Method for preparing polyoxyethylene fatty alcohol ether-siloxane copolymer

A technology of alcohol polyoxyethyl ether and polysiloxane is applied in the field of non-ionic silicone emulsifier to achieve the effects of simple method, good compatibility and emollient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

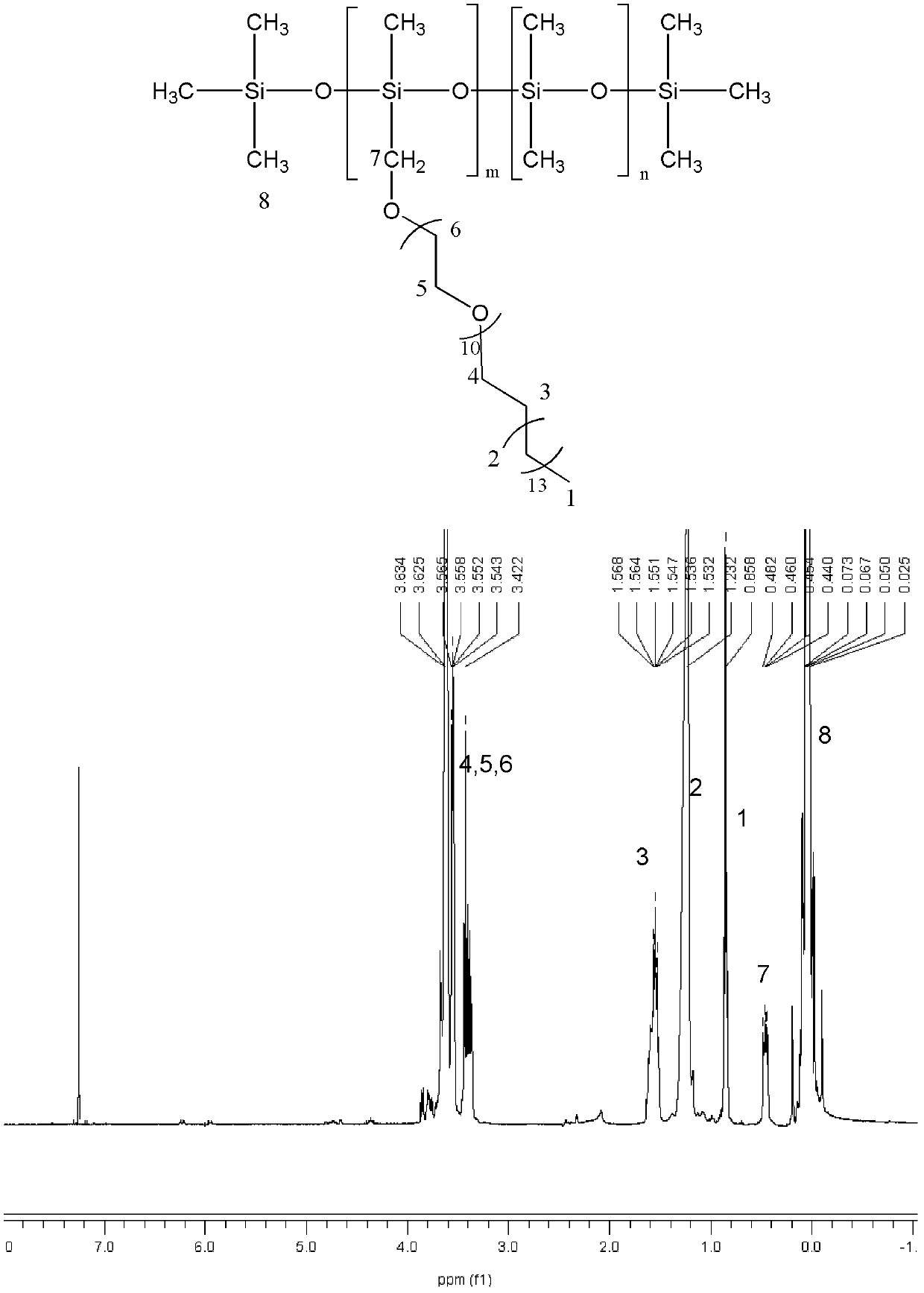

[0046] Preparation of cetyl polyoxyethyl ether polysiloxane:

[0047] 1) under nitrogen protection, 34g hexadecyl decapolyoxyethyl alcohol C 16 h 33 O(CH 2 CH 2 O) 10 Add OH to a 250mL four-neck flask with a stirring reflux water separator, add 2.4g NaOH, and react at 130°C with 100mL toluene as a solvent. Hexadecyl polyoxyethylene sodium salt, then add propylene chloride dropwise and react at 50°C for 12 hours. The product is centrifuged to separate sodium chloride and unreacted sodium hydroxide, and the solvent and low boiling matter are removed under reduced pressure to obtain terminal allyl Hexadecyl polyoxyethyl ether intermediate. Its terminal double bond content is 95.2%.

