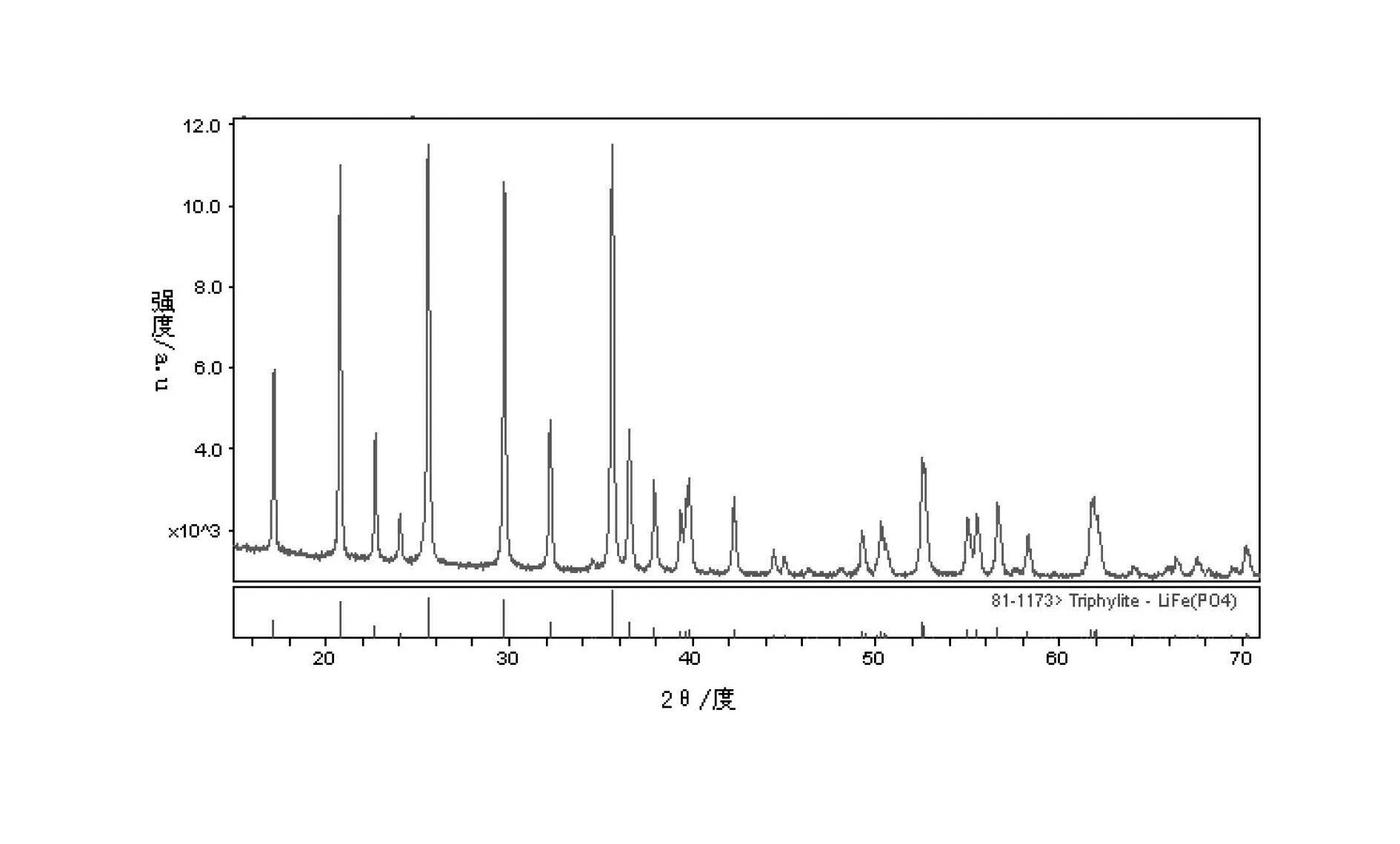

Preparation method for low-temperature nanometer lithium iron phosphate cathode material

