Monolithic catalyst for low temperature oxidation of methane and preparation thereof

A monolithic catalyst, oxidation reaction technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as explosion hazards, achieve low cost, raw materials The effect of rich and good catalytic oxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

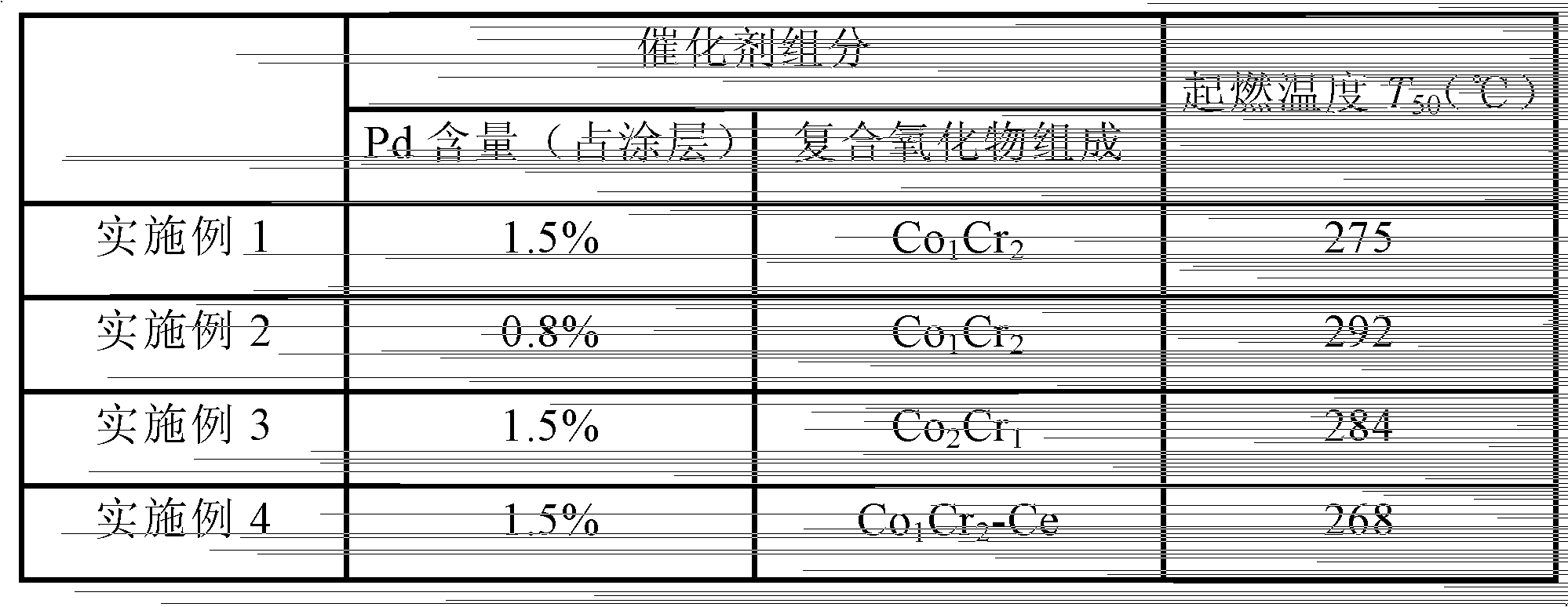

Examples

Embodiment 1

[0029] 25.648g Co(NO 3 )2 ·6H 2 O and 70.536g Cr(NO 3 ) 3 9H 2 O was dissolved in 200mL deionized water to obtain a cobalt-chromium salt solution, in which [Co 2+ ]: [Cr 3+ ]=1:2, [Co 2+ ]+[Cr 3+ ]=1.32mol / L; under vigorous stirring, dropwise add the above-mentioned saline solution with 10wt.% ammonia solution until the mixed solution pH=9.0, then age under stirring; vacuum filter, and wash with deionized water for 3 times, and then dried at 110°C, followed by sintering at 500°C for 2 hours to obtain the composite metal oxide Co 1 Cr 2 ;

[0030] 50g γ-Al 2 o 3 and 5.5g oxide Co 1 Cr 2 Put it into a beaker, add 140g deionized water, and stir at room temperature for 0.5h; ball mill the suspension to control the particle size D 90 =30μm, to obtain a slurry; then add 8.5g Pd(NO 3 ) 2 (the mass fraction of Pd is 10%), wherein the addition of Pd accounts for about 1.5% of catalyst coating weight, finally adjusts pH at 4 with nitric acid, obtains coating slurry;

[...

Embodiment 2

[0033] Preparation method is the same as embodiment 1, and difference is to add 4.5g Pd (NO 3 ) 2 (the mass fraction of Pd is about 10%), wherein the addition of Pd accounts for about 0.8% of the weight of the catalyst coating, and the catalyst 2 of the present invention is obtained.

Embodiment 3

[0035] The preparation method is the same as in Example 1, except that in the salt solution, 49.791g Co(NO 3 ) 2 ·6H 2 O and 34.230g Cr(NO 3 ) 3 9H 2 O was dissolved in 200mL deionized water to obtain a cobalt-chromium salt solution, in which [Co 2+ ]: [Cr 3+ ]=2:1, the catalyst 3 of the present invention was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com