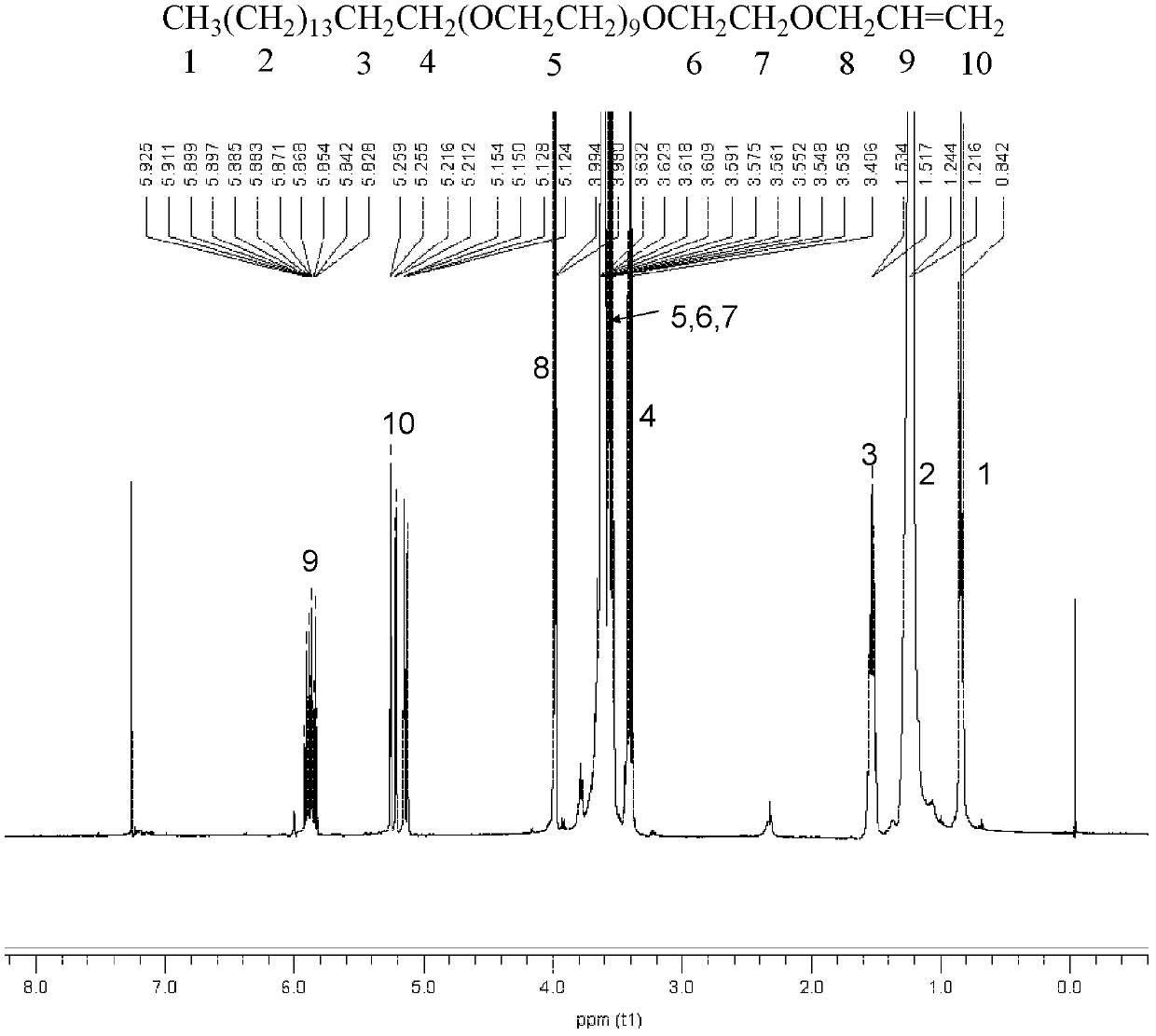

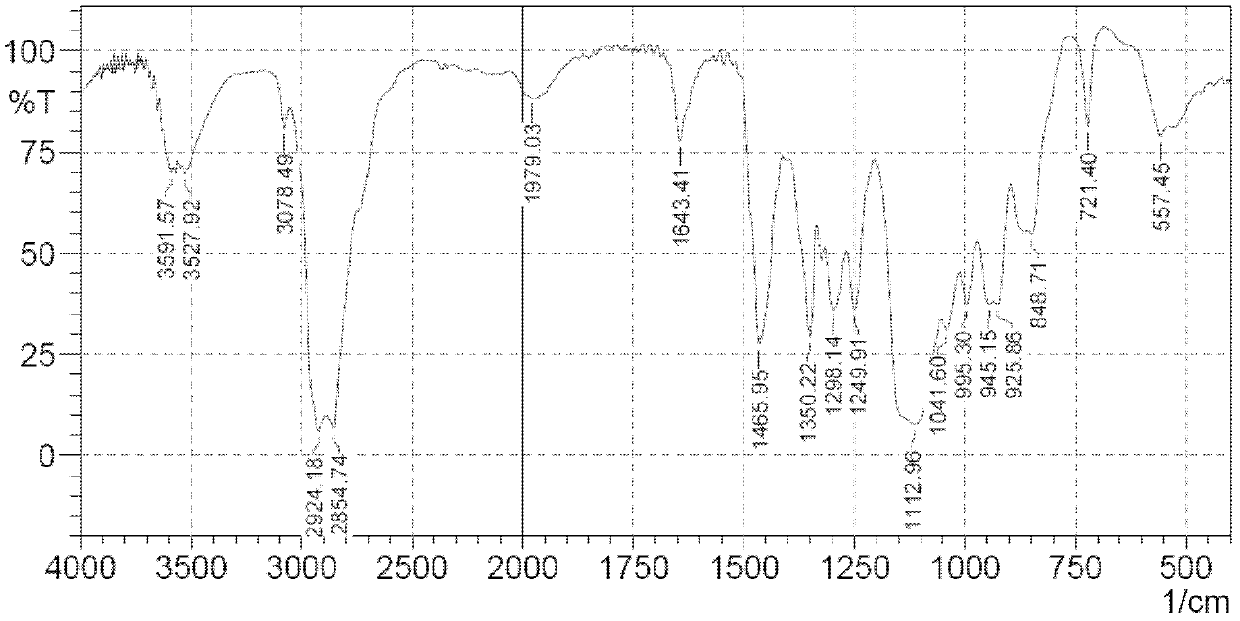

[0048] figure 1 Is the terminal allyl hexadecyl polyoxyethyl ether intermediate nuclear magnetic spectrum, in the figure 1 H NMR (400MHz, CDCl 3 )(δppm): 0.84(t, 3H, CH 3 CH 2 -); 1.22(m, 26H, CH(CH 2 ) 13 -); 1.53(m, 2H, -(CH 2 ) 13 CH 2 CH 2 O-); 3.41(t, 2H, -(CH 2 ) 13 CH 2 CH ...

Embodiment 2

[0054] The preparation process of the fatty alcohol polyoxyethyl ether polysiloxane in this example is the same as in Example 1, and without changing other conditions in Example 1, only 40 g of low hydrogen-containing silicone oil (0.1% hydrogen content) is changed to low Hydrogen silicone oil (0.18% hydrogen content) 22.22g.

Embodiment 3

[0056] 1) Under nitrogen protection, 24.5g hexadecyl (polyoxyethyl) 6 Alcohol C 16 h 33 O(CH 2 CH 2 O) 6 Add OH to a 250mL four-neck flask with a stirring reflux water separator, add 2.4g NaOH, and react at 130°C with 100mL toluene as a solvent. Hexadecyl polyoxyethylene sodium salt, then add propylene chloride dropwise and react at 50°C for 12 hours. The product is centrifuged to separate sodium chloride and unreacted sodium hydroxide, and the solvent and low boiling matter are removed under reduced pressure to obtain terminal allyl Hexadecyl polyoxyethyl ether intermediate.

[0057] 2) Under the protection of nitrogen, add 21.2 g of the allyl cetyl polyoxyethyl ether intermediate obtained in step 1) and 40 g of low hydrogen-containing silicone oil (0.1% hydrogen content) into the four-port Add 20 mL of toluene to the flask, heat up to 90° C., and add 80 mg of 0.3% chloroplatinic acid in isopropanol. The reaction was initially exothermic, and the reaction was carried o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com