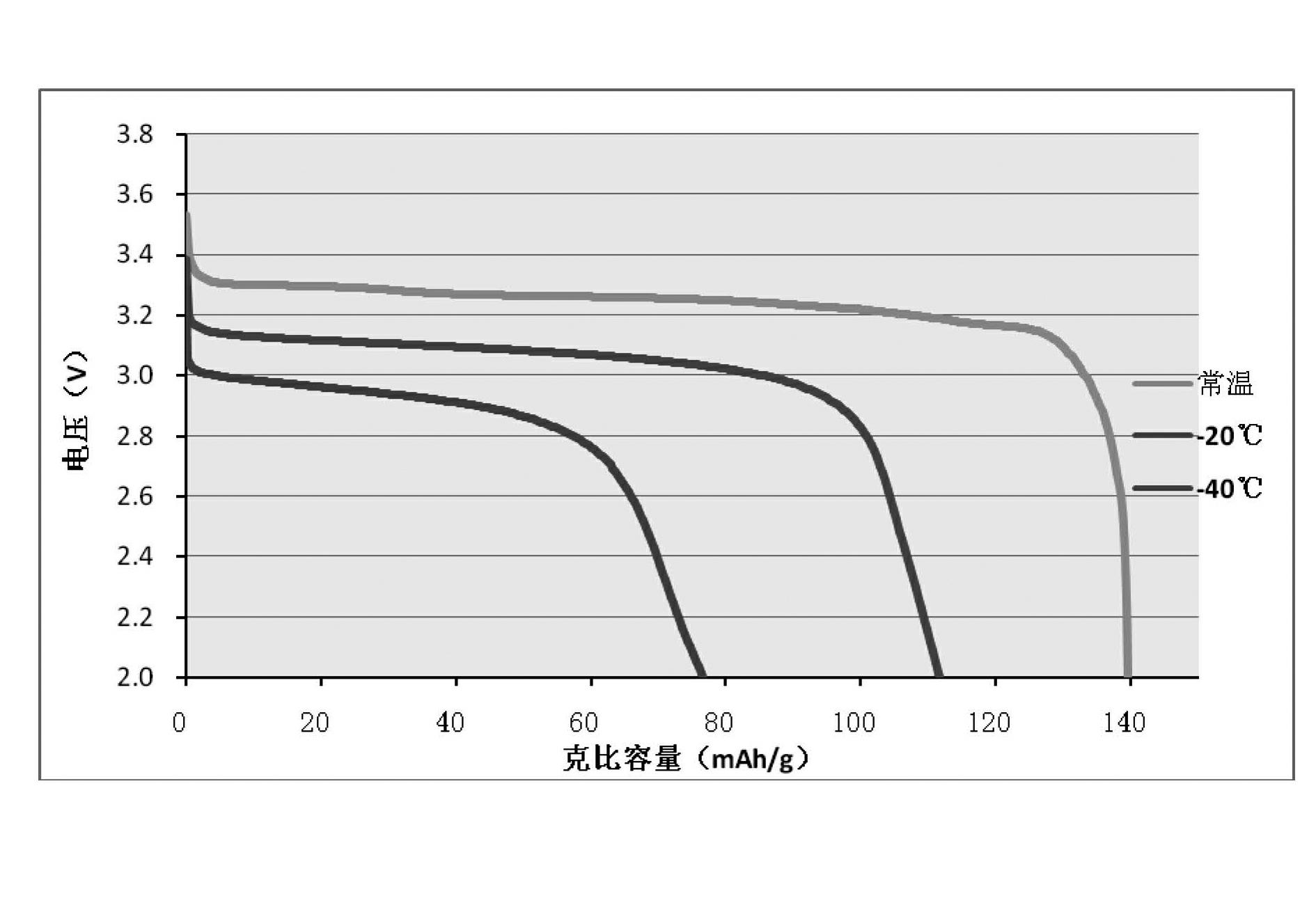

A technology of lithium iron phosphate and cathode material, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as poor low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

