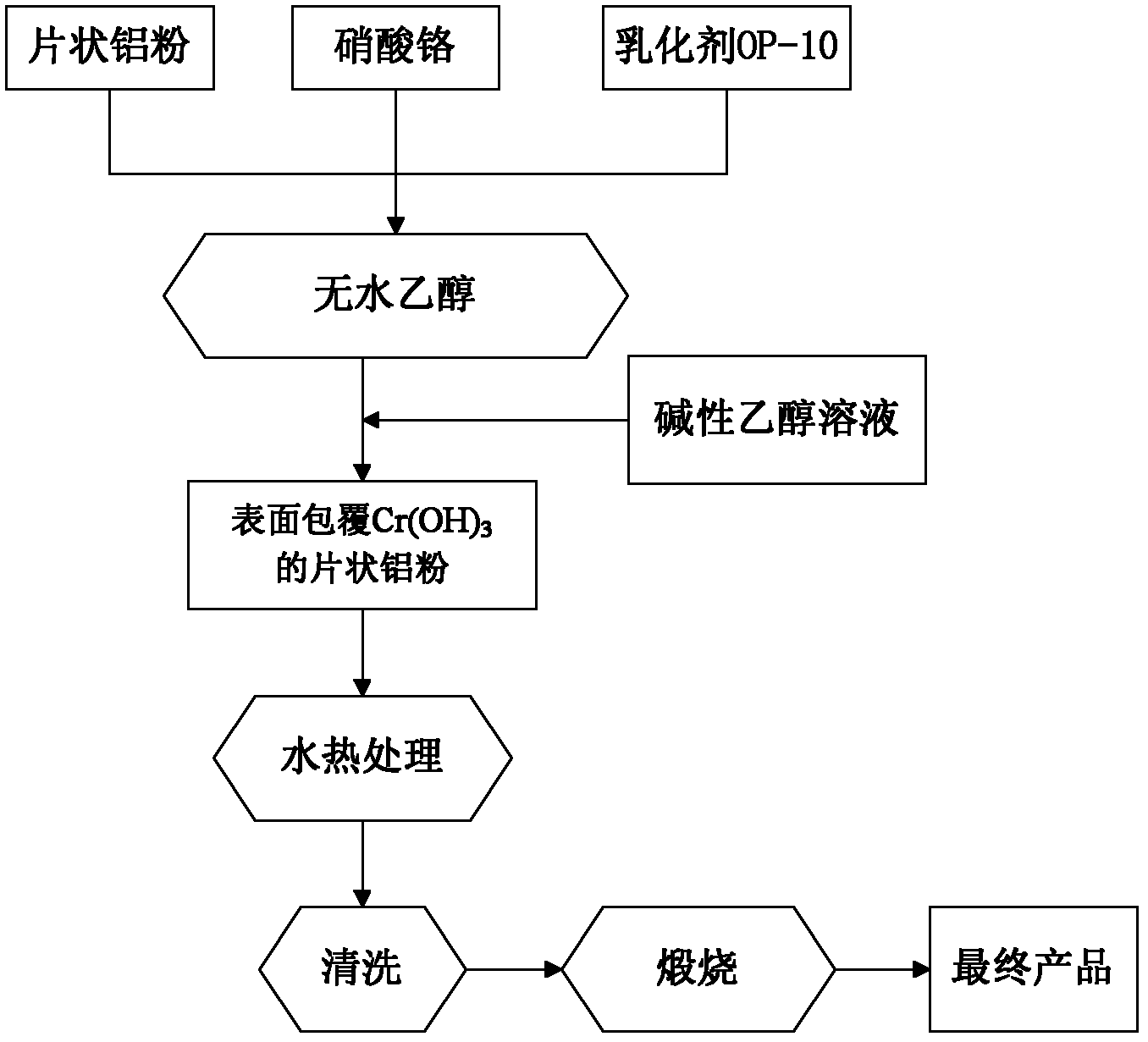

Method used

Image

Examples

Embodiment 1

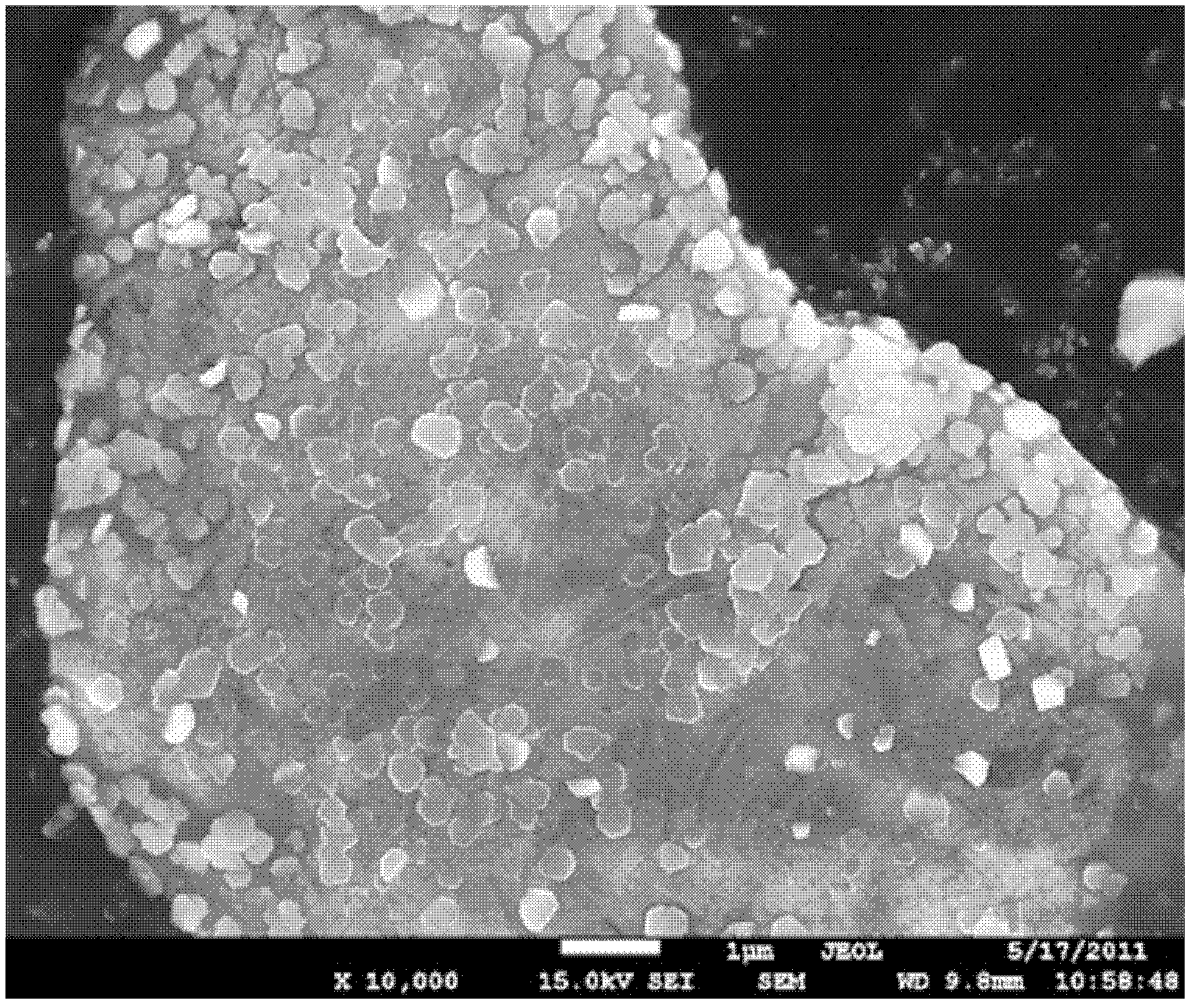

[0031] Weigh clean flake aluminum powder (particle size is 8um) and Cr(NO 3 ) 3 9H 2 O and add emulsifier OP-10 into the Erlenmeyer flask together, inject absolute ethanol, control Cr 3+The ion concentration is 0.07M; ultrasonically disperse the above mixed system, and stir in a constant temperature water bath magnetic stirrer; control the reaction temperature of the mixed system at 60°C, and slowly add ammonia solution diluted with absolute ethanol dropwise to make the pH of the mixed system The value is controlled between 7 and 9; after the reaction is completed, centrifuge the obtained product at 2000r / min for 2 minutes, filter off the supernatant, wash and filter the precipitate, and dry it in a constant temperature drying oven at 50°C After 10 hours, the obtained dry powder was ground with an agate mortar, sieved with a drying net, put into a muffle furnace, and calcined at a temperature of 400-450°C for 2 hours to obtain the final low lightness and low infrared emissiv...

Embodiment 2

[0035] According to Table 2, different molar concentrations of Cr(NO 3 ) 3 9H 2 O ethanol solution, according to Cr(NO 3 ) 3 9H 2 The O:Al molar ratio is 0.1:1. Add clean flake aluminum powder and emulsifier OP-10 into the Erlenmeyer flask; ultrasonically disperse the above mixing system, and stir in a constant temperature water bath magnetic stirrer; control the mixing The reaction temperature of the system is 60°C, and the ammonia solution diluted