A kind of black heat reflection pigment and its preparation method and application

A technology of heat-reflective pigments and black, applied in the direction of reflection/signal coatings, etc., can solve the problems of not meeting the requirements of heat-reflective pigments, increased production costs, expensive precursor raw materials, etc., and achieve low raw material costs, less equipment investment, near-infrared The effect of high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

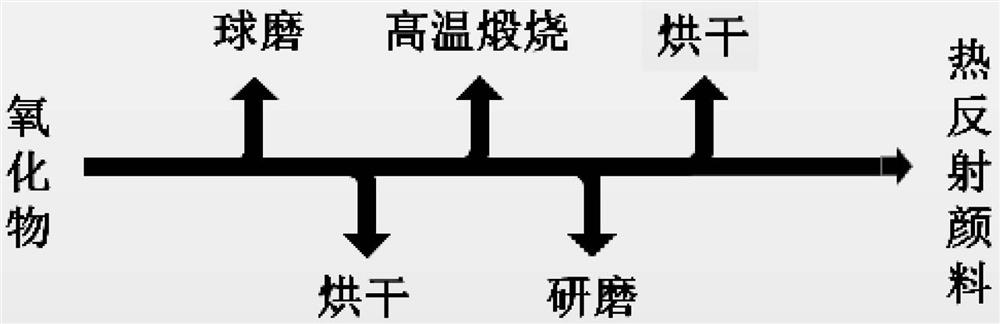

Method used

Image

Examples

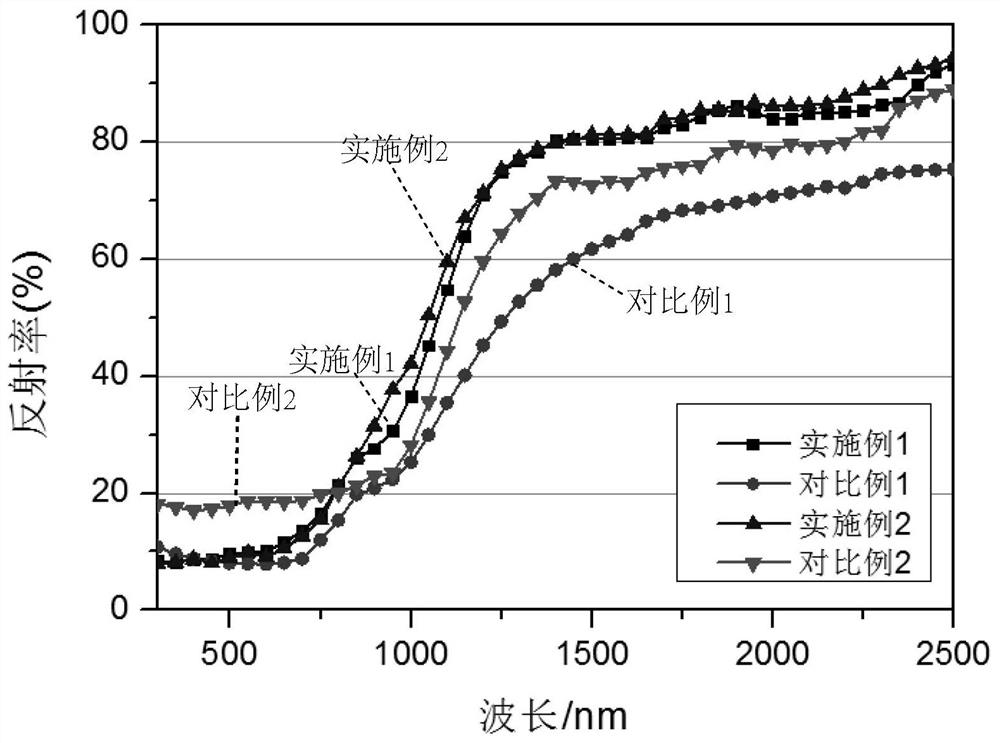

Embodiment 1

[0040] ZnO, CuO, Al 2 o 3 and Cr 2 o 3 According to the stoichiometric relationship Zn 1-x Cu x al 2-y Cr y o 4 Mixing where x=0.4, y=0.4. Add water and grinding balls to the mixed oxide, the mass ratio of the mixed oxide, water and grinding balls is 1:1:3, repeat at 400r / min, and ball mill for 3h to get the slurry; then put the slurry into the oven Medium drying, drying temperature is 90°C, drying time is 8h, to obtain a powder; then the obtained powder is ground and put into a muffle furnace for calcination, and the temperature is raised from room temperature in an air atmosphere, and the heating rate is 5 °C / min, heat up to 900 °C, keep warm for 8 hours, then cool down to room temperature at a cooling rate of 5 °C / min to obtain a calcined pigment sample, then ball mill the obtained sample at 400 r / min for 4 hours, and dry at 90 °C for 8 hours. Finally, a black heat-reflecting pigment was obtained with an average particle diameter of 1.2 μm.

