Insulating operating bar applied to lead lapping of 10kV distribution network

A technology of insulating operating rods and splicing leads, which is applied in the field of distribution network, can solve the problems of temporary slapping heads falling off, and achieves the effects of convenient splicing operations, reducing splicing work and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

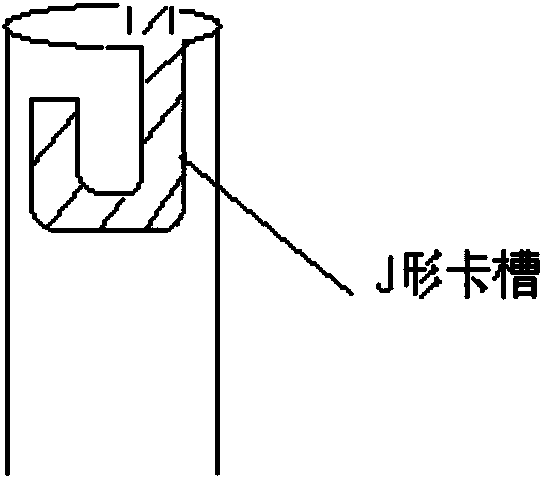

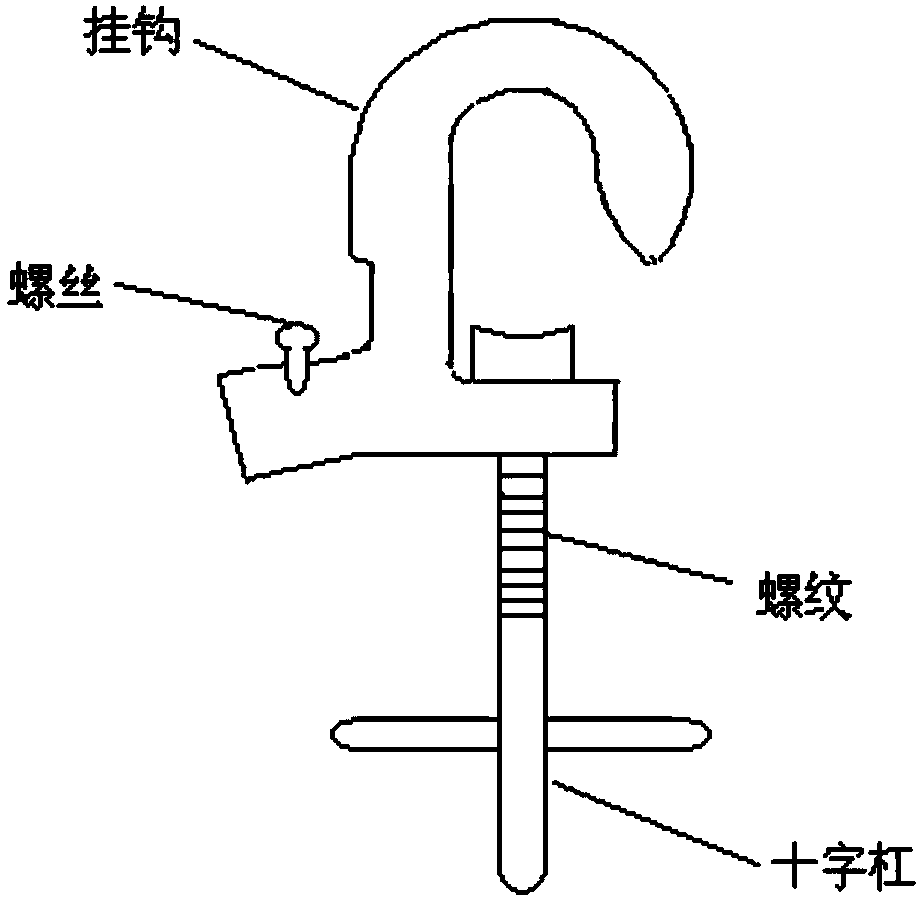

[0016] The insulating operating rod of the present invention is used for operating the temporary lap joints, so as to realize the work of lap joint lead wires in rainy days. Such as figure 1 As shown, the insulating operating rod is a hollow cylindrical cross lock insulating operating rod, an elastic device is arranged in the hollow body of the insulating operating rod along the axial direction, and the two sides of the insulating operating rod are symmetrical There are two J-shaped slots, the longer side of the J-shaped slot communicates with the top of the insulating operating rod, and the insulating operating rod is connected to the temporary lap for the lead wire through the J-shaped slot. The head is connected, and one end of the temporary head connected to the insulating operation rod is a cross-shaped structure, and the temporary head forms a cross-lock structure through the cross-shaped structure and two J-shaped slots. The elastic device adopted in this embodiment is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com