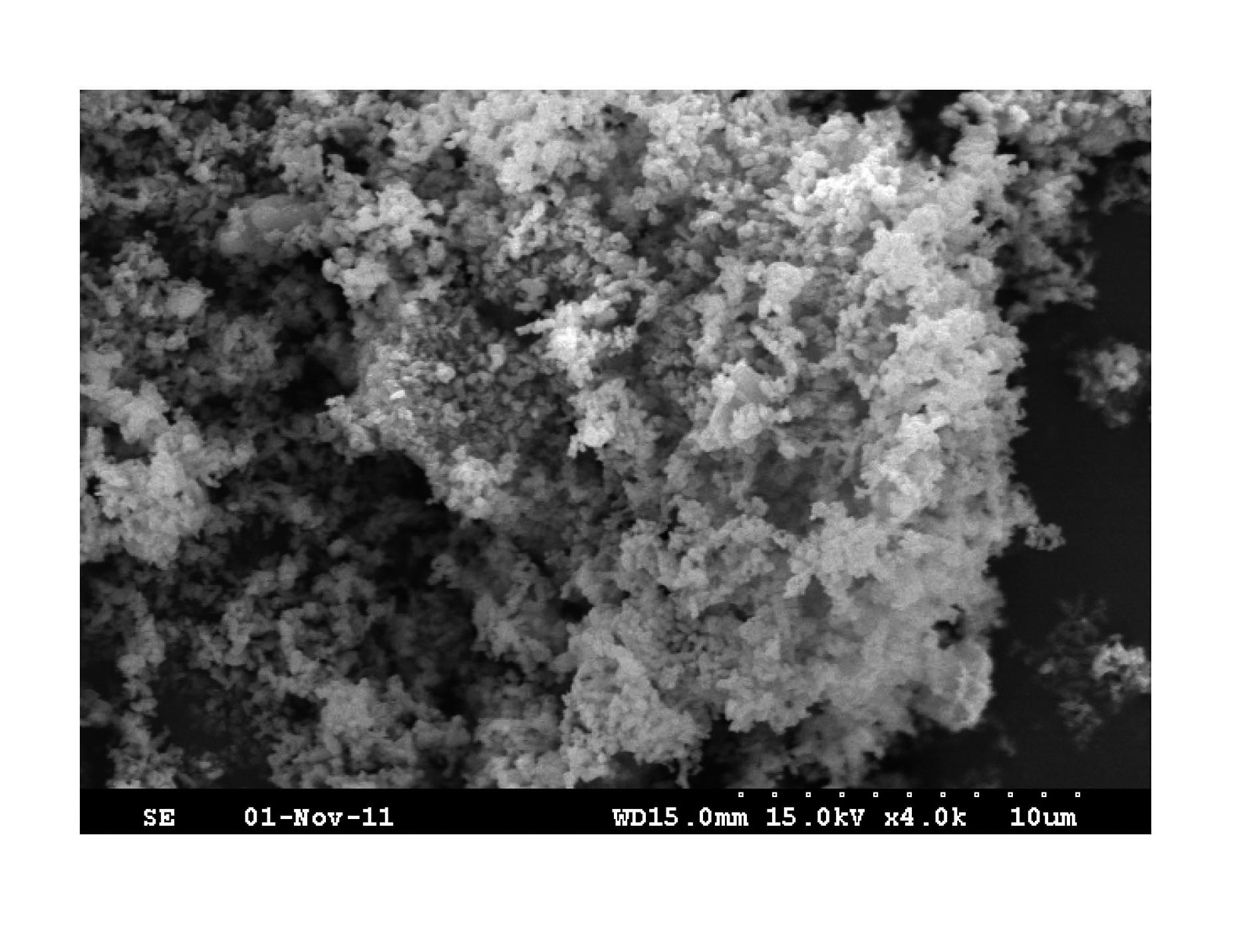

Embodiment 1

[0019] 2.55molLi 2 CO 3 , 2.5molFe 2 o 3 , 5.0mol NH 4 h 2 PO 4 Add to the mixing tank, add 2L deionized water, add 0.01molMnO while stirring 2 , 0.01molTiO 2 and 30g of glucose, stirred evenly, transferred to a ball mill, and performed a high-energy ball mill for 2 to 3 hours, and the D50 of the obtained slurry must be less than 0.1 μm. Then carry out spray drying to form powder, and sieve. put the powder in N 2 In the atmosphere, it was sintered in a rotary furnace at 350° C. for 5 hours. Cool, sieve, transfer to a ball mill jar, add 150g chitosan and 900ml deionized water, stir evenly, transfer to a ball mill, perform a second high-energy ball mill until the D50 of the slurry is less than 0.1 μm, and spray dry to form a spherical shape Powder, sieved. After the powder is subjected to airflow pulverization, it is added to the rotary kiln, and the N 2 Sinter at 650°C for 8 hours in the atmosphere, then heat up to 800°C for 20 hours, cool, sieve and obtain the prod...

Embodiment 2

[0022] 2.55molLi 2 CO 3 , 5.0molFePO 4 Add to the mixing tank, add 2L deionized water, add 0.01molMnO while stirring 2 , 0.01molTiO 2 , 0.02mol MgO and 30g glucose, stirred evenly, transferred to a ball mill, and performed a high-energy ball mill for 2 to 3 hours, and the D50 of the obtained slurry must be less than 0.1 μm. Then carry out spray drying to form powder, and sieve. put the powder in N 2 In the atmosphere, it was sintered in a rotary furnace at 350° C. for 5 hours. Cool, sieve, transfer to a ball mill jar, add 150g chitosan and 900ml deionized water, stir evenly, transfer to a ball mill, perform a second high-energy ball mill until the D50 of the slurry is less than 0.1 μm, and spray dry to form a spherical shape Powder, sieved. After the powder is subjected to airflow pulverization, it is added to the rotary kiln, and the N 2 Sinter at 650°C for 8 hours in the atmosphere, then heat up to 800°C for 20 hours, cool, sieve and obtain the product.

[0023] The...

Embodiment 3

[0025] 2.55molLi 2 CO 3 , 2.5molFe 2 o 3 , 5.0mol NH 4 h 2 PO 4 Add to the mixing tank, add 2L deionized water, add 0.01molMnO while stirring 2 , 0.01molTiO 2 and 30g of sucrose, stirred evenly, transferred to a ball mill, and carried out a high-energy ball mill for 2 to 3 hours, and the D50 of the obtained slurry must be less than 0.1 μm. Then carry out spray drying to form powder, and sieve. put the powder in N 2 In the atmosphere, it was sintered in a rotary furnace at 350° C. for 5 hours. Cool, sieve, transfer to a ball mill tank, add 180g of modified starch and 900ml of deionized water, stir evenly, transfer to a ball mill, perform a second high-energy ball mill until the D50 of the slurry is less than 0.1 μm, and spray dry to form a spherical shape Powder, sieved. After the powder is subjected to airflow pulverization, it is added to the rotary kiln, and the N 2 Sinter at 650°C for 8 hours in the atmosphere, then heat up to 800°C for 20 hours, cool, sieve and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com