Power supplying circuit and power supplying method for chain-type SVG (static var generator) modules

A power supply circuit and chain technology, applied in circuit devices, electrical components, electromagnetic wave systems, etc., can solve the problems of low feasibility, limited space of unit modules, high cost, wide adjustable range, mature insulation technology, and simple production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

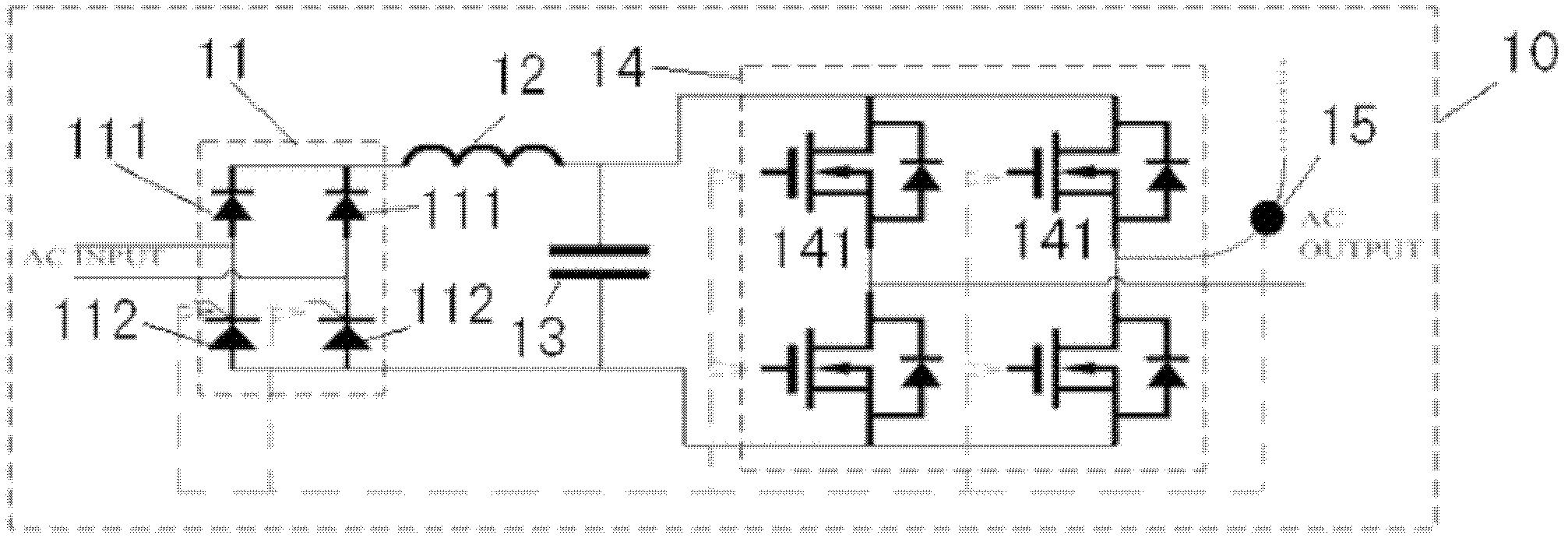

[0014] Such as figure 1 As shown, the present invention provides a power supply circuit for a chained SVG (static var generator) module in series, which includes an AC constant current control power supply 10, several current sensing receiving circuits 20 and high-voltage cables 30, each Each current induction receiving circuit 20 is composed of a ferrite magnetic ring 21 and a coil 22 wound on the ferrite magnetic ring 21 . The output end of the AC constant current control power supply 10 is connected to a high-voltage cable 30, and the high-voltage cable 30 is passed through the ferrite magnetic ring 21 of each current induction receiving circuit 20, so that each ferrite magnetic ring 21 forms a series structure. Wherein, the input terminals of each SVG module are respectively connected to the output terminals of the current sensing receiving circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com