with absolute ethanol is slowly added dropwise, so that the pH value of the mixed system is controlled between 7 and 9; Centrifuge for 2 minutes, filter off the supernatant, wash and filter the sediment, and dry in a constant temperature drying oven at 50°C for 10 hours. The obtained dry powder is ground with an agate mortar, sieved with a drying net, and then put into a muffle furnace , calcined at a constant temperature of 400-450° C. for 2 hours to obtain the final composite structural pigment with low lightness and low inf...

Embodiment 3

[0039] According to Table 3, clean flaky aluminum powders with different particle sizes were selected, according to Al:Cr(NO 3 ) 3 9H 2 Al:Cr(NO 3 ) 3 9H 2 O ethanol solution, and add emulsifier OP-10 into the Erlenmeyer flask configuration solution, control Cr 3+ The ion concentration is 0.07M; ultrasonically disperse the above mixed system, put it into a constant temperature water bath magnetic stirrer; control the reaction temperature of the mixed system at 60°C, and slowly add ammonia solution diluted with absolute ethanol dropwise to make the pH of the mixed system The value is controlled between 7 and 9; after the reaction is completed, centrifuge the obtained product at 2000r / min for 2 minutes, filter off the supernatant, wash and filter the precipitate, and dry it in a constant temperature drying oven at 50°C After 10 hours, the obtained dry powder was ground with an agate mortar, sieved with a drying net, put into a muffle furnace, and calcined at a constant temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com