Embodiment 2

[0042] ZnO, CuO, Al 2 o 3 and Cr 2 o 3 According to the stoichiometric relationship Zn 1-x Cu x al 2-y Cr y o 4 Mixing where x=0.5, y=0.3. Add water and grinding balls to the mixed oxide, the mass ratio of mixed oxide, water and grinding balls is 1:2:5, repeat at 300r / min, and ball mill for 4h to get the slurry; then put the slurry into the oven Medium drying, the drying temperature is 80°C, the drying time is 12h, and the powder is obtained; then the obtained powder is ground and put into a muffle furnace for calcination, and the temperature is raised from room temperature in an air atmosphere, and the heating rate is 5 °C / min, heat up to 1000 °C, keep it warm for 7 hours, and then cool down to room temperature at a cooling rate of 10 °C / min to obtain a calcined pigment sample, then ball mill the obtained sample at 500 r / min for 4 hours, and dry at 80 °C for 12 hours. Finally, a black heat-reflecting pigment was obtained with an average particle diameter of 1.5 μm. ...

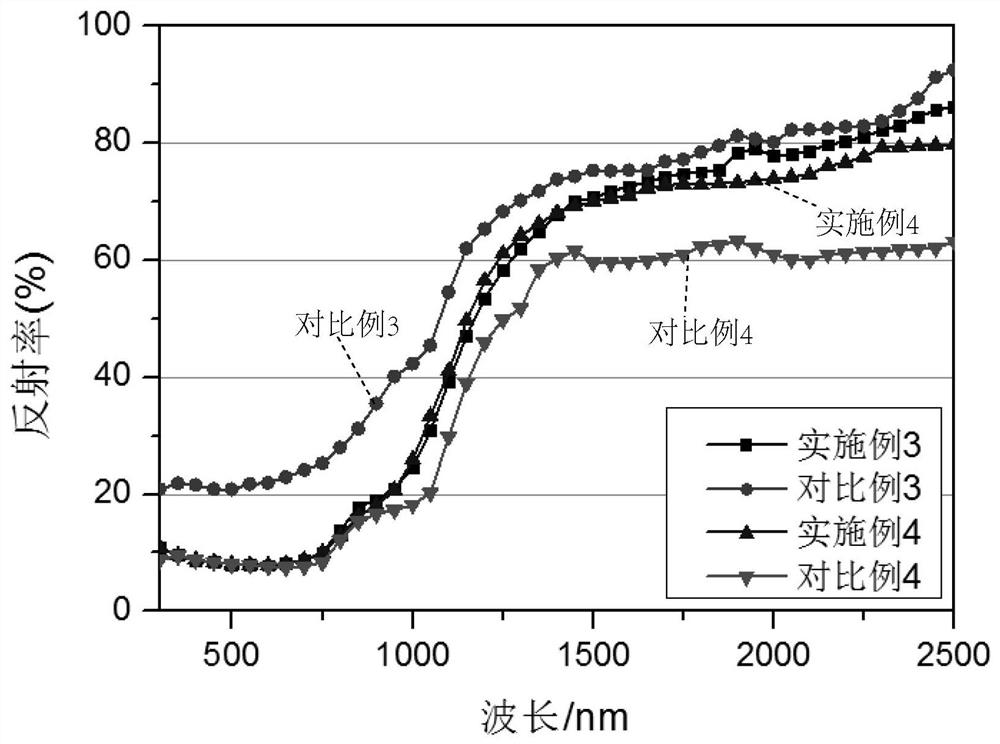

Embodiment 3

[0044] ZnO, CuO, Al 2 o 3 and Cr 2 o 3 According to the stoichiometric relationship Zn 1-x Cu x al 2-y Cr y o 4 Mixed, where x=0.7, y=0.2. Add water and grinding balls to the mixed oxide, the mass ratio of mixed oxide, water and grinding balls is 2:3:9, repeat at 600r / min, ball mill for 2h to get the slurry; then put the slurry into the oven Medium drying, the drying temperature is 70°C, the drying time is 14h, and the powder is obtained; then the obtained powder is ground and put into a muffle furnace for calcination, and the temperature is raised from room temperature in an air atmosphere, and the heating rate is 8 °C / min, heat up to 1100°C, keep it warm for 6h, then cool down to room temperature at a cooling rate of 10°C / min to obtain a calcined pigment sample, then ball mill the obtained sample at 600r / min for 3h, and dry at 80°C for 12h. Finally, a black heat-reflecting pigment was obtained with an average particle diameter of 0